Method for preparing composite film of silver Nano granule / titanium dioxide

A technology of titanium dioxide and composite thin film, which is applied in liquid chemical plating, semiconductor/solid-state device manufacturing, coating and other directions, can solve the problem of staying silver content and other problems, achieve good photocatalytic performance and electrical conductivity, and the method and equipment are simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Mix butyl titanate and ethanol in a container at a molar ratio of 1:6, put the container in an ice-water bath and stir for 30 minutes to obtain liquid A,

[0018] 2) Mix water, diethanolamine, ethanol and silver nitrate powder in a molar ratio of 1:1:12:0.6 and keep stirring until the silver nitrate is completely dissolved to obtain liquid B.

[0019] 3) Add liquid B drop by drop into liquid A which has been placed in an ice-water bath, and then continue to stir until a sol with stable color is obtained, and then age the sol at 4°C for use;

[0020] 4) Immerse a clean quartz glass sheet in the above sol and pull it. The pulling speed is controlled at 2cm / min. After each layer is pulled, it is heat-treated at 450°C for 30min to obtain Ag / TiO 2 film.

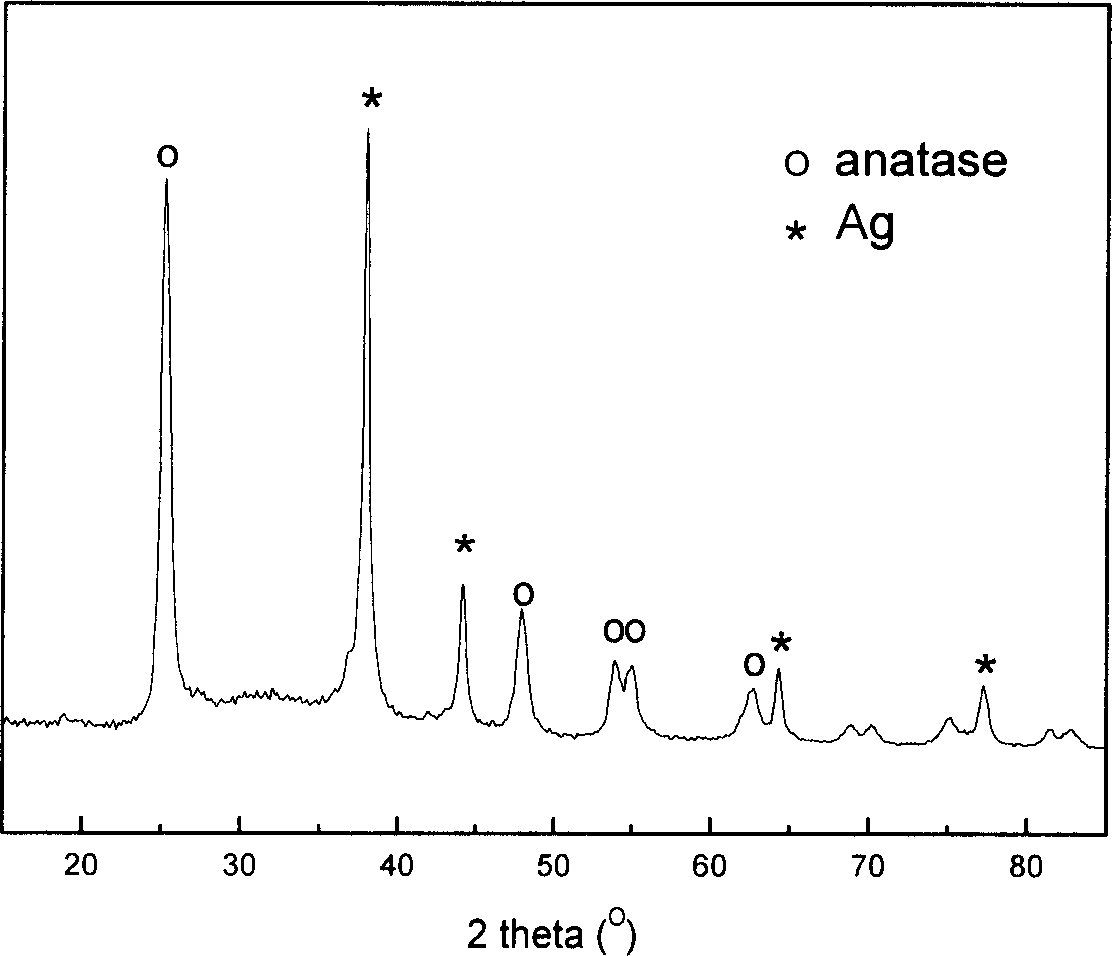

[0021] The prepared Ag / TiO 2 The XRD pattern of the film is as figure 1 As shown, the film is composed of titanium dioxide in anatase phase and metallic silver. Ag / TiO 2 The BSE photo of the membrane is as figure ...

Embodiment 2

[0023] 1) Mix titanium chloride and ethylene glycol methyl ether in a container at a molar ratio of 1:15, put the container in an ice-water bath and stir for 30 minutes to obtain liquid A,

[0024] 2) Mix water, citric acid, ethylene glycol methyl ether and silver nitrate powder in a molar ratio of 1:0.1:18:1.5 and keep stirring until the silver nitrate is completely dissolved to obtain liquid B.

[0025] 3) Add liquid B dropwise into liquid A which has been placed in an ice-water bath, and then continue to stir until a sol with stable color is obtained, and then age the sol at -4°C for use;

[0026] 4) Immerse a clean ordinary glass sheet in the above sol and pull it. The pulling speed is controlled at 8cm / min. After each layer is pulled, it is heat-treated at 600°C for 10 minutes to obtain Ag / TiO 2 film.

[0027] The prepared Ag / TiO 2 The content At% of Ag in the film was 10.36.

Embodiment 3

[0029] 1) Mix isopropyl titanate and propylene glycol methyl ether in a container at a molar ratio of 1:4, put the container in an ice-water bath and stir for 30 minutes to obtain liquid A,

[0030] 2) Mix water, polyethylene glycol, propylene glycol methyl ether and silver nitrate powder in a molar ratio of 1:0.5:6:0.2 and keep stirring until the silver nitrate is completely dissolved to obtain liquid B.

[0031] 3) Add liquid B drop by drop into liquid A which has been placed in an ice-water bath, and then continue to stir until a sol with stable color is obtained, and then age the sol at 20°C for use;

[0032] 4) Immerse the clean ceramic sheet in the above sol and pull it. The pulling speed is controlled at 2cm / min. After each layer is pulled, it is heat-treated at 500°C for 30min to obtain Ag / TiO 2 film.

[0033] The prepared Ag / TiO 2 The content At% of Ag in the film was 3.64.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com