Semiconductor laser element

一种激光元件、半导体的技术,应用在半导体激光器、激光器零部件、激光器等方向,能够解决斜率效率低、寿命降低、端面老化等问题,达到抑制老化、高输出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

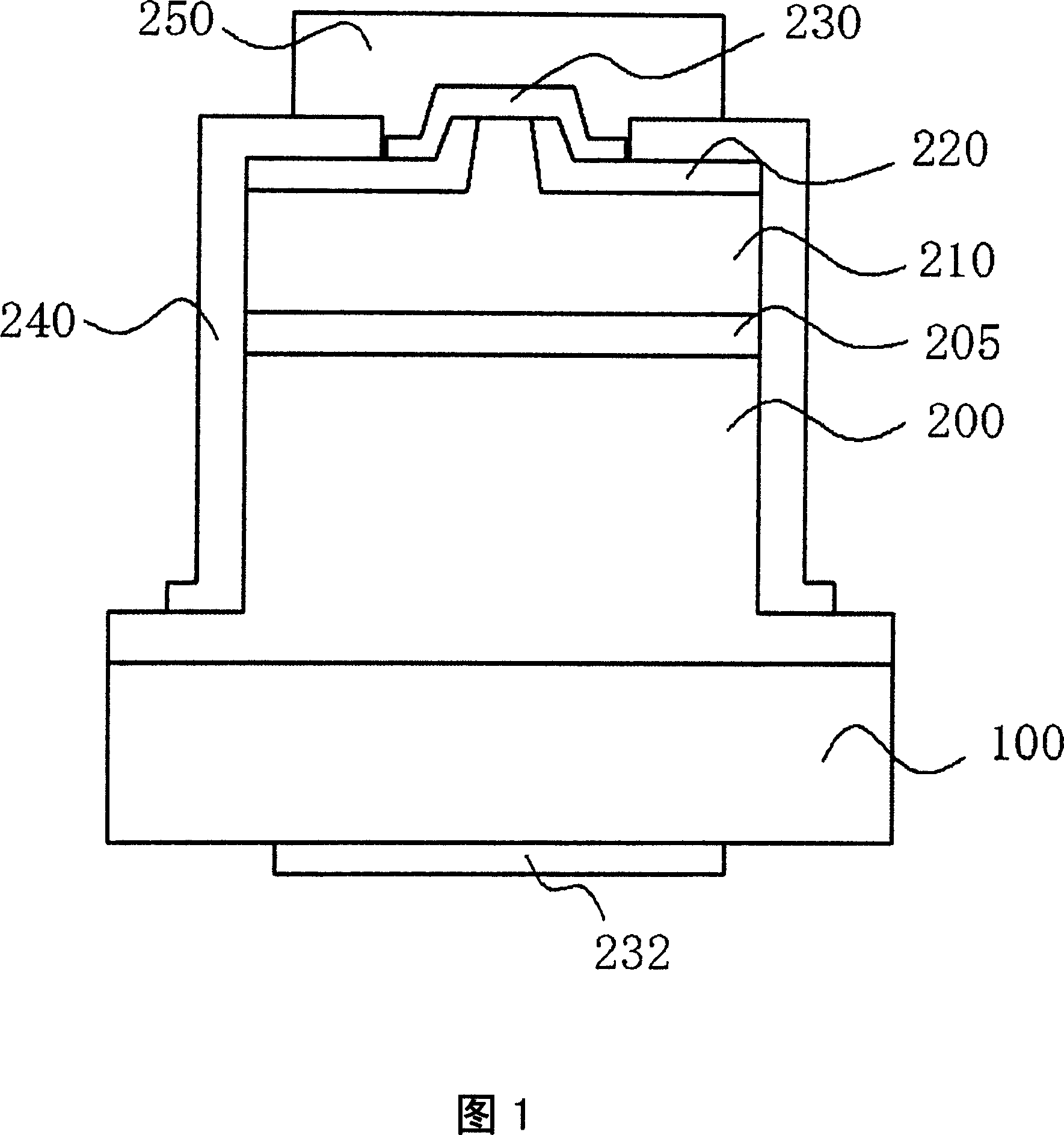

[0098] As the substrate, a wafer-like GaN substrate 100 having a C plane as a main surface was used. The substrate is not particularly limited thereto, and a GaN substrate whose main surfaces are the R plane and the A plane can be used as needed.

[0099] (n-type cladding layer 201) Next, the GaN substrate was transferred to an MOCVD apparatus. The atmosphere temperature in the furnace was set at 1050°C, and TMA (trimethylaluminum), TMG, and ammonia were used as raw material gases to grow undoped Al 0.04 Ga 0.96 An n-type cladding layer composed of N. This layer may also be doped with n-type impurities.

[0100] (Active layer 205) Next, set the temperature to 800°C, use TMI (trimethylindium), TMG, and ammonia as raw materials, and use silane gas as an impurity gas to grow Si-doped In with a film thickness of 140 Å. 0.02 Ga 0.98 The barrier layer composed of N. Next, the use of silane gas was stopped, and undoped In was grown with a film thickness of 80 Ȧ 0.1 Ga 0.9 Wel...

Embodiment 2

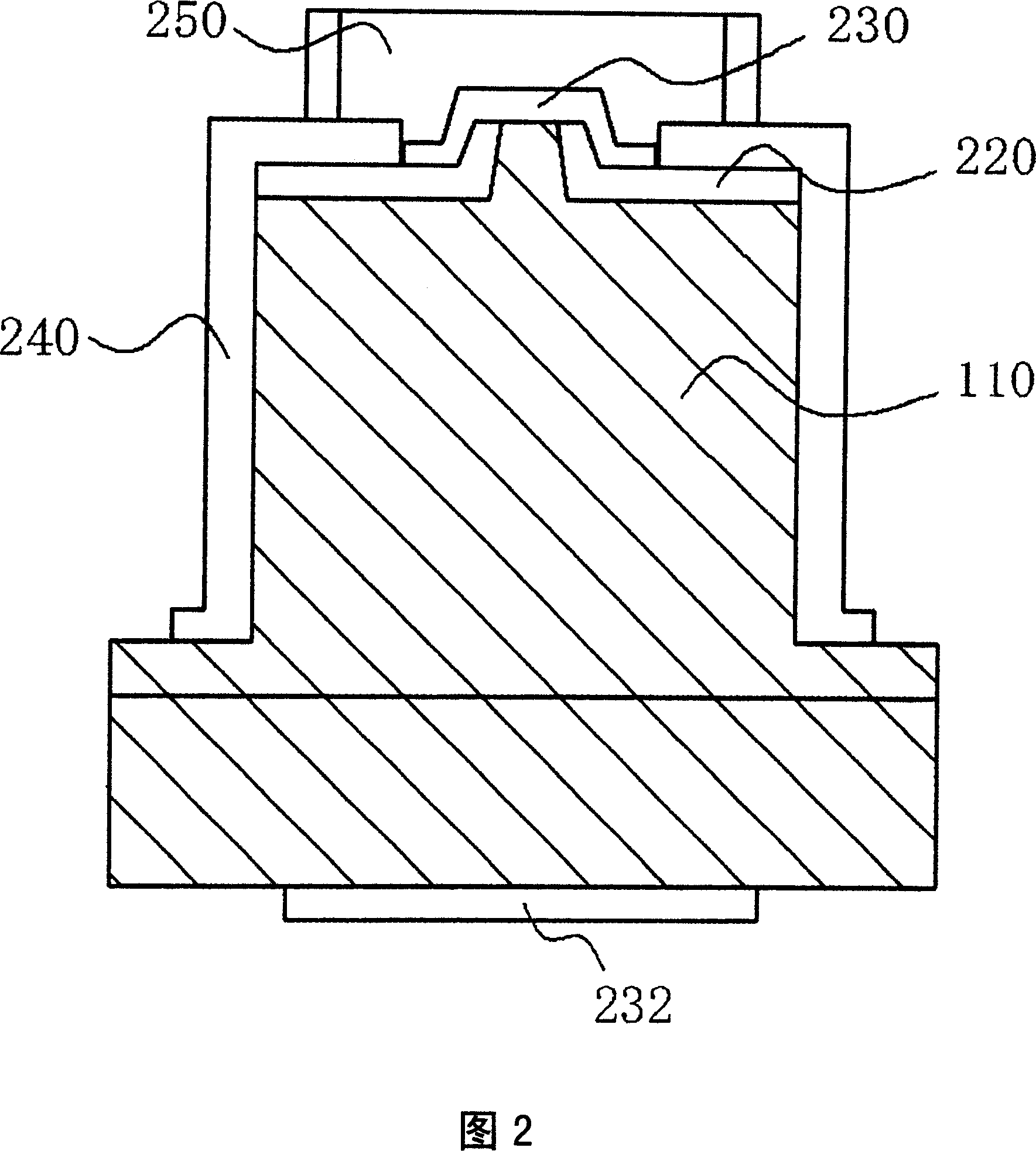

[0118] A nitride semiconductor laser element was formed in the same manner as in Example 1, except that the dielectric film 110 on the light-exit side end face had the following configuration. An ECR sputtering device was used. After cleaning the light exit side end face with plasma of active gas such as oxygen, the x o y The first dielectric film and the second dielectric film are formed. First, use 5N Al in the metal target, set the flow rate of Ar to 15 sccm; 2 The flow rate was set to 10 sccm; the microwave power was 600 W; and the RF was 600 W, the first dielectric film was formed with a film thickness of 20 nm. Thereafter, using 5N Al in the metal target, the flow rate of Ar is set to 10 sccm; the O 2 The flow rate was set at 3 sccm, the microwave power was 450 W, and the RF was 450 W, and the second dielectric film was formed with a film thickness of 100 nm. Here, with respect to light of 405 nm, the refractive index of the first dielectric film is 1.63, and the re...

Embodiment 3

[0120] A nitride semiconductor laser device was formed in the same manner as in Example 1, except that the dielectric film had the following configuration.

[0121] For the end face on the light exit side, after using an ECR sputtering device to clean the end face on the light exit side with plasma of an active gas such as oxygen, use 5N Al in the metal target, and set the flow rate of Ar to 15 sccm; 2 The flow rate is set to 10sccm; the microwave power is 600W; RF is 600W, after the first dielectric film 111 is formed with a film thickness of 20nm, 5N Al is used in the metal target, and the flow rate of Ar is set to 10sccm; Will O 2 The flow rate was set at 3 sccm; the microwave power was 450 W; and the RF was 450 W, the second dielectric film was formed with a film thickness of 40 nm, thereby forming the dielectric film 110 . Here, with respect to light of 405 nm, the refractive index of the first dielectric film is 1.63, and the refractive index of the second dielectric fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com