Surface grafting organic functional molecular nano silicon dioxide, and its preparing method

A technology of nano-silica and surface grafting, which is applied in the treatment of dyed low-molecular organic compounds, etc., can solve the problems of poor extraction resistance, easy migration, and easy loss, etc., and achieve the solution of extraction resistance and improve the overall performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

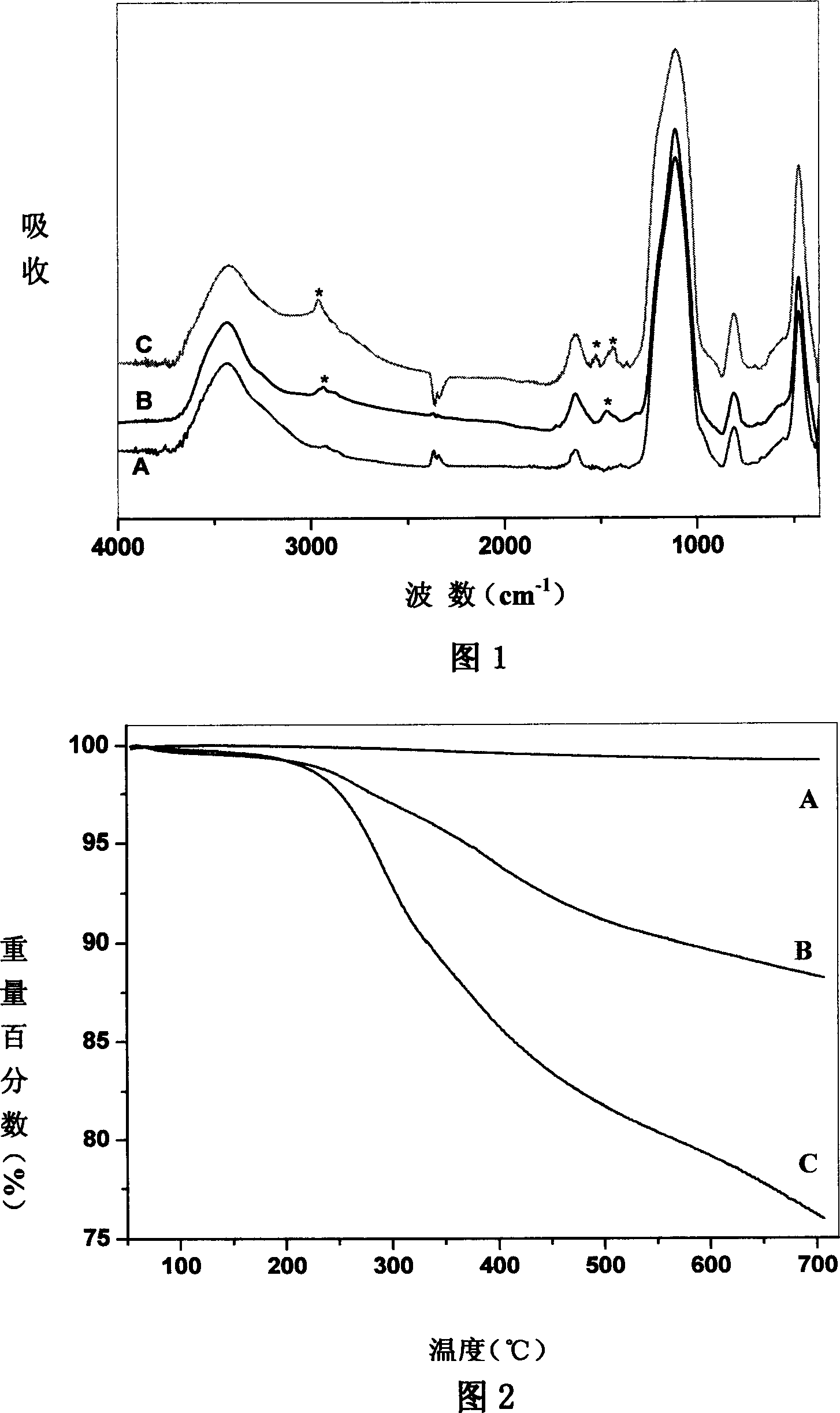

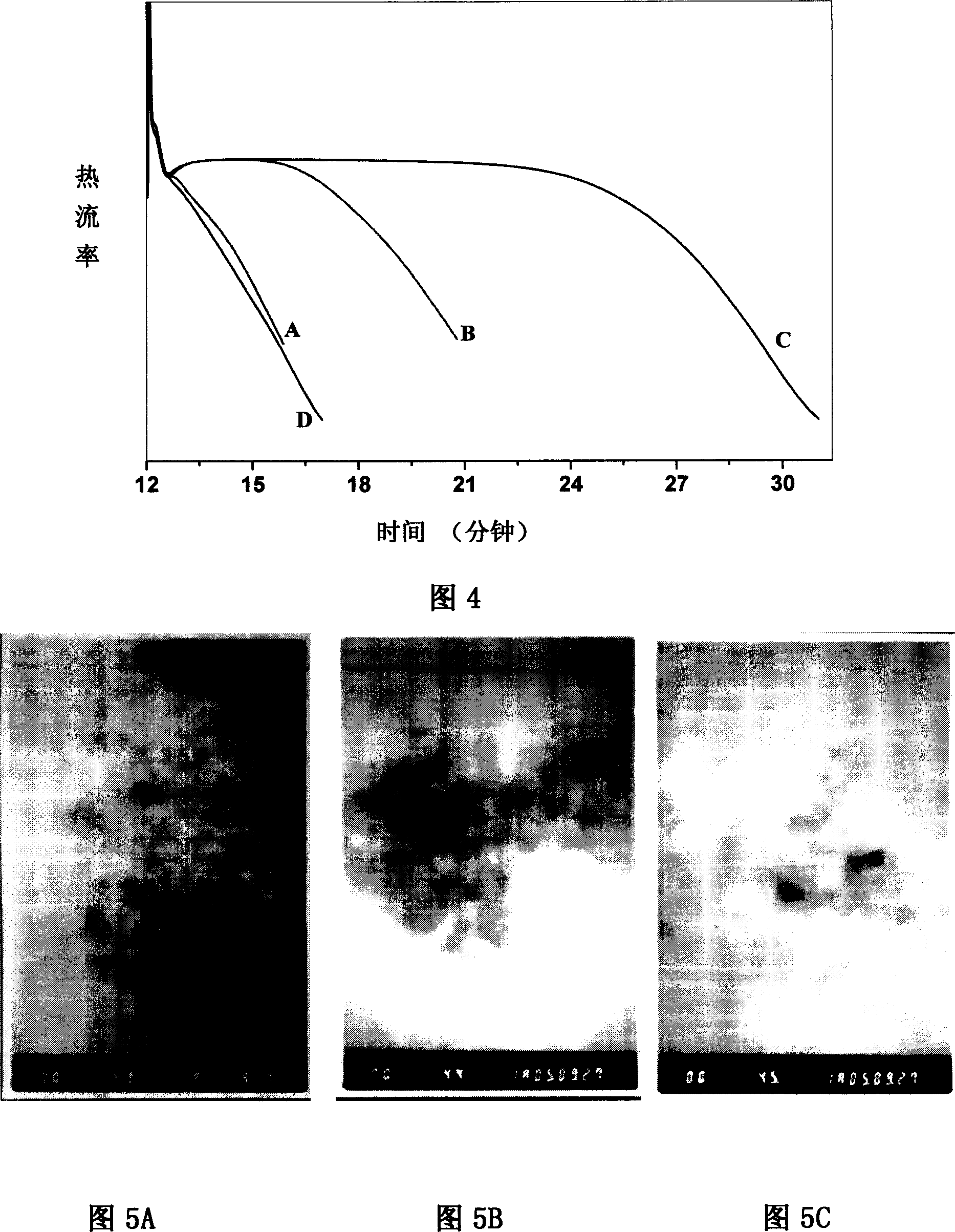

[0039] Example 1: The nano-silica used in the present invention is Degussa A-200, which is prepared by a gas phase method, with a primary particle size of 12nm and a specific surface area of 200 ± 25m 2 / g. The surface contains hydroxyl groups and unsaturated residual bonds, and has strong hydrophilicity.

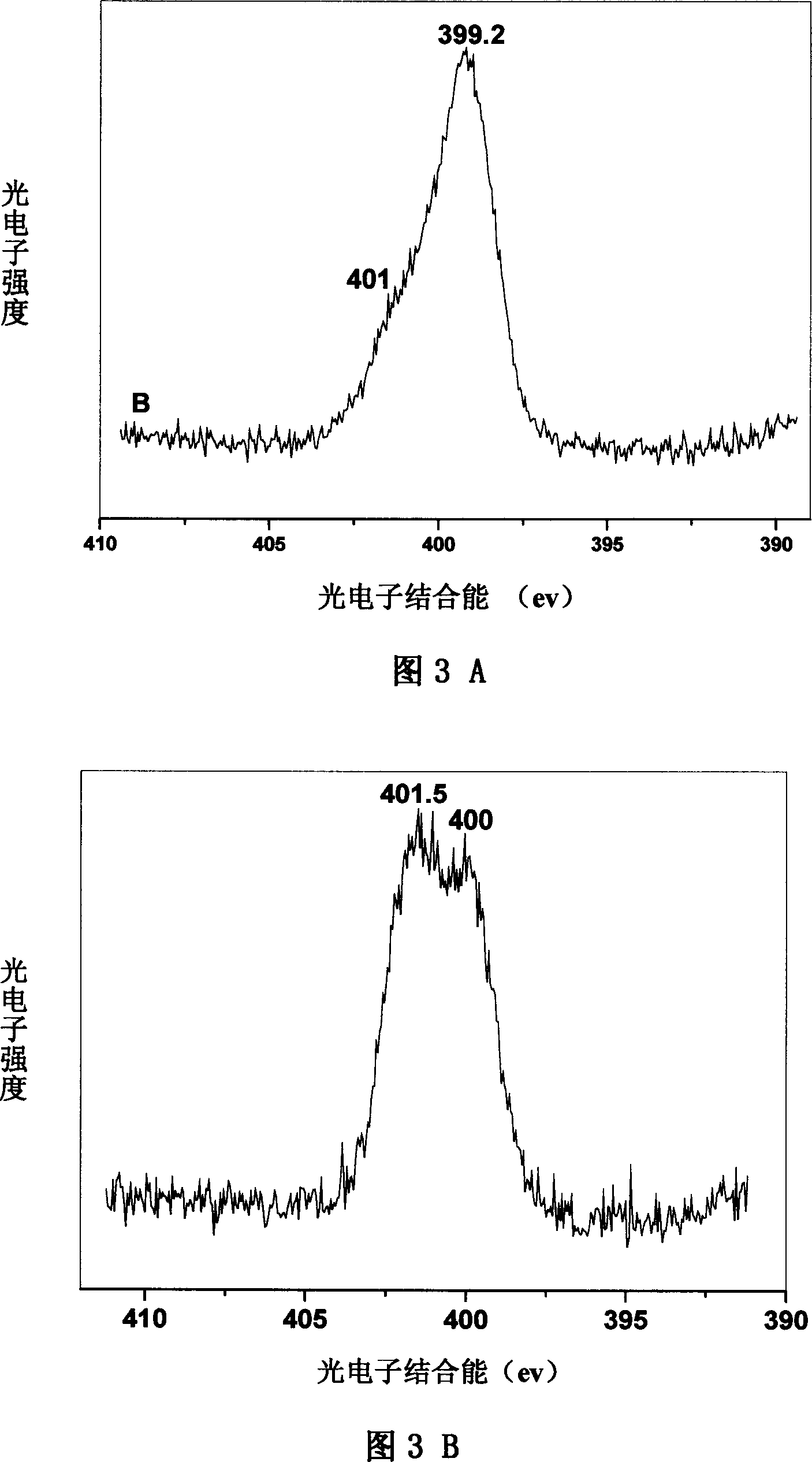

[0040] Aminosilane coupling agent chemical grafting treatment of nano-silica: Weigh 3g of nano-silica (A-200) and disperse in about 150ml toluene, stir to form a stable suspension; then add 3.9g N-(β- Aminoethyl)-γ-aminopropyltrimethoxysilane, the mixture was stirred and reacted at 100-110°C for 24 hours, then filtered, and the filtrate was washed three times with toluene and ethanol, and the amount of solvent used for each washing was 150ml. Put the washed nano silicon dioxide into a vacuum oven at 100° C. for 6 hours.

[0041] Antioxidant molecular acyl chloride: Weigh 0.5 g of hindered phenol antioxidant 3,5-di-tert-butyl-4-hydroxyl-phenylacrylic acid, add it to abou...

Embodiment 2

[0044] With embodiment 1, wherein nano-silica surface is processed with aminosilane coupling agent N-(β-aminoethyl)-γ-aminopropyltriethoxysilane, the acyl chloride of antioxidant molecule and antioxidant The same method as in Example 1 was used for the grafting of molecules onto the nano-silica treated with the coupling agent.

Embodiment 3

[0046] With embodiment 1, wherein the surface of nano silicon dioxide is processed with 4.5g aminosilane coupling agent γ-aminopropyltriethoxysilane, the acyl chlorination of antioxidant molecule and the grafting of antioxidant molecule to coupling agent treatment The same method as in Example 1 is adopted on the nano-silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com