Lysozyme-chitosan films

A technology of chitosan and lysozyme, which can be used in food preservation, cheese substitutes, fruit and vegetable preservation, etc., and can solve the problems of limited application of antibacterial efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Material

[0048] Shrimp chitosan from Vanson Inc. (Redmond, WA) was used without further purification. Shrimp chitosan was characterized by a viscosity of 11 cps in 1% w / w aqueous acetic acid at 25°C and a deacetylation of 89.9%. Egg white lysozyme was obtained from Eiprodukte GmbH und Co. (Germany). USP (United States Pharmacopeia) grade glycerol was obtained from EM Science (Darmstadt, Germany). Reagent grade glacial acetic acid was obtained from J.T. Baker (Phillipsburg, NJ).

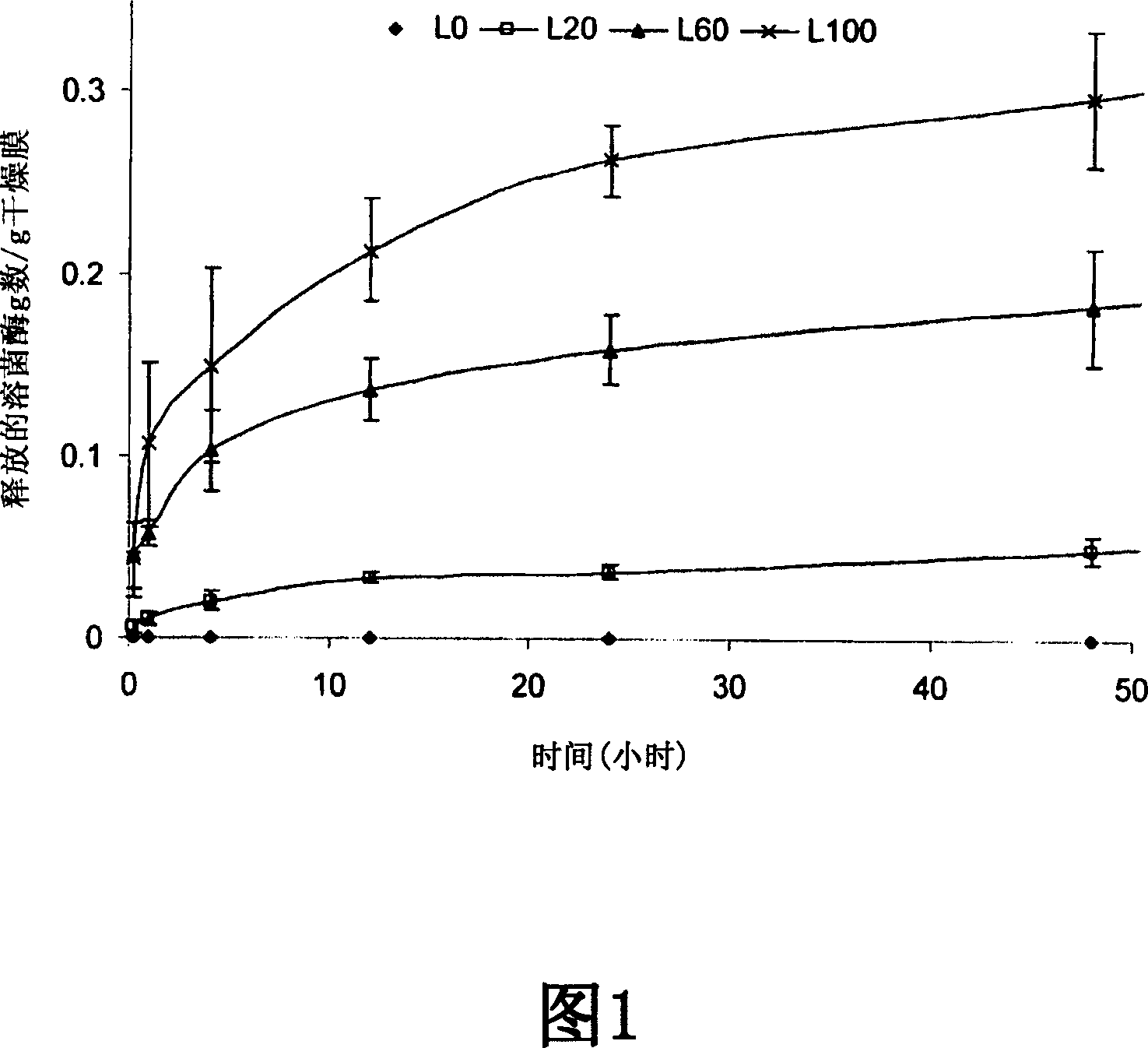

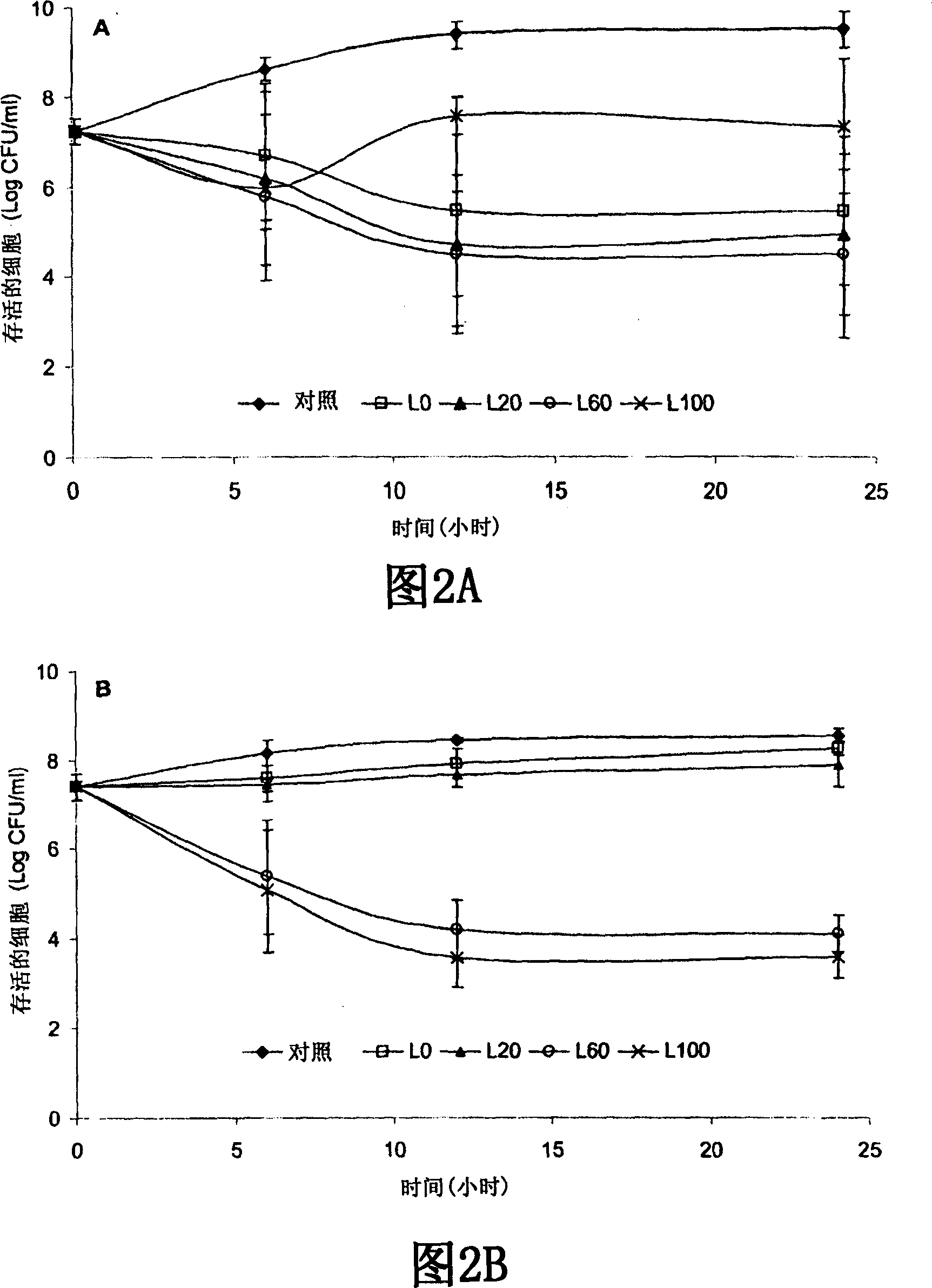

[0049] Gram-positive Streptococcus faecalis ATCC 14508 and Gram-negative Escherichia coli type B were used as test organisms. Freeze-dried Micrococcus lysodeikticus obtained from Sigma Chem. Co. (St. Louis, MO) was used for the measurement of lysozyme release profile. Brain heat infusion (BHI), MRS broth and agar were purchased from Difcoof Becton, Dickinson and Company (Sparks, MD).

[0050] Preparation of film-forming solution

[0051] A film-forming solution (FFS) was prepared by mix...

Embodiment 2

[0104] Selective FFS can be achieved by dissolving 2 wt% chitosan in 1 wt% acetic acid solution supplemented with 50 wt% dodecanoic acid, 25 wt% glycerol and 100 wt% lysozyme (w / w chitosan) at 65°C to prepare. Membranes were then prepared as described in Example 1. Addition of fatty acids (ie, dodecanoic acid) to the film-forming solution improved the water resistance of the film without significantly affecting its antimicrobial activity.

Embodiment 3

[0106] A coating solution was prepared by mixing a chitosan solution with a lysozyme solution. A chitosan solution was prepared by dissolving 3% chitosan in a 1% acetic acid solution supplemented with 25% glycerol (w / w chitosan). A lysozyme solution was prepared by dissolving 10% lysozyme in distilled water supplemented with 25% glycerol (w / w lysozyme). The lysozyme solution was mixed into the chitosan solution to a concentration of 60% (percent dry weight of lysozyme per dry weight of chitosan). The resulting mixture was homogenized using a homogenizer (PT 10-35, Kinematica, Switzerland) at 3,000 rpm for 60 seconds. Listeria monocytogenes ATCC 15313 and Lactobacillus plantarum were used as test microorganisms to evaluate the antimicrobial efficacy of coating treatments on food surfaces. Listeria monocytogenes and Lactobacillus plantarum were cultured overnight at 37°C in brain heart infusion (BHI) and MRS broth, respectively.

[0107] Commercially produced beef franks (Bun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com