Bearing constituent member, method of manufacturing bearing constituent member, and rolling bearing

a constituent member and bearing technology, applied in the field can solve the problems of increasing the manufacturing cost of bearing constituent members, increasing the number of processes, and increasing the toughness, and achieve the effect of long life and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

;

[0030]FIG. 15 is a graph showing the results of investigating a relationship between surface Vickers hardness and the foreign material-in-oil lifetime (L10 lifetime) regarding Test Example 1;

[0031]FIG. 16 is a table showing steel which is used in each of Examples 1 to 5 and Comparative Examples 1 to 5;

[0032]FIG. 17 is a table showing the heat treatment conditions of Examples 1 to 5 and Comparative Examples 1 to 5;

[0033]FIG. 18 is a table showing conditions of a rolling fatigue test;

[0034]FIG. 19 is a table showing the results of Test Example 1; and

[0035]FIG. 20 is a diagram showing heat treatment conditions in a case where SNCM steel is used as a raw material during the manufacturing of a bearing constituent member of the related art.

DETAILED DESCRIPTION OF EMBODIMENTS

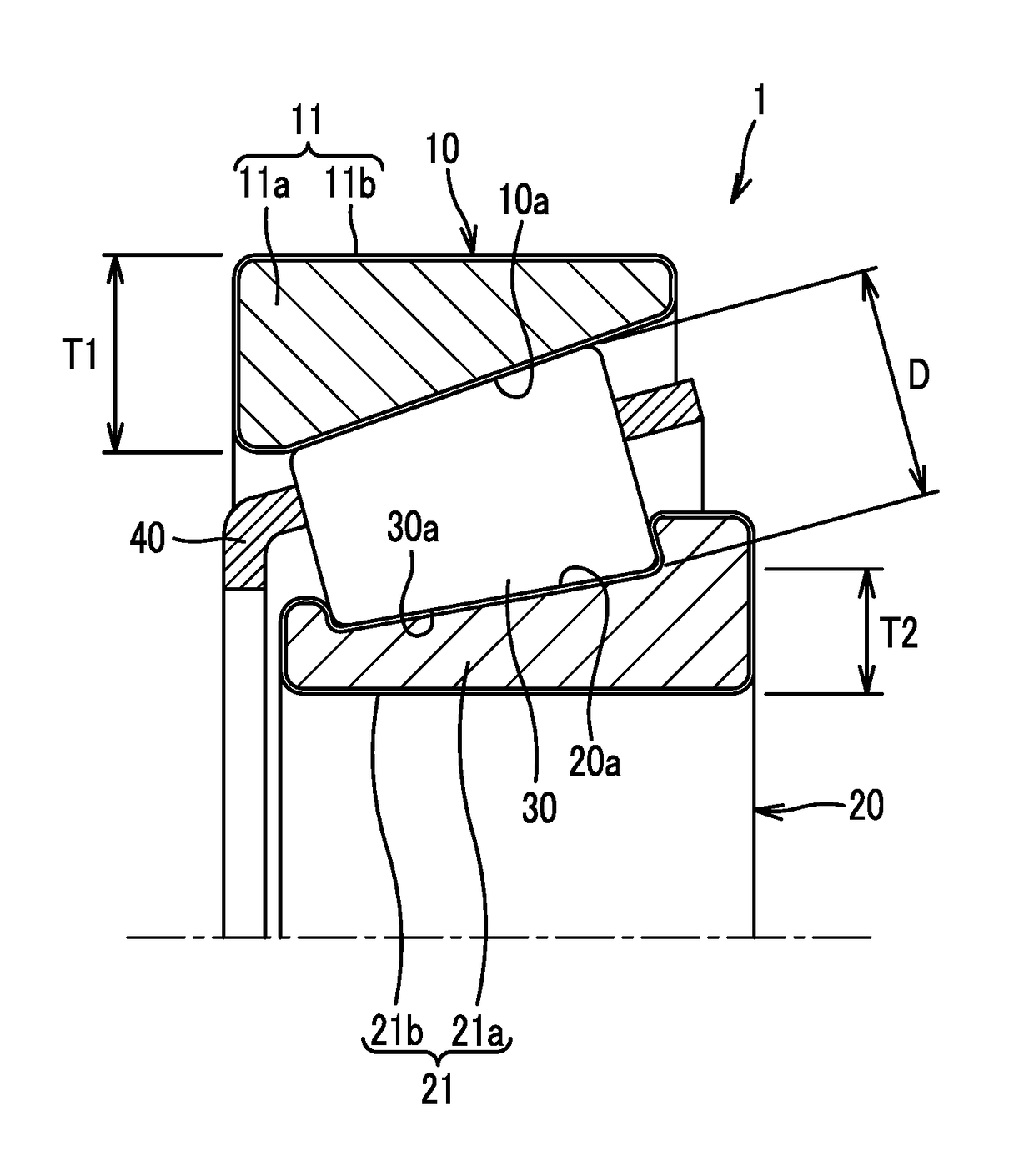

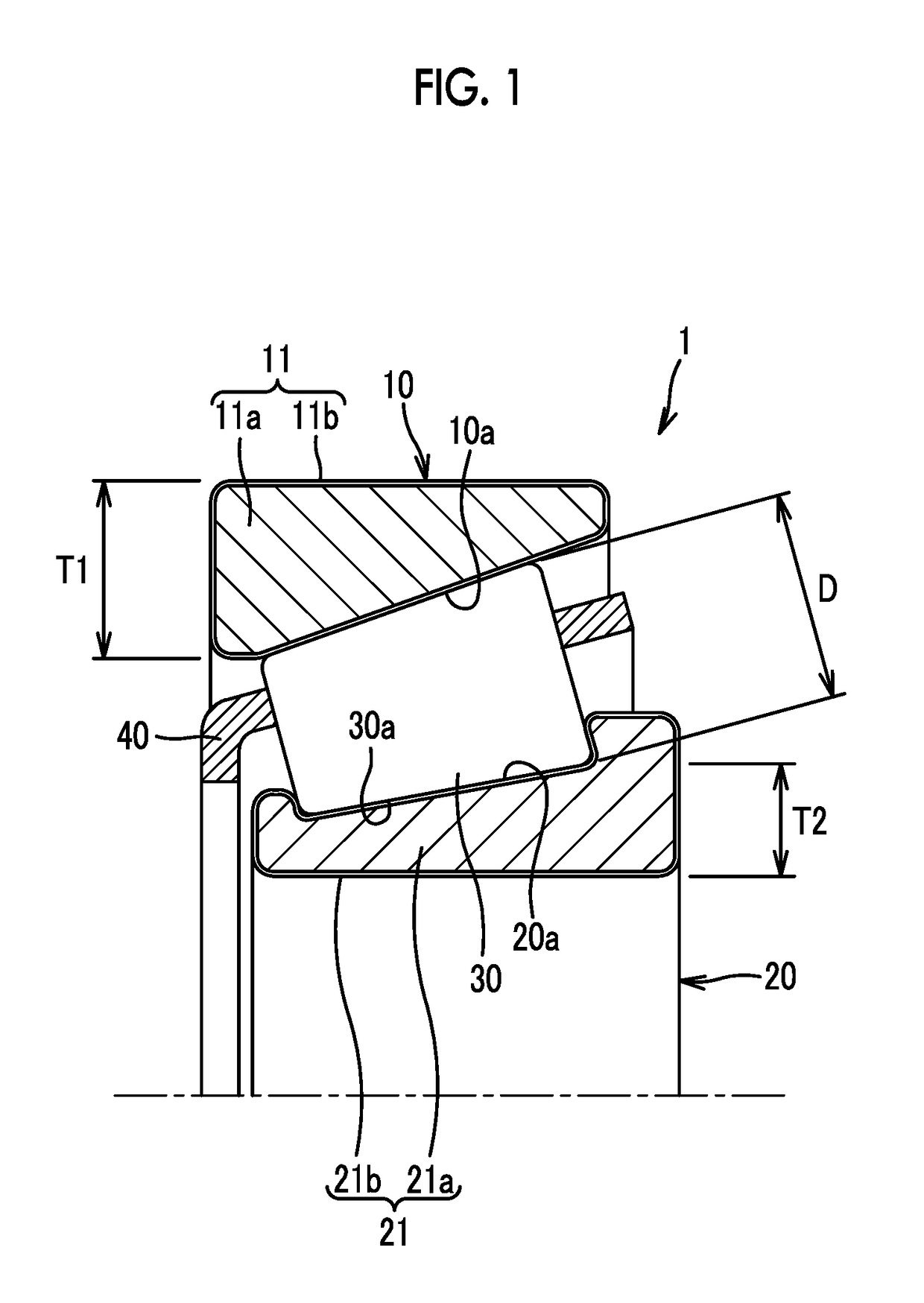

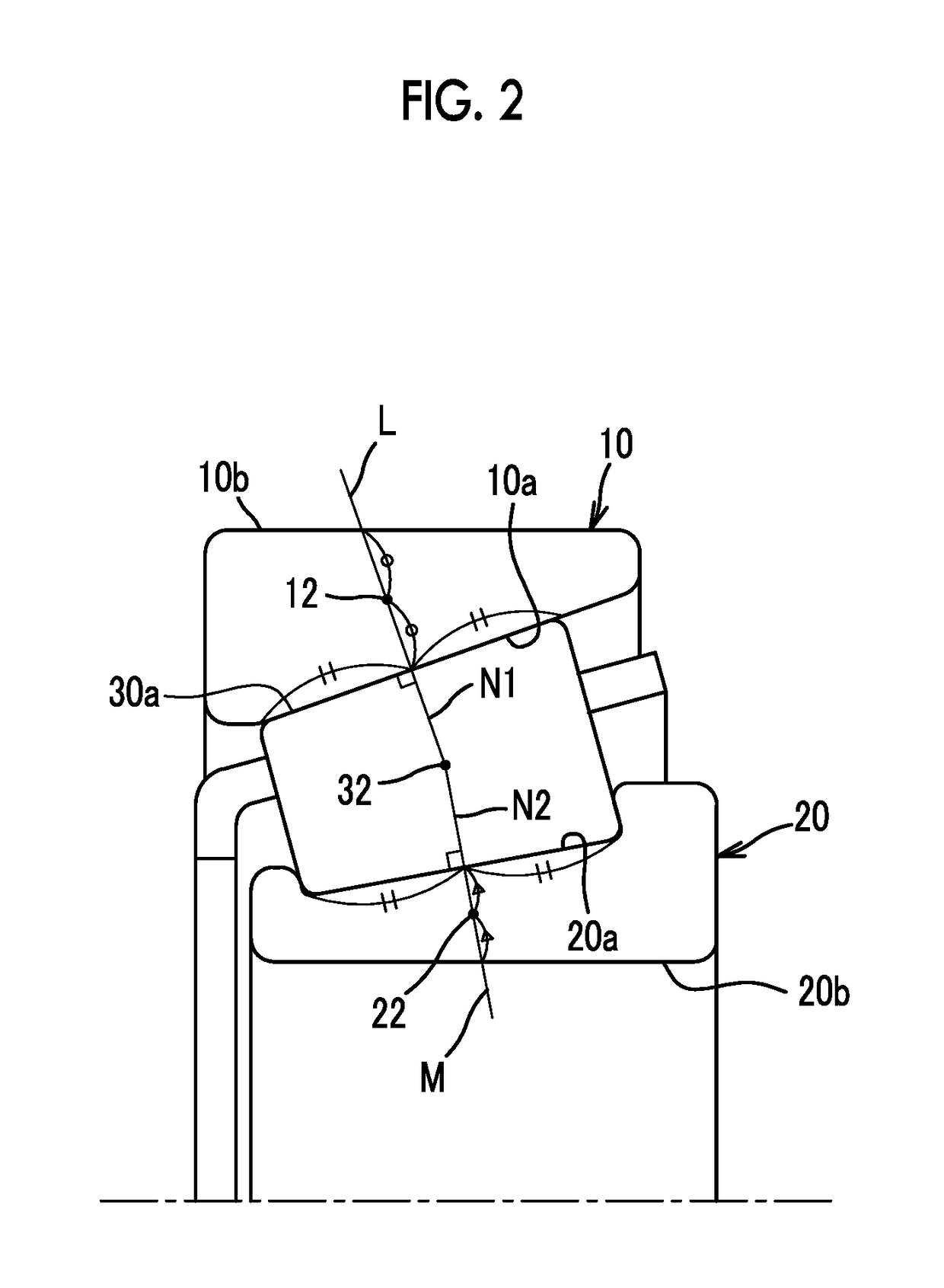

[0036]Hereinafter, a rolling bearing and a bearing constituent member according to an embodiment of the invention will be described using the accompanying drawings. Hereinafter, a case where each of an outer ring and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com