Method for separating and purifying shikimic acid

A shikimic acid and residue technology, applied in the field of natural product chemistry, can solve the problems of limited resources of star anise, and achieve the effects of energy saving, less solvent consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

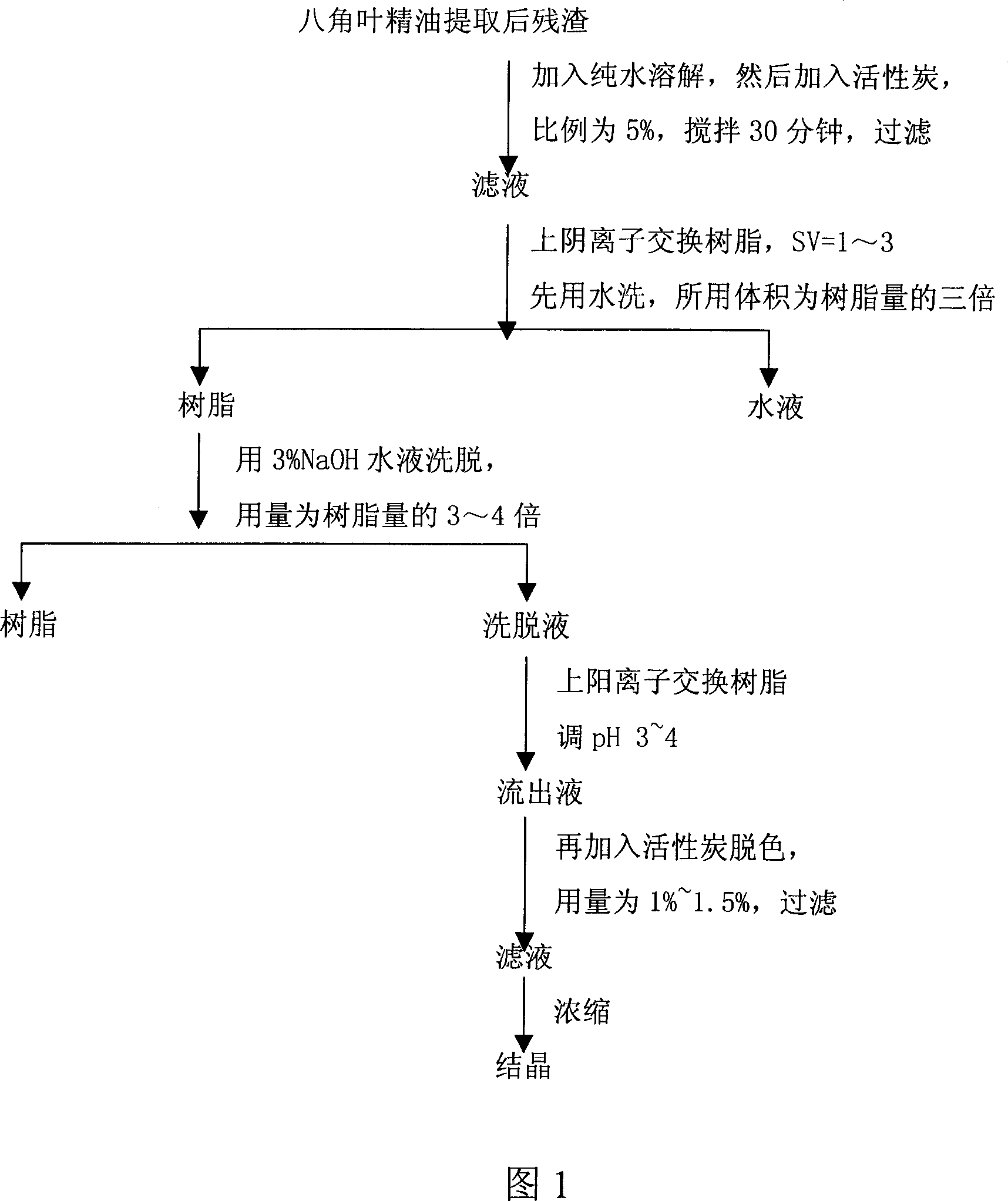

Method used

Image

Examples

Embodiment 1

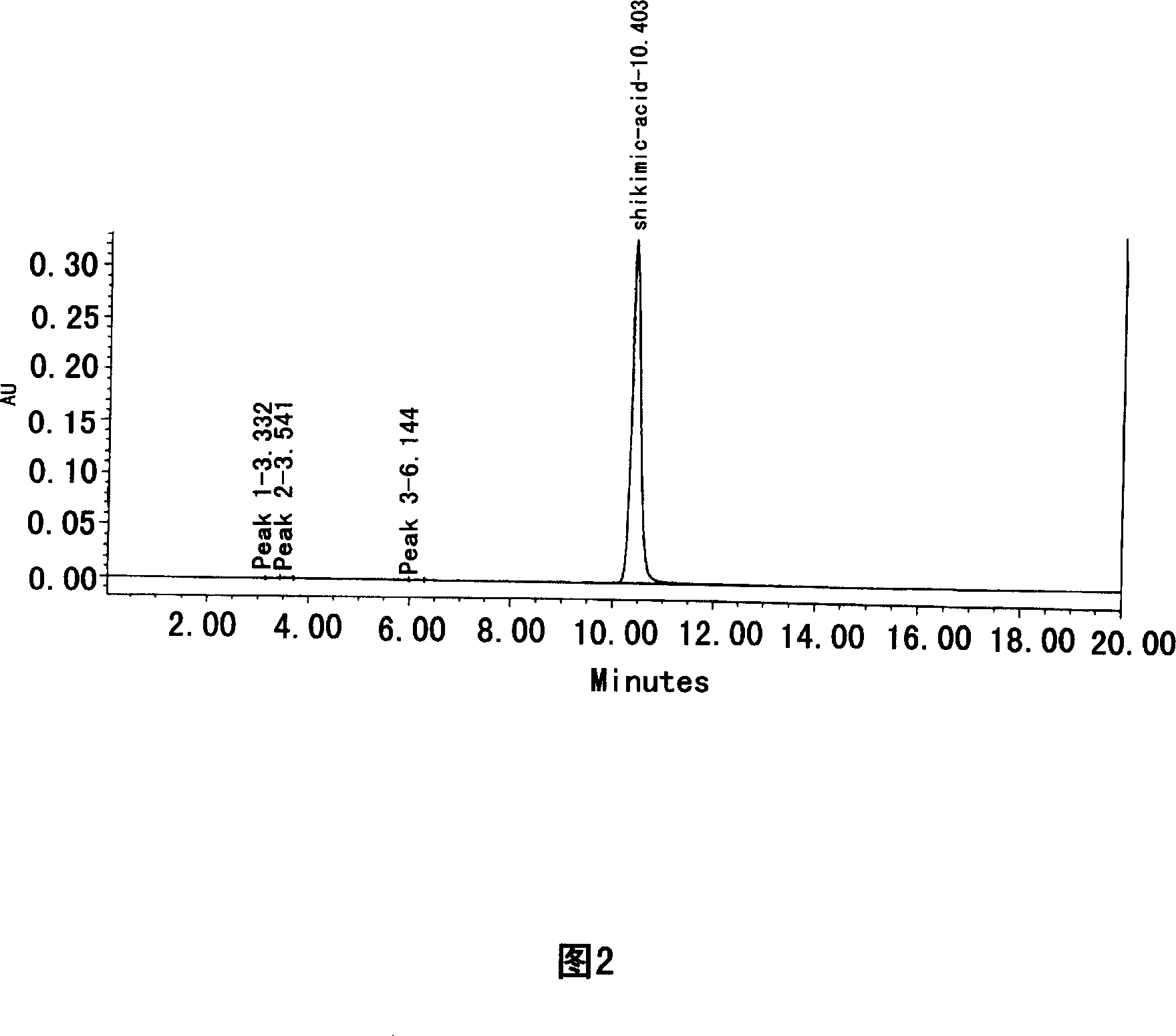

[0022] Dissolve 100g of residue after extraction of star anise leaf essential oil (the content of shikimic acid is 12% after detection), dissolve in 200ml of pure water, add 5g of activated carbon (Qingdao Ocean Chemical Factory), stir at room temperature to 45°C for 30min, and filter to obtain decolorization solution. Pack the column with 500ml of 717 strong basic styrene series (Shanghai Huizhi), and treat it with 3% NaOH solution to form an OH type resin column. The above-mentioned decolorizing solution is processed through the OH type anion exchange resin column to absorb shikimic acid. Wash with 1000ml of pure water, and then elute with 1500ml of 3% NaOH to obtain the site containing shikimic acid. The site was passed through 500ml of H-type strongly acidic cation exchange resin (732 strongly acidic styrene series, Shanghai Huizhi) to remove sodium ions. The resulting solution was concentrated. Static crystallization at 0-4°C gave shikimic acid (9.7g, 98.5%).

[0023] ...

Embodiment 2

[0025] Dissolve 1000g of the residue after extraction of star anise leaf essential oil (the content of shikimic acid is 10% after detection), dissolve in 2000ml of pure water, add 50g of activated carbon (Wako Pure Chemical Industries, Ltd.), stir at room temperature to 45°C for 30min, and filter to obtain a decolorizing solution. Pack the column with 5000ml of 717 strong basic styrene series (Shanghai Huizhi), and treat it with 5% NaOH solution to form an OH type resin column. The above-mentioned decolorizing solution is processed through the OH type anion exchange resin column to absorb shikimic acid. Wash with 10,000 ml of pure water, and then elute with 15,000 ml of 5% NaOH to obtain the site containing shikimic acid. The site was passed through 5000ml of H-type strongly acidic cation exchange resin (732 strongly acidic styrene series, Shanghai Huizhi) to remove sodium ions. The resulting solution was concentrated. Static crystallization at 0-4°C gave shikimic acid (88.5...

Embodiment 3

[0027] Dissolve 1000g of the residue after extraction of star anise leaf essential oil (the content of shikimic acid is 10% after detection), dissolve in 2000ml of pure water, add 50g of activated carbon (Wako Pure Chemical Industries, Ltd.), stir at room temperature to 45°C for 30min, and filter to obtain the decolorizing solution. Pack the column with 5000ml of 717 strong basic styrene system (Shanghai Huizhi), and treat it with 10% NaOH solution to form an OH type resin column. The above-mentioned decolorizing solution is processed through the OH type anion exchange resin column to absorb shikimic acid. Wash with 10,000 ml of pure water, and then elute with 15,000 ml of 10% NaOH to obtain the site containing shikimic acid. The site was passed through 5000ml of H-type strongly acidic cation exchange resin (732 strongly acidic styrene series, Shanghai Huizhi) to remove sodium ions. The resulting solution was concentrated. Static crystallization at 0 ~ 4 ℃ to obtain shikimic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com