Apparatus and method for processing a substrate

a substrate surface and apparatus technology, applied in the direction of non-linear optics, cleaning using liquids, instruments, etc., can solve the problems of inability to produce active oxygen in the vicinity of the substrate surface, and inability to decompose ultraviolet light rays. , to achieve the effect of reducing the capacity of activating organic substances on the substrate surface, reducing the capacity of substrate surface activation, and reducing the capacity of substrate surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

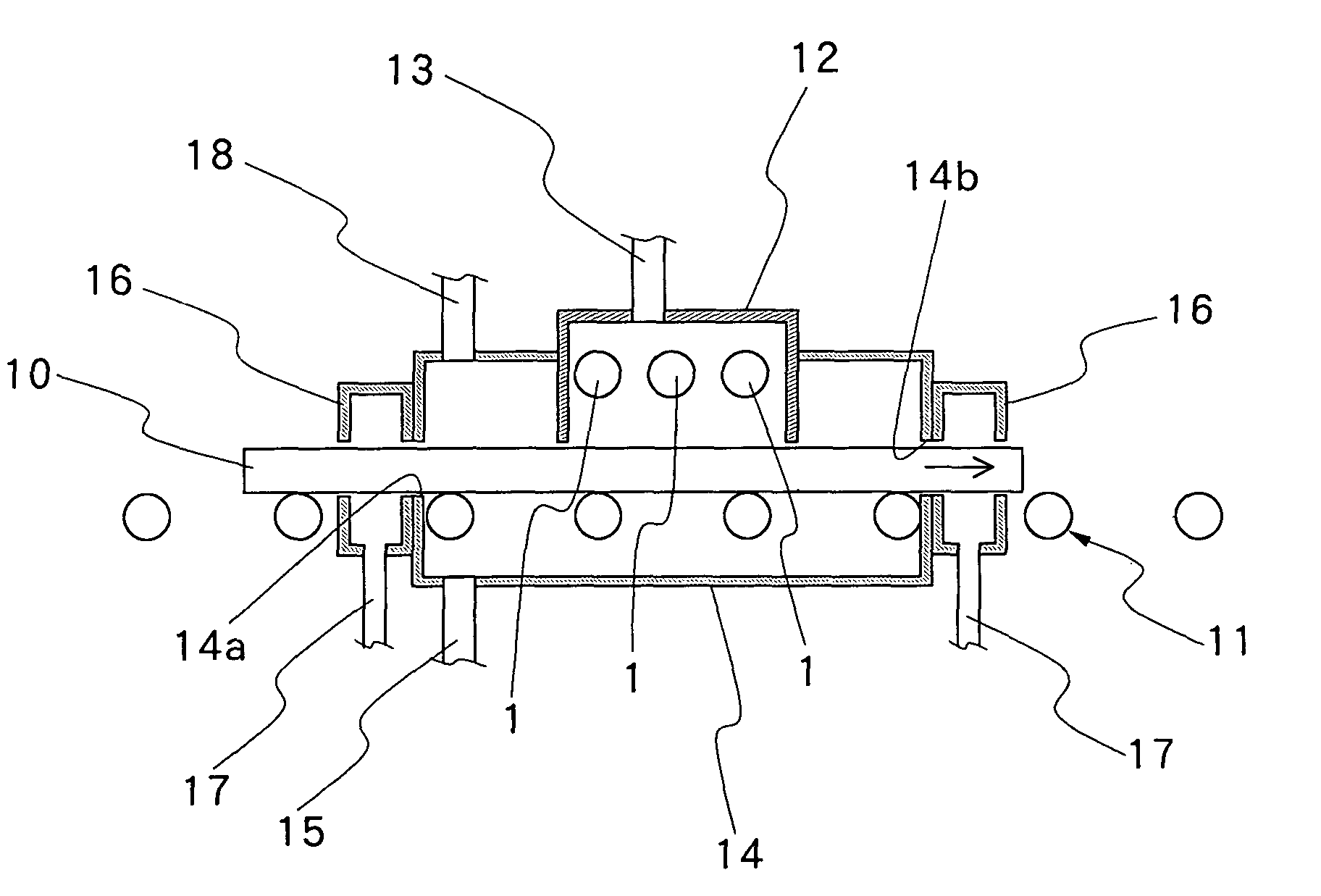

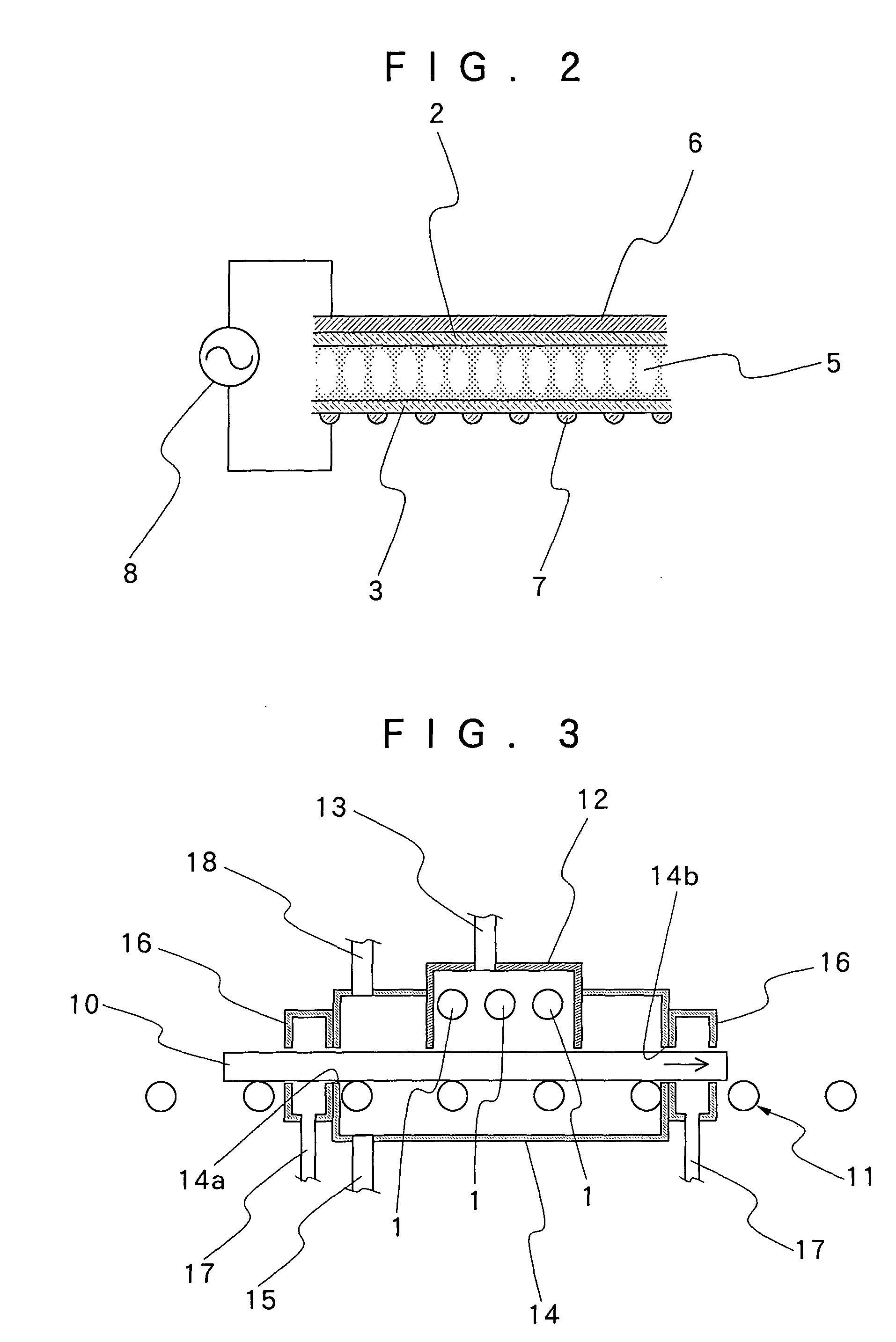

first embodiment

[0046] In the case of the first embodiment described above, the lamp house is connected to the lower chamber. However, for the sake of simplification in construction, it may be arranged, for example, as shown in FIG. 5. In the embodiment of FIG. 5, a lamp house 112 is arranged to completely cover or enshroud discharge lamps 1. In this case, on the side which faces a substrate 10, the lamp house 112 is provided is with a window 112a which is fitted with a pane of glass which is highly transmissive of ultraviolet light, such as synthetic quartz glass or the like. With the lamp house 112 of this construction, the inert gas is sealed in the lamp house 112 and not allowed to escape to the outside. Accordingly, in this case, there is no necessity for constantly feeding an inert gas to the lamp house 112 as long as a predetermined amount of inert gas is sealed therein.

[0047] Shown in FIG. 6 are results of wettability improving experiments using the apparatus of FIG. 5 and changing the natu...

fourth embodiment

[0057] Illustrated in FIG. 8 is the present invention. In this embodiment, a boundary is provided across an opening at the lower end of the lamp house 212 which is projected into the chamber 214, drawing a border between a dry nitrogen gas atmosphere in the lamp house 212 and a moistened inert gas atmosphere in the chamber 214. The boundary is formed by the use of a partition plate 202 of a predetermined thickness. The partition plate 202 is constituted, for example, by a plate of honeycomb or grid-like structure which contains a multitude of fine passages across its thickness and in its entire surface areas. Further, the partition plate is coated with a reflecting film, including inner surfaces of fine passages.

[0058] In this case, the dry nitrogen gas in the lamp house 212 is maintained at a pressure level slightly higher than a gas pressure within the chamber 214. Therefore, a border is defined between the dry nitrogen gas atmosphere in the lamp house 212 and the moistened inert ...

fifth embodiment

[0059] Furthermore, in place of the above-described partition plate, a window pane 202 of an ultraviolet light transmitting material such as quartz glass or the like may be fitted in the lower opening of the lamp house as in the invention shown in FIG. 9. In this case, although dry nitrogen gas is supplied to the lamp house 212 through a nitrogen gas feed pipe 213, there is no necessity for keeping the supply of dry nitrogen gas because the lamp house 212 is substantially in a closed state.

[0060] Any way, in the foregoing second to fifth embodiments, pressure chambers may be provided on the outer side of the entrance and exit openings 214a and 214b of the chamber 214 in the same manner as in the first embodiment. The exhaust pipe 218 is not required in case such pressure chambers are maintained at a negative pressure level.

[0061] Shown in FIG. 10 is a sixth embodiment of the present invention. In this embodiment, the processing apparatus is arranged to generate moistened inert gas w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength distribution | aaaaa | aaaaa |

| wavelength distribution | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com