Intercalation kaolin/modified titanium oxide nano composite particles electrorheological fluid

A nano-composite, electrorheological fluid technology, used in lubricating compositions, petroleum industry, additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

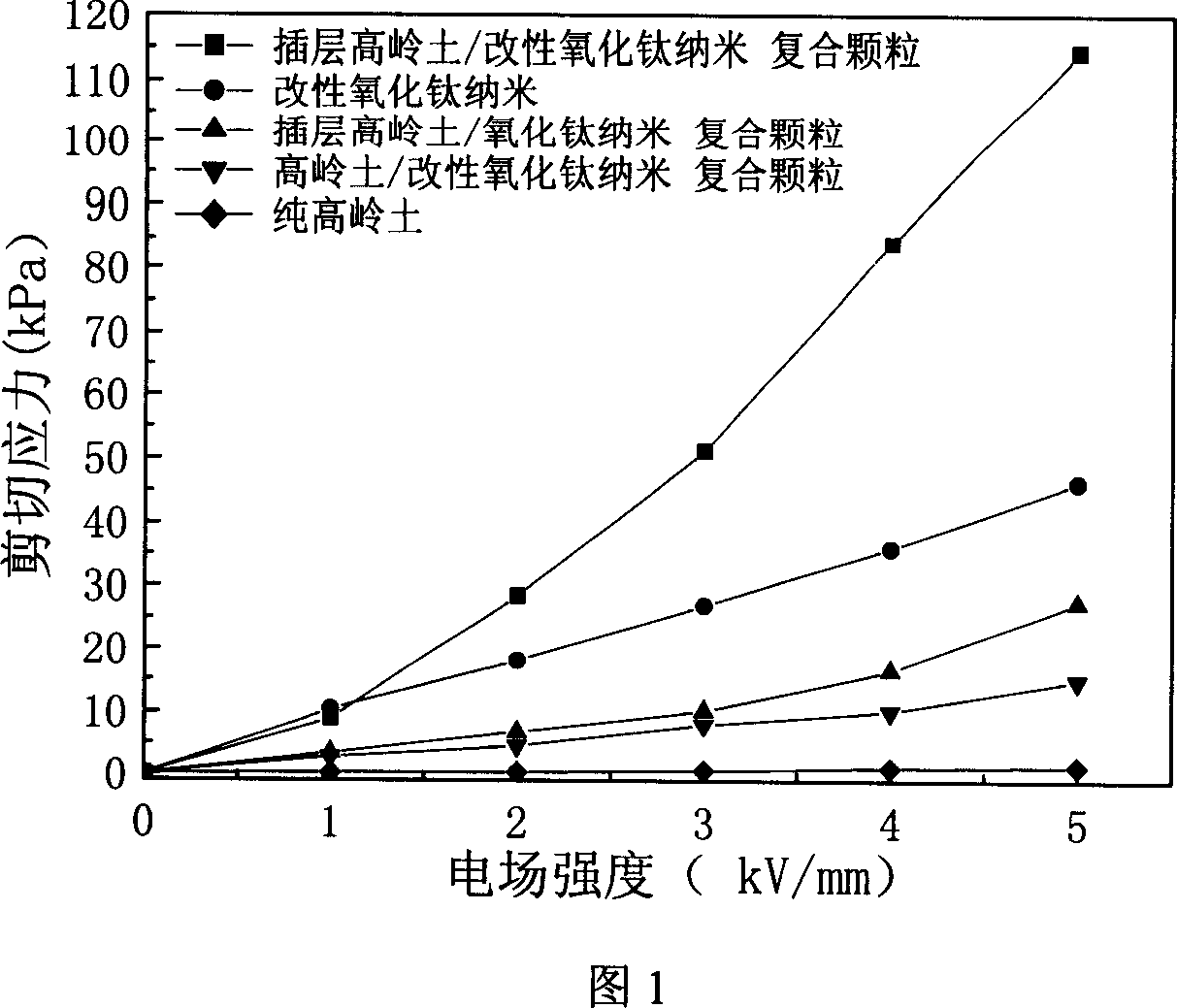

[0018] Example 1: (intercalated kaolin / modified titanium oxide nanocomposite particles electrorheological fluid)

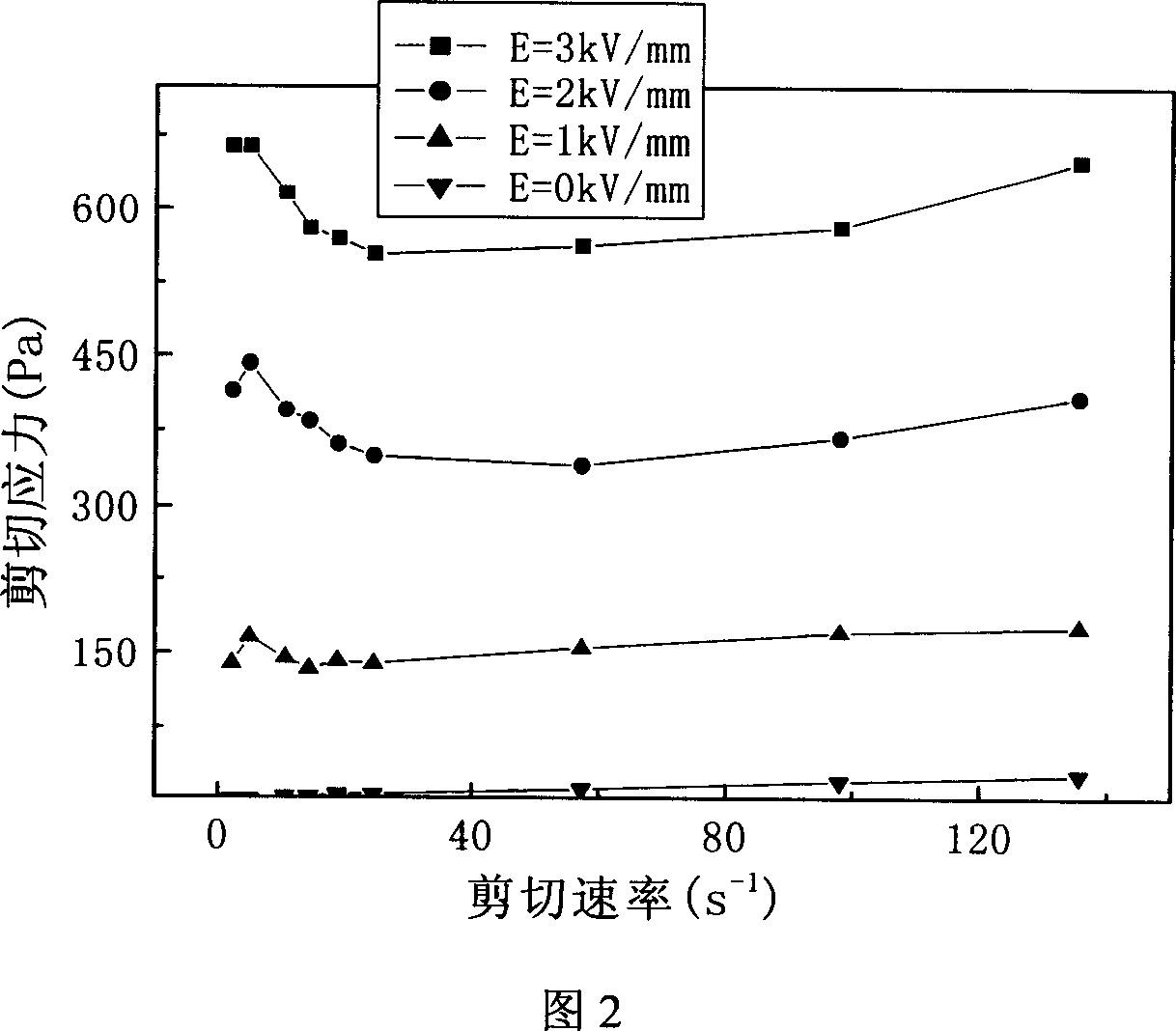

[0019] Measure 10ml-70ml formamide and 30ml deionized water into a 100ml beaker, add 1.5g kaolin, stir magnetically for 48-60 hours, centrifuge and wash the product with deionized water 1-2 times to obtain formamide-intercalated kaolin . Disperse the intercalated kaolin in 200ml deionized water, add 4g sodium dodecylbenzenesulfonate and stir for 5 hours. Add 5ml of butyl titanate, 50ml of absolute ethanol, 1ml of glacial acetic acid, and 0.6g of chromium nitrate to a 100ml beaker and stir for 3 hours, then slowly drop them into the above 200ml aqueous solution, and continue the reaction for 10 hours to 14 hours after the dropwise addition. Hours, vacuum filtration to obtain a loose green filter cake. Dry the filter cake at 60°C-90°C for 3 hours to 5 hours, grind it into powder in a mortar, then dry it at 60°C-80°C for 2-4 hours, and get intercalated kaolin after...

Embodiment 2

[0020] Example 2: (formamide intercalated kaolin / titanium oxide nanocomposite particles electrorheological fluid)

[0021] Measure 10ml-70ml formamide and 30ml deionized water into a 100ml beaker, add 1.5g kaolin, stir magnetically for 48-60 hours, centrifuge and wash the product with deionized water 1-2 times to obtain formamide-intercalated kaolin . Disperse the intercalated kaolin in 200ml deionized water, add 4g sodium dodecylbenzenesulfonate and stir for 5 hours. Add 5ml of butyl titanate, 50ml of absolute ethanol, and 1ml of glacial acetic acid to a 100ml beaker in turn and stir for 3 hours, then slowly drop them into the above 200ml aqueous solution, continue to react for 10-14 hours after the dropwise addition, and vacuum filter Get a loose filter cake. Dry the filter cake at 60°C-90°C for 3-5 hours, grind it into a powder in a mortar and then dry it at 60°C-80°C for 2 hours-4 hours, and formamide intercalation can be obtained after thorough grinding Kaolin / TiO nano...

Embodiment 3

[0022] Example Three: (Kaolin / Modified Titanium Oxide Nanocomposite Particle Electrorheological Fluid)

[0023] Disperse 1.5 g of kaolin in 200 ml of deionized water and add 4 g of sodium dodecylbenzenesulfonate and stir for 5 hours. Add 5ml of butyl titanate, 50ml of absolute ethanol, 1ml of glacial acetic acid, and 0.6g of chromium nitrate to a 100ml beaker and stir for 3 hours, then slowly drop them into the above 200ml aqueous solution, and continue the reaction for 10 hours to 14 hours after the dropwise addition. Hours, vacuum filtration to obtain a loose green filter cake. Dry the filter cake at 60°C to 90°C for 3 hours to 5 hours, grind it into powder in a mortar and then dry it at 60°C to 80°C for 2 to 4 hours. Titanium oxide nanocomposite particles. The prepared nanocomposite particles and methyl silicone oil were evenly mixed at 2 g / 1 ml, and the relationship between the shear stress and the electric field intensity of the prepared electrorheological fluid is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com