Glass permeated zirconia ceramic dental material and its prepn process

A technology of zirconia and glass, used in dental preparations, dentistry, dental prostheses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0016] The preparation of embodiment 1~6 infiltration glass

[0017] According to the mass percentage content of each component listed in Table 1, weigh a certain amount of analytically pure SiO 2 , B 2 o 3 、BaCO 3 、La 2 o 3 、Al 2o 3 , Y 2 o 3 , ZrO 2 , CaCO 3 、TiO 2 , CeO 2 and Fe 2 o 3 , respectively, fully mixed and ground with a planetary ball mill, taken out and dried; respectively put the mixed powder in a platinum alloy dry pot, placed in a resistance furnace, and heated to 800°C for 1 to 3 hours in an air atmosphere, and then raised to To 1300 ℃ ~ 1500 ℃, constant temperature 3 ~ 6 hours, then take out at 1000 ℃ and pour into cold water for rapid cooling to form small glass pieces, and finally ball milled into particles with a size of about 1 micron, dried for later use.

[0018] Example

[0019] *The colorant is CeO 2 and Fe 2 o 3 .

Embodiment 7~10 4

[0020] Preparation of Example 7-10 Tetragonal Porous Zirconia Green Body

[0021] Tetragonal zirconia powders stabilized with 3mol% yttria are used as raw materials, and the average particle sizes are 0.97 μm, 2.5 μm, 5.4 μm and 10.9 μm, respectively. Add 3wt% glycerin as a binder, mix evenly, and press it into a sheet-shaped green body under an axial pressure of about 50 MPa, and the relative density of the obtained green body is in the range of 45-50%. According to the relationship between the average particle size of the powder and the sintering temperature shown in Table 2, the green body was sintered at the corresponding sintering temperature for 2 hours in a resistance furnace and in an air atmosphere to form a tetragonal porous zirconia green body. The heating rate is as follows: the first step is to raise the temperature from room temperature to 300°C at a rate of 2K / min, and then keep it at 300°C for 1h; the second step is to raise the temperature to 1100°C at a rate ...

Embodiment 11

[0023] Preparation of Example 11 Zirconia-Glass Composite Material

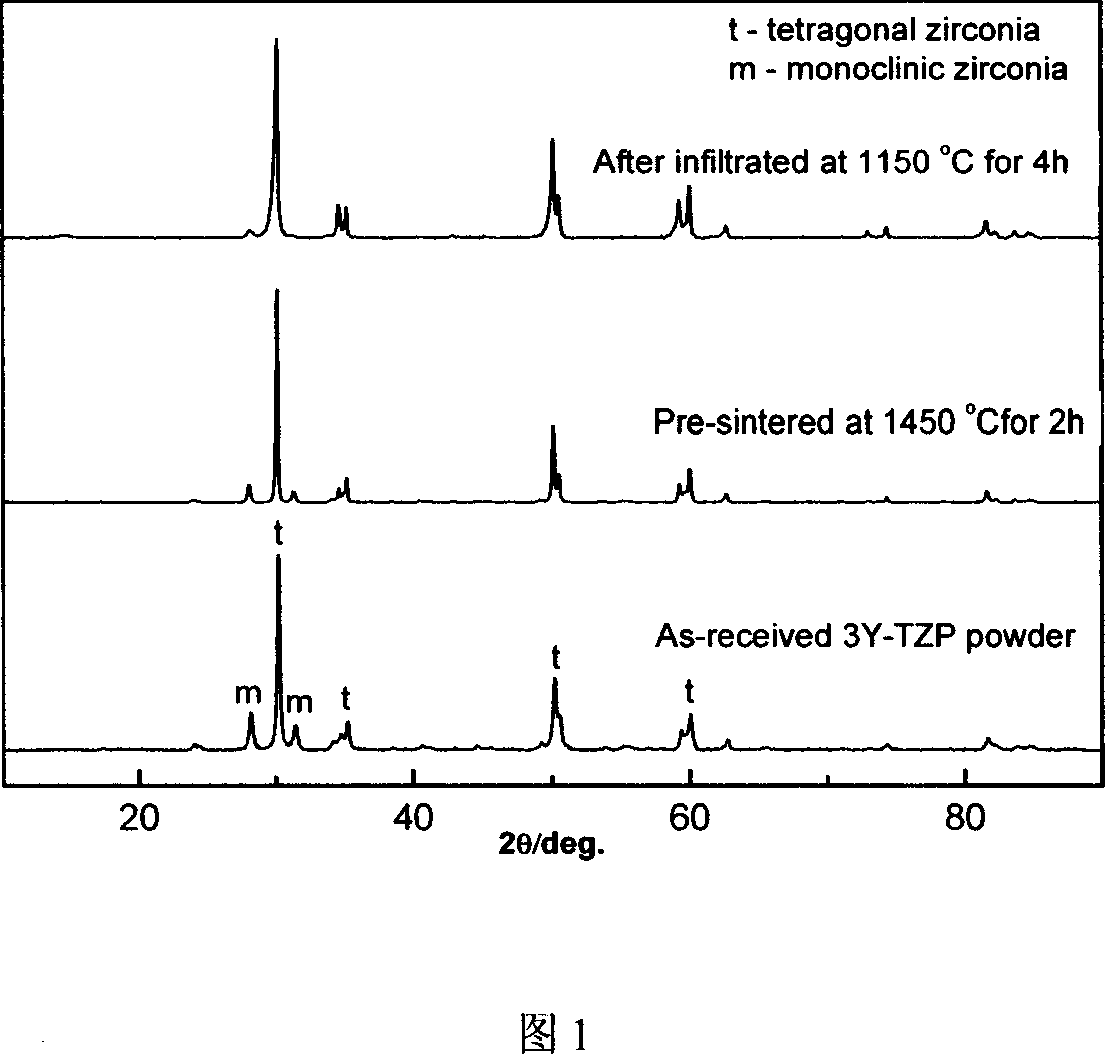

[0024] The porous tetragonal zirconia body prepared in Examples 7 to 10 is processed into a sheet sample of 30 mm × 30 mm × 4 mm, and then the glass powder prepared in Examples 1 to 6 is adjusted into a powder slurry with dehydrated alcohol, Spread it evenly on the upper surface of the sample (the thickness of the coating depends on the penetration thickness), then dry it in an oven at 70°C for 15 minutes, take it out and put it in a resistance furnace, heat it up to 1150°C in an air atmosphere, keep it warm for 4 hours, and then cool slowly to At room temperature, a dense zirconia-glass dental material can be obtained. XRD analysis was carried out on the phase structure of the infiltrated zirconia-glass dental material. As shown in Figure 1, the main phase of the tetragonal zirconia powder used and the tetragonal porous zirconia green body sintered at 1450 °C were all tetragonal. phase, but still contains p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com