Method of preparing hydroxy apatite liquid crystal in aqueous solution

A technology of hydroxyapatite and aqueous solution, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as hydroxyapatite liquid crystal reports that have not been seen yet, and achieve excellent biocompatibility, low preparation cost, and easy post-production Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 300ml of calcium nitrate solution with a concentration of 0.05M into the gelatin solution with a concentration of 0.03g / ml, stir vigorously and heat up to 85°C;

[0020] (2) After 20min, add dropwise the ammonium phosphate solution with a concentration of 0.025M and a volume of 300ml at a rate of 50ml / h;

[0021] (3) Then slowly increase the temperature. When the temperature rises to 100°C, keep the constant temperature for 2 hours and continue to stir. After the reaction is over, let it cool naturally. After the reaction system drops to room temperature, use 2000r / m. Centrifuge for 2 hours, separate the sediment from the sol, and concentrate the sol in vacuum at less than 80°C for 2 hours;

[0022] (4) Under the condition of ultrasonic oscillation, sols with mass volume ratios of 1%, 7%, and 15% were prepared respectively, and left to stand for 10 days, and the liquid crystal phase transition in the sol was observed.

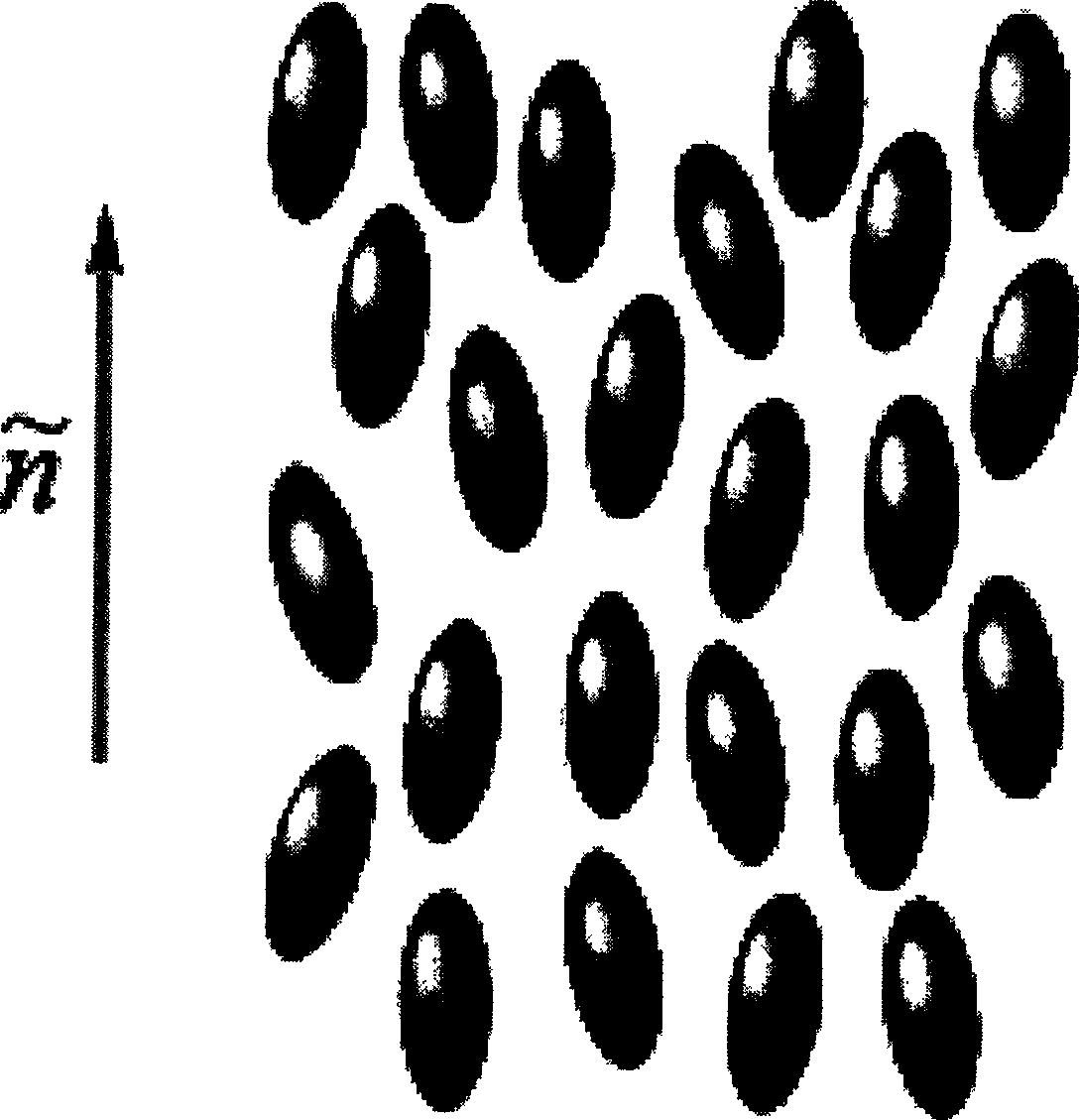

[0023] A hydroxyapatite nematic liquid cr...

Embodiment 2

[0025] (1) Add 100ml of calcium nitrate solution with a concentration of 0.15M into the gelatin solution with a concentration of 0.01g / ml, stir vigorously and heat up to 95°C,

[0026] (2) After 30min, add dropwise the concentration of 0.075M with the speed of 40ml / h, and the volume is 100ml of disodium hydrogen phosphate solution,

[0027] (3) Then slowly increase the temperature. When the temperature rises to 100°C, keep the constant temperature for 3 hours and continue to stir. After the reaction is over, let it cool naturally. After the reaction system drops to room temperature, use the speed of 3000r / m. Centrifuge for 1 h, separate the sediment from the sol, and concentrate the sol in vacuum at less than 80°C for 2 h;

[0028] (4) Under the condition of ultrasonic oscillation, sols with mass volume ratios of 1%, 7%, and 15% were prepared respectively, and left to stand for 10 days, and the liquid crystal phase transition in the sol was observed.

[0029] A hydroxyapatite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com