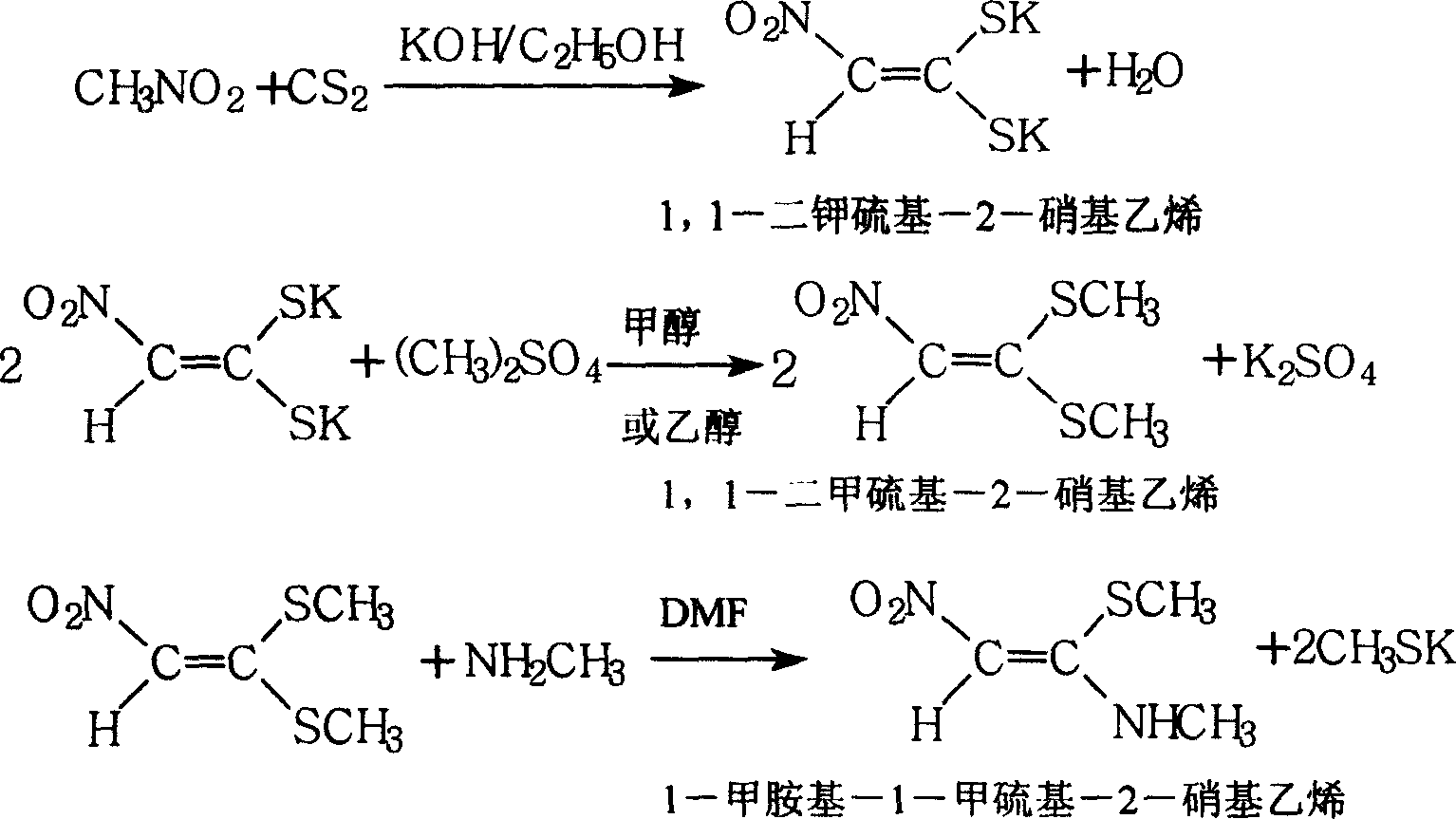

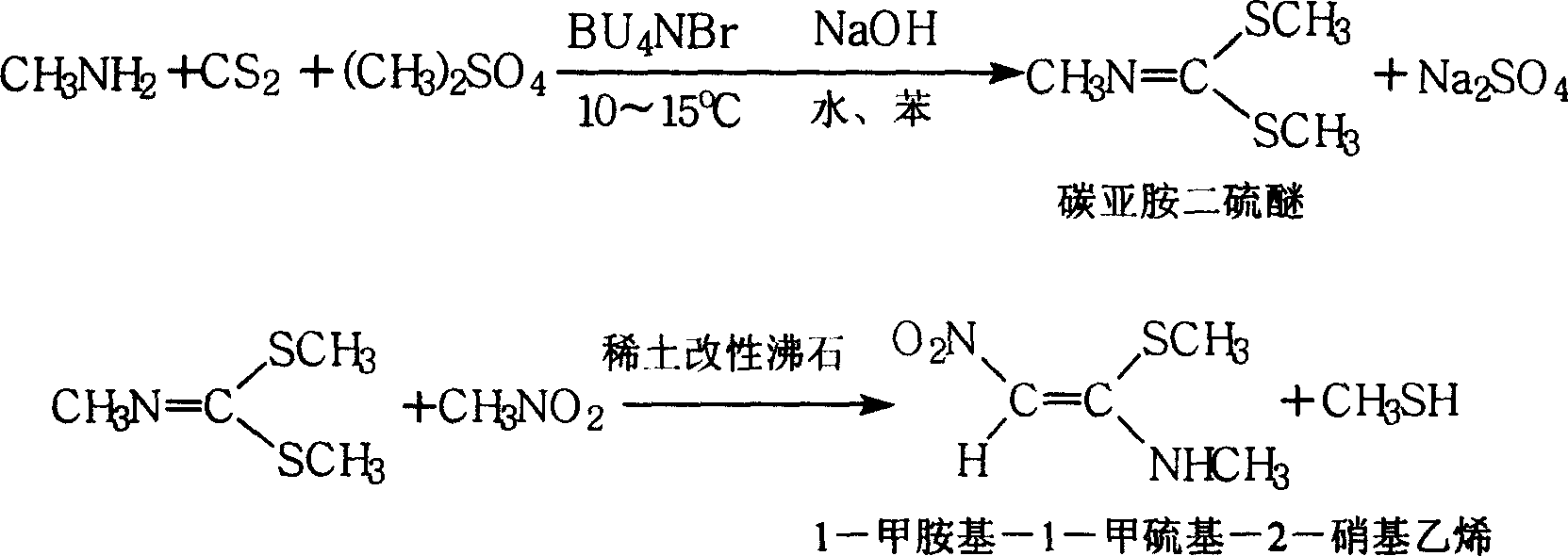

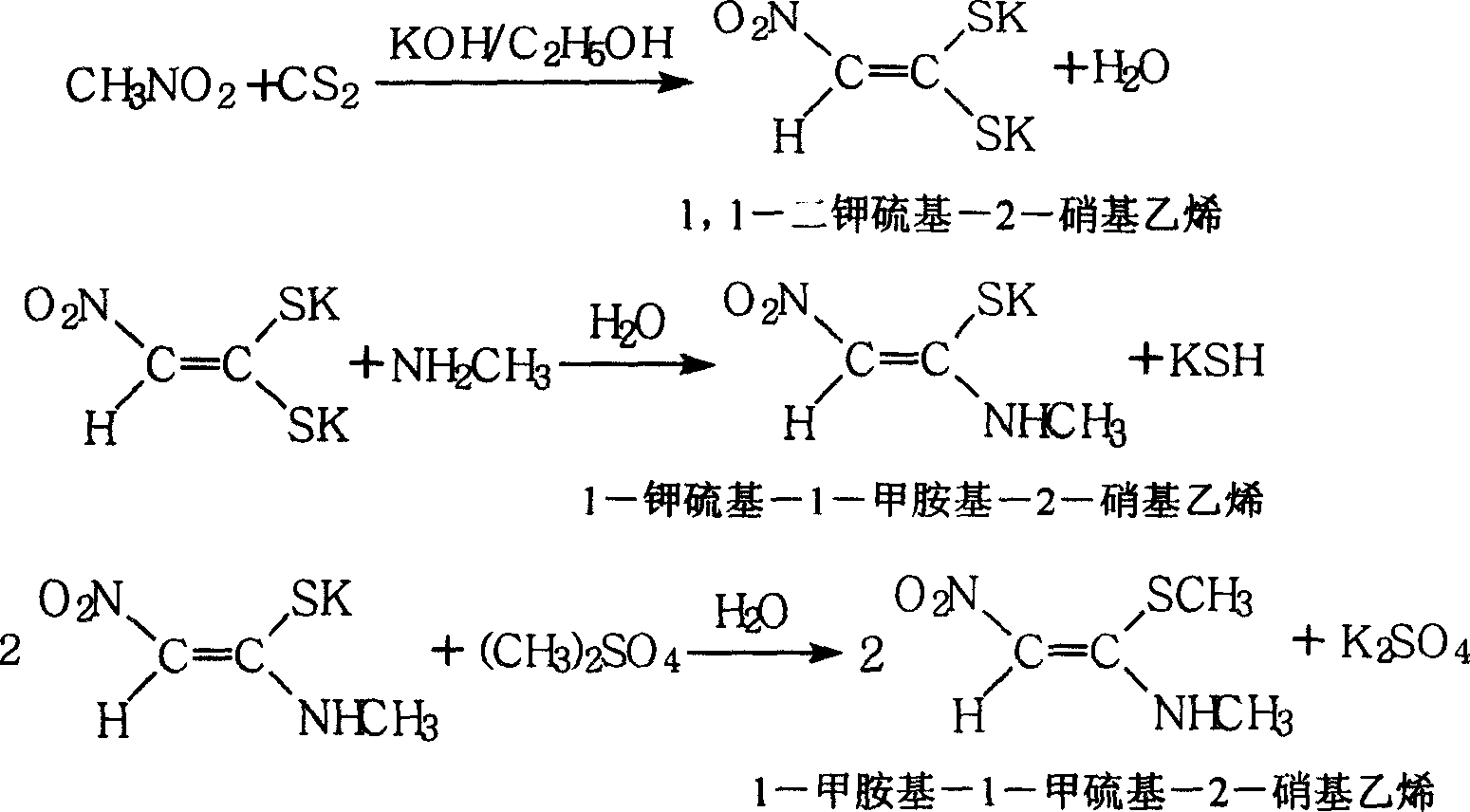

1-methylamino-1- methylthio-2-nitroethylene synthesis method

A technology of nitroethylene and synthesis method, which is applied in the chemical synthesis of 1-methylamino-1-methylthio-2-nitroethylene and the intermediate field of synthetic peptic ulcer drug ranitidine, which can solve complex problems. , product quality decline, many by-products, etc., to achieve the effect of reducing unit operations and equipment, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below.

[0048] A synthetic method of 1-methylamino-1-methylthio-2-nitroethylene, comprising the following steps:

[0049] (1) Preparation of Potassium Hydroxide Ethanolic Solution

[0050] Add 190kg KOH and 400kg absolute ethanol into a 1000 liter enamel or stainless steel reaction kettle for alkali dissolution, heat to 40-80°C under stirring to dissolve, and cool down to room temperature for use after complete dissolution.

[0051] (2) Preparation of 1,1-dipotassium thio-2-nitroethylene

[0052] Add 150kg of nitromethane, 170kg of carbon disulfide and 150kg of absolute ethanol to a 2000-liter enamel or stainless steel addition reaction kettle, and start adding potassium hydroxide ethanol solution dropwise at 20°C under stirring. hours, then cooled down to below room temperature, and filtered to obtain brick red solid 1,1-dipotassium thio-2-nitroethylene, and the filtrate ethanol was recovered and recycled.

[0053] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com