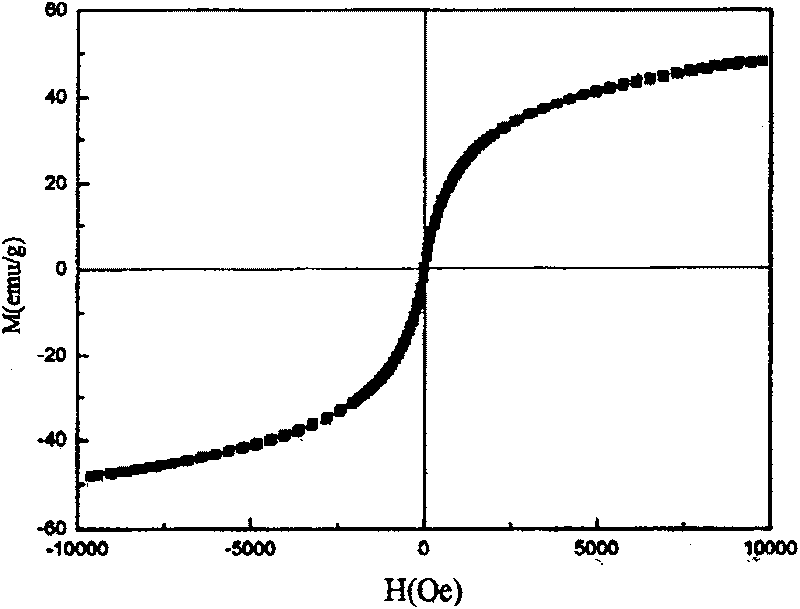

Superparamagnetic zinc ferrite nanomaterial and its preparation method

A nano-material, zinc ferrite technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of large particle size and difficult size control of nano-zinc ferrite, and achieve particle size The effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

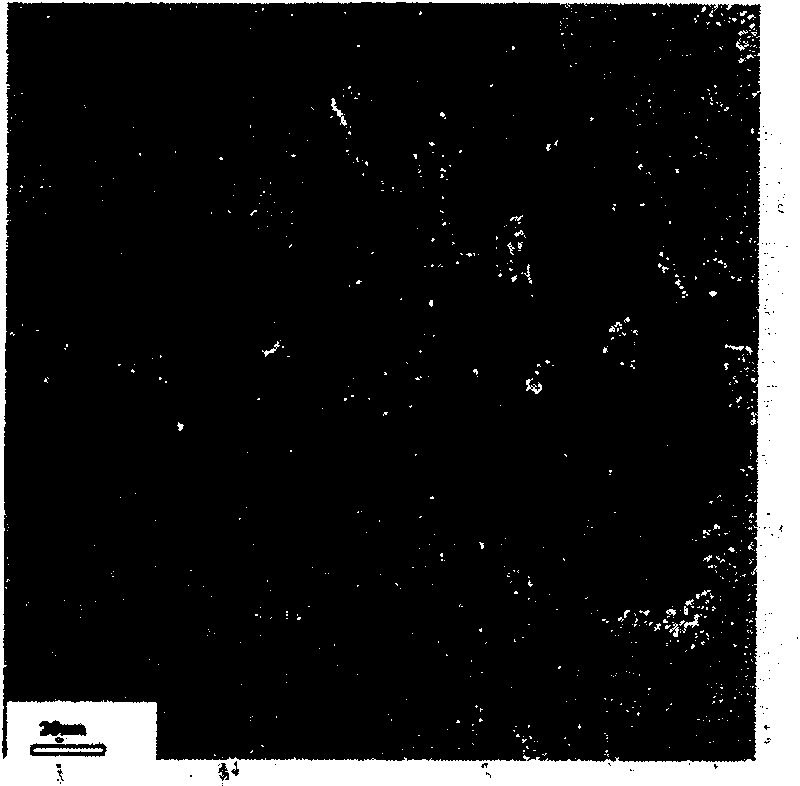

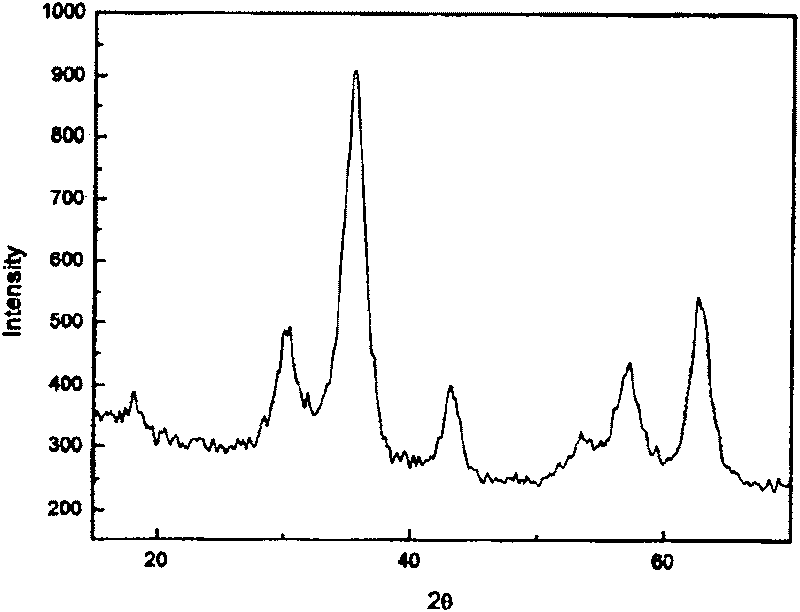

[0030] Embodiment 1: After 2.8227 gram of AOT is dissolved in 64ml n-heptane, put into the 250ml four mouthfuls of round-bottomed reaction flasks (fitting condensing reflux pipe) that is equipped with mechanical stir bar, and protected by nitrogen atmosphere; pH value is 2, FeCl 3 , FeSO 4 , ZnSO 4 Concentrations are 0.57mol L -1, 0.2mol·L -1 , 0.09mol·L -1 1.7ml of the mixed solution was added to the above solution and stirred for more than half an hour, and 3mol·L -1 NaOH was dropped into the microemulsion of iron salt which was stirred vigorously and the pH value was adjusted to 11; the color gradually turned brown and finally became dark black. The stirring reaction was continued for 10 minutes, and the reaction was continued for 30 minutes by heating in a water bath at 90°C. After the reaction was completed and cooled to room temperature, it was centrifuged at 10,000 rpm for 5 minutes, and washed three times with absolute ethanol and deionized water. Finally, the o...

Embodiment 2

[0031] Embodiment 2: After 5.6454 gram of AOT is dissolved in 64ml hexanaphthene, put into the 250ml four mouthfuls of round-bottomed reaction flasks that are equipped with mechanical stirrer (fit condensing reflux pipe), and be protected by nitrogen atmosphere; The pH value is 3, FeCl 3 , FeSO 4 , ZnSO 4 Concentrations are 0.6mol L -1 , 0.27mol L -1 , 0.03mol·L -1 1.7ml of the mixed solution was added to the above solution and stirred for more than half an hour, and 6mol·L -1 NaOH was dropped into the ferric salt microemulsion which was stirred vigorously and the pH value was adjusted to 13; the color gradually turned brown and finally became dark black. The stirring reaction was continued for 10 minutes, and the reaction was continued for 50 minutes by heating in a water bath at 60°C. After the reaction was completed and cooled to room temperature, it was centrifuged at 10,000 rpm for 5 minutes, and washed three times with absolute ethanol and deionized water. Finally...

Embodiment 3

[0032] Embodiment 3: after 2.8227 gram of AOTs are dissolved in 64ml decane, put into the 250ml four mouthfuls of round-bottomed reaction bottles that are equipped with mechanical stirrer (fit condensing reflux tube), and be protected by nitrogen atmosphere; pH is 2, Fe 3+ , Fe 2+ , Zn 2+ 0.57mol L -1 , 0.2mol·L -1 , 0.09mol·L -1 4.0ml of the mixed solution was added to the above solution and stirred for more than half an hour, and 5mol·L -1 NaOH was dropped into the microemulsion of iron salt which was stirred vigorously and the pH value was adjusted to 11; the color gradually turned brown and finally became dark black. The stirring reaction was continued for 10 minutes, and the reaction was continued for 30 minutes by heating in a water bath at 80°C. After the reaction, it was aged for one hour, cooled to room temperature under the protection of nitrogen atmosphere, centrifuged at 10,000 rpm for 5 minutes, and washed three times with absolute ethanol and deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com