Bioreactor for constructing tendon from tissue engineering

A bioreactor and tendon technology, applied in the direction of microorganisms, tissue culture, artificial cell constructs, etc., can solve the problems of not being able to observe the reaction of cells and biological materials, nude mice without perfect immune function, and not conforming to physiological characteristics, etc., to achieve Improved local microenvironment, good strength and toughness, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of bioreactor

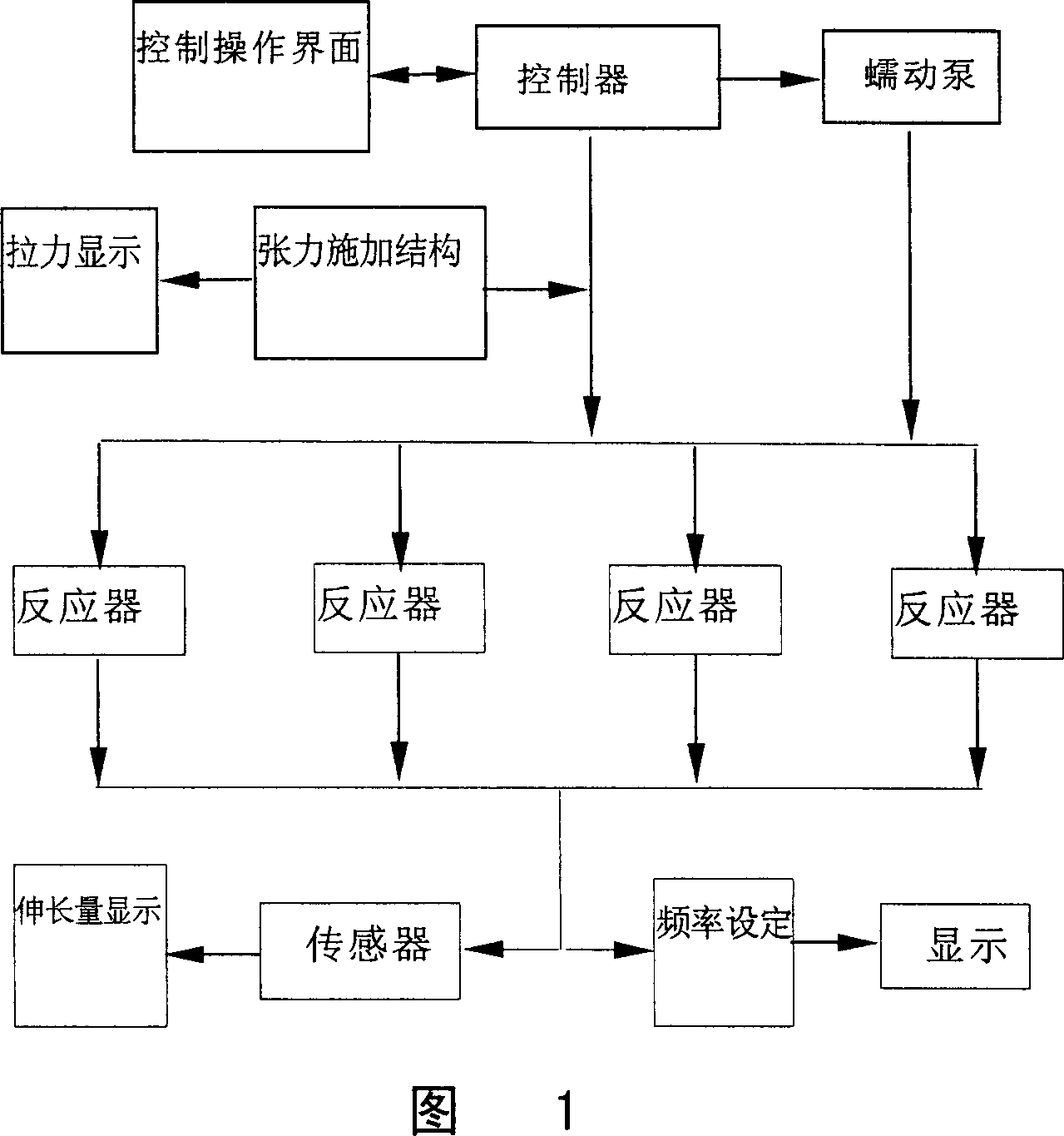

[0062] As shown in Figure 1, the bioreactor of the present embodiment includes a cell culture room, a control system, a liquid change control system and a parameter measurement system, wherein the cell culture room is connected to the control system, the liquid change control system and the parameter measurement system respectively .

[0063] The bioreactor is made of completely transparent organic materials, and its outer structure measures 450 mm in length, 130 mm in height and 350 mm in width. The outer dimensions of the cell culture chamber in the reactor are 140 mm in length, 60 mm in height and 90 mm in width. The number of reactors can be reasonably combined according to specific requirements to form multiple different and relatively independent single culture chambers placed in the incubator. The tension display can be accurate to 0.00 kg, and the measurement range is 0-4 kg. The displacement measurement can be accurate to 0.01 mm, ...

Embodiment 2

[0065] Method for culturing tenocytes in a bioreactor

[0066] (1) Under sterile conditions, cut all the deep flexor tendons of Leghorn chicken toe 3-4cm, cut into 1×2×2mm 3 The large and small tissue pieces were washed twice with phosphate buffer solution (PBS, containing 100 U / ml each of penicillin and streptomycin), and the tissue pieces were cultured adherently;

[0067] (2) The tenocytes were passed to the second passage, and the cells were collected by digesting with 0.25% trypsin;

[0068] (3) Arrange 20 mg of PGA in parallel into bundles, 3.5 cm long and 0.3 cm in diameter;

[0069] (4) Use the above cells and culture medium to make a concentration of 5.0×10 7 / ml of cell suspension, then mixed with PGA to form a complex, fixed in the culture chamber of the reactor, and placed in an incubator at 37°C and 5% carbon dioxide concentration for 4 hours;

[0070] (5) Then add DMEM culture fluid containing 20% fetal bovine serum and continue to place it in the incubator ...

Embodiment 3-6

[0073] Bioreactor culture of tenocytes

[0074] Example 3

[0075] Number of stretches per day

[0076] The measurement results of the tendon grafts in Examples 3-6 are similar to those in Example 2, and the tensile strengths at 8 weeks are respectively 1.5997±0.0904MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com