Alignment system for photoetching device and stage jointing grating system

An alignment system and lithography technology, applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., can solve the problems of increasing the complexity of the drive system and low alignment accuracy, and achieve the suppression of interference and destructive effects The influence of the structure, good structural stability, and the effect of improving the strength of the alignment signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

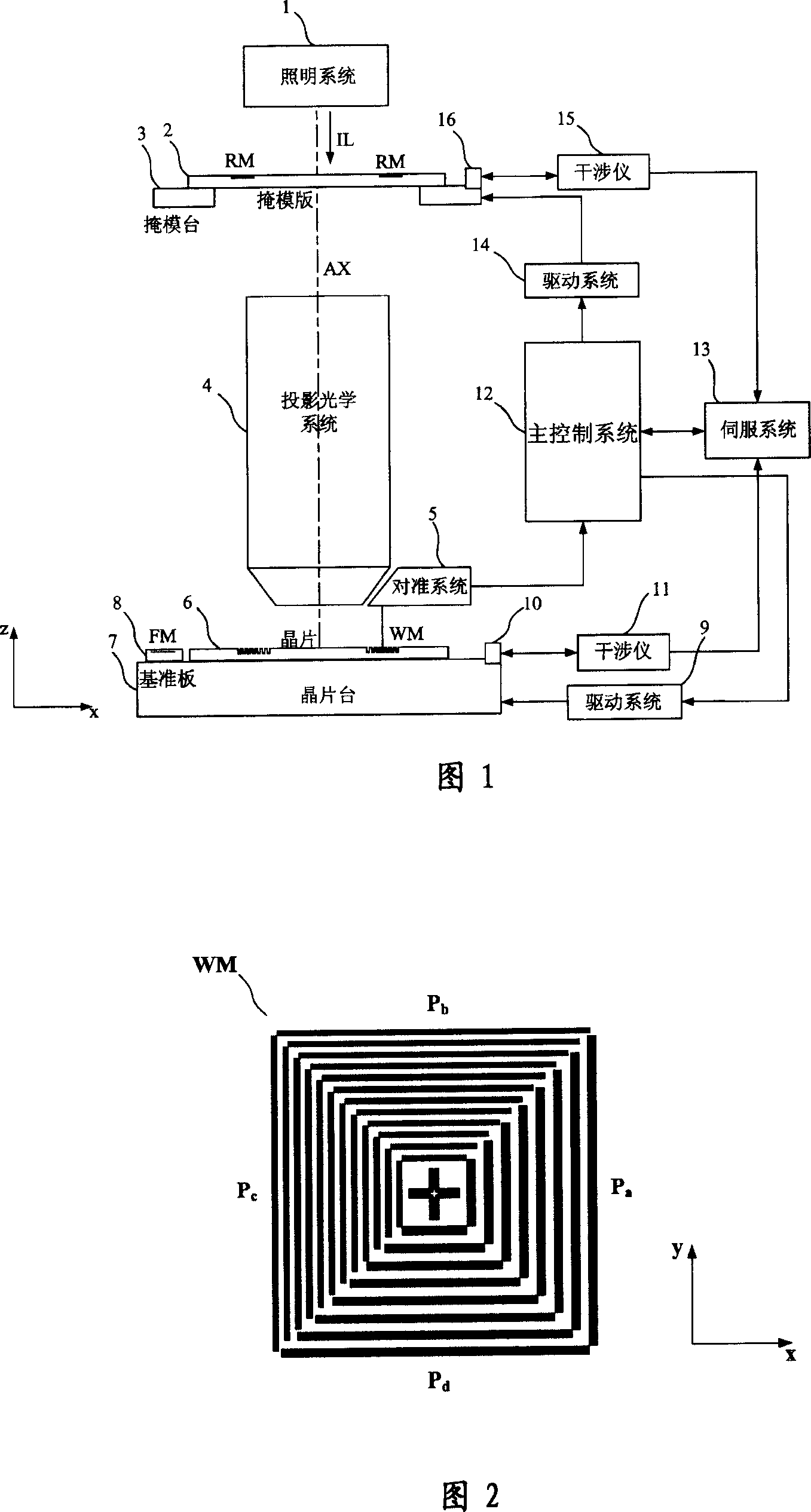

[0065] Fig. 1 is a schematic structural view of a lithography apparatus according to a specific embodiment of the present invention, as can be seen from Fig. 1, its composition includes: an illumination system 1 for providing an exposure beam; a mask holder and a mask table 3 for supporting a reticle 2, There is a mask pattern on the reticle 2 and an alignment mark RM with a periodic structure; a projection optical system 4 for projecting the mask pattern on the reticle 2 onto a wafer 6; a wafer holder and a wafer for supporting the wafer 6 Stage 7, on wafer stage 7 there is fiducial plate 8 engraved with fiducial mark FM, on wafer 6 there is alignment mark WM of periodic optical structure; Alignment system 5 of the system; mirrors 10, 16 and laser interferometers 11, 15 for position measurement of mask stage 3 and wafer stage 7, and displacement of mask stage 3 and wafer stage 7 controlled by main control system 12 Servo system 13 and drive system 9,14.

[0066] The illumina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com