Flame-retardant epoxy resin composition

一种环氧树脂、组合物的技术,应用在运输和包装、印刷电路、薄料处理等方向,能够解决无法表现出阻燃性等问题,达到优异耐热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation of component (A) can also be carried out in the presence of a suitable solvent capable of dissolving component (A). If a solvent is used, preferred examples include inert solvents such as N,N-dimethylformamide, N,N-diethylformamide, N-methyl-2-pyrrolidone, dimethylsulfoxide, methylethyl Ketones, xylene, toluene, methyl cellosolve, tetrahydrofuran, etc. These solvents may be used alone or in combination of two or more.

[0047] In the preparation of component (A), a predetermined amount of epoxy resin raw material is charged into a reaction vessel, and then the reaction vessel is heated and adjusted at a prescribed temperature. Next, the catalyst is added mixed with water or a suitable solvent. The addition of the catalyst is carried out at a temperature ranging from 20°C to 200°C, preferably at 80°C to 200°C, more preferably at 110°C to 180°C. It is preferable to add the catalyst at a temperature greater than or equal to 20°C, because the reaction bet...

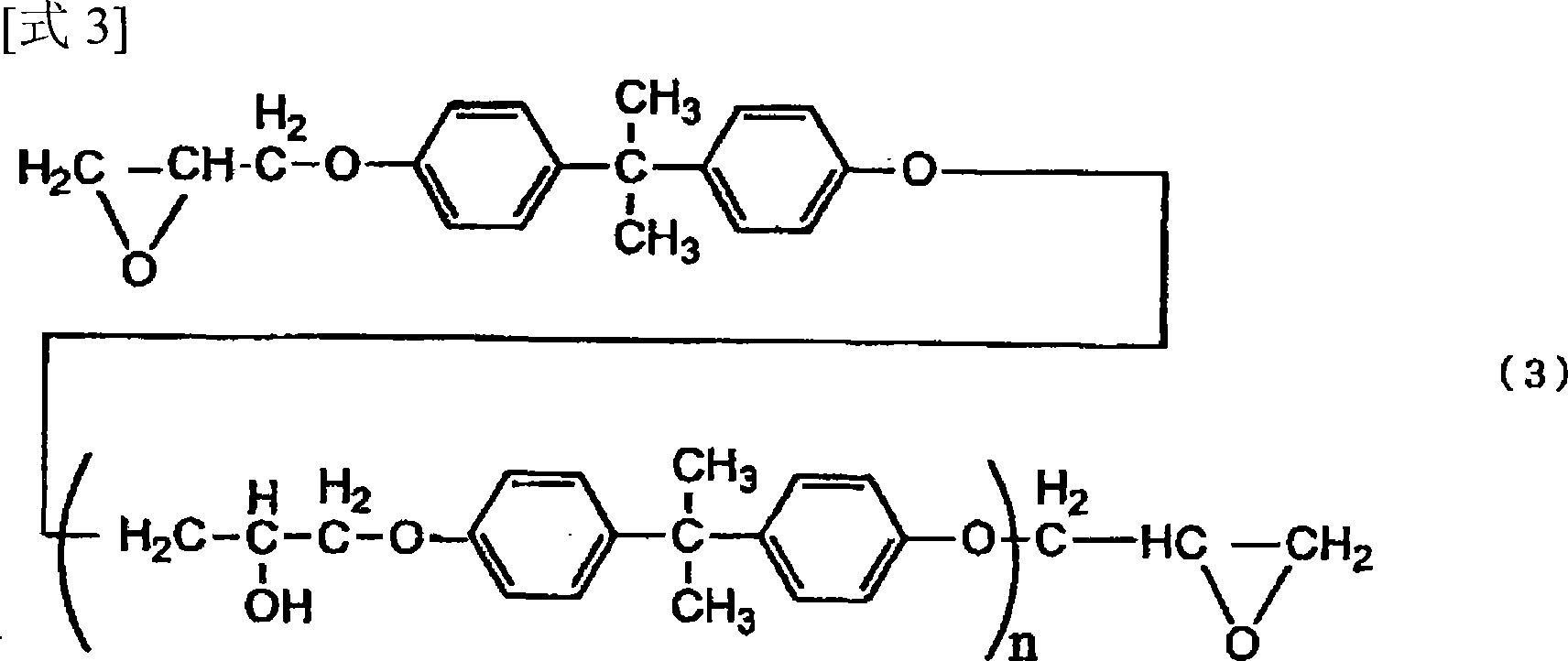

preparation example 1

[0095] 0.04 parts of tetrabutylammonium bromide were added to 100 parts of bisphenol A epoxy resin (epoxy equivalent: 189 g / equivalent). The resulting solution was heated with stirring to an internal temperature of 175°C. To this solution was added 16.1 parts of Coronate T-80 over a period of 120 minutes TM (TDI, manufactured by Nippon Polyurethane Industry Co., Ltd.; approximately 80% of 2,4-toluene diisocyanate, approximately 20% of 2,6-toluene diisocyanate). Immediately after the addition was complete, the resulting solution was stirred for 4 hours while maintaining the reaction temperature at 175° C., thereby obtaining epoxy resin I containing an oxazolidinone ring.

preparation example 2

[0097] 0.04 parts of tetrabutylammonium bromide were added to 100 parts of bisphenol A epoxy resin (epoxy equivalent: 189 g / equivalent). The resulting solution was heated with stirring to an internal temperature of 175°C. To this solution was added 30.9 parts of MR-200 over a period of 120 minutes TM (diphenylmethane diisocyanate manufactured by Nippon Polyurethane Industry Co., Ltd.). Immediately after the addition was complete, the resulting solution was stirred for 4 hours while maintaining the reaction temperature at 175° C., thereby obtaining epoxy resin II containing an oxazolidinone ring.

[0098] The properties of epoxy resins I and II containing oxazolidinone rings are shown in Table 1. In Table 1, "n=0 component" means an unreacted monomer component in the bisphenol A type epoxy resin raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com