Process of producing microcapsules and product thereof

a microcapsule and production process technology, applied in the field of making microcapsules, can solve the problems of poor batch-to-batch reproducibility, poor microcapsule generation efficiency, and poor quality of microcapsules, and achieve excellent high temperature resistance to premature release of encapsulated materials, good manufacturability, and excellent resistance to low pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 3

n)

[0112] The organic phase and aqueous phase (Versa TL 502 / TL130: 100 / 0) were mixed using a propeller mixer at 1000 rpm for 10 minutes at room temperature to form a premix. The premix was then passed through a homogenizer (Microfluidizer) once at a pressure greater than 6000 psi. The resultant mixture was heated in a 60° C. bath for 10 minutes before a melamine formaldehyde prepolymer solution was added. The prepolymer was formed by reacting 3.9 grams of melamine and 6.5 grams of 37% formaldehyde solution in 44 grams of water (pH>8). The pH was adjusted to pH 6 with H3PO4 and the reaction mixture was heated to 70 C for 2 hours while mixing at 1500 rpm. A solution of 2.5 grams of urea in 7 grams of water was then added to the reaction mixture and reaction was allowed to continue at 70° C. for 40 minutes. The stirring was adjusted to 500 rpm. The pH was adjusted to 9 using a 10% NaOH solution.

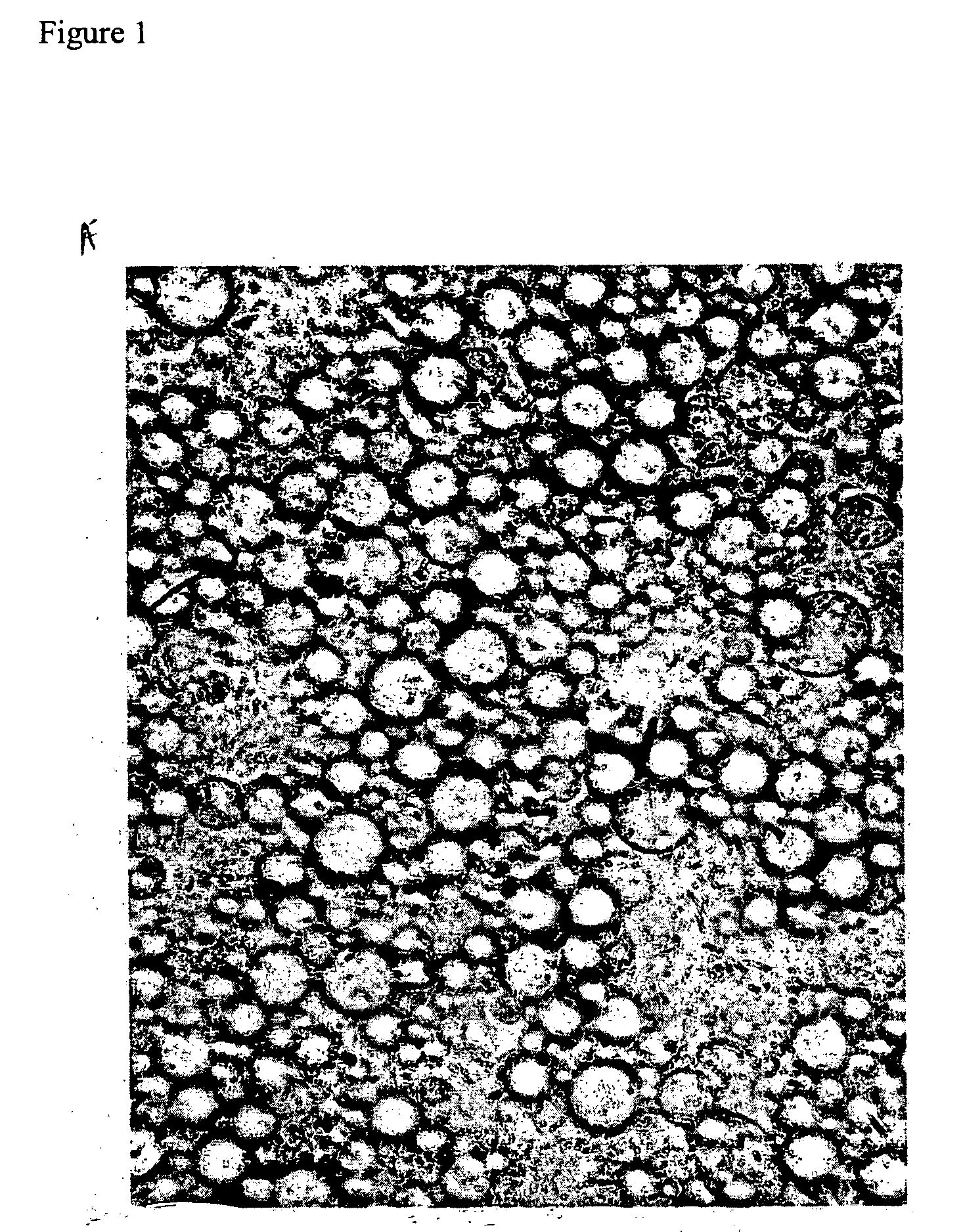

[0113] A drop of microcapsule solution was place on a cover glass and its photomicrograph wa...

example 4

n)

[0114] The organic phase and aqueous phase (Versa TL 502 / TL130: 30 / 70) were mixed using a propeller mixer at 1000 rpm for 10 minutes at room temperature to form a premix. The premix was then passed through a homogenizer once at a pressure greater than 6000 psi. The resultant mixture was heated in a 60° C. bath for 10 minutes before a melamine formaldehyde prepolymer solution was added. The prepolymer was formed by reacting 3.9 grams of melamine and 6.5 grams of 37% formaldehyde solution in 44 grams of water (pH>8). The pH was adjusted to pH 6 with H3PO4 and the reaction mixture was heated to 70 C for 2 hours while mixing at 1500 rpm. A solution of 2.5 grams of urea in 7 grams of water was then added to the reaction mixture and reaction was allowed to continue at 70° C. for 40 minutes. The stirring was adjusted to 500 rpm. The pH was adjusted to 9 using a 10% NaOH solution.

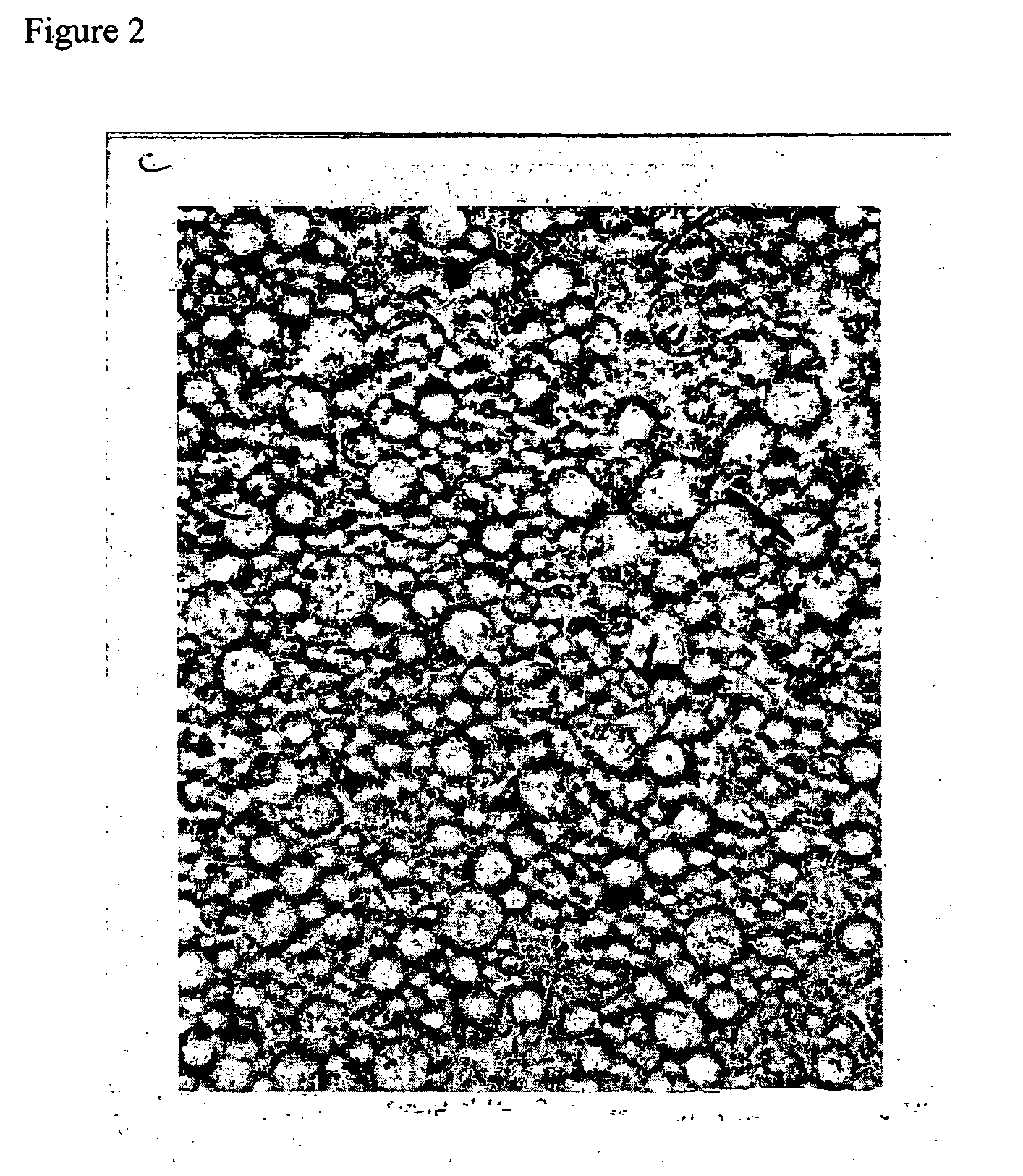

[0115] A drop of microcapsule solution was place on a cover glass and its photomicrograph was taken. The micr...

example 5 (

Invention)

[0116] The organic phase and aqueous phase (Versa TL 502 / TL130: 20 / 80) were mixed using a propeller mixer at 1000 rpm for 10 minutes at room temperature to form a premix. The premix was then passed through a homogenizer once at a pressure greater than 6000 psi. The resultant mixture was heated in a 60° C. bath for 10 minutes before a melamine formaldehyde prepolymer solution was added. The prepolymer was formed by reacting 3.9 grams of melamine and 6.5 grams of 37% formaldehyde solution in 44 grams of water (pH>8). The pH was adjusted to pH 6 with H3PO4 and the reaction mixture was heated to 70 C for 2 hours while mixing at 1500 rpm. A solution of 2.5 grams of urea in 7 grams of water was then added to the reaction mixture and reaction was allowed to continue at 70° C. for 40 minutes. The stirring was adjusted to 500 rpm. The pH was adjusted to 9 using a 10% NaOH solution.

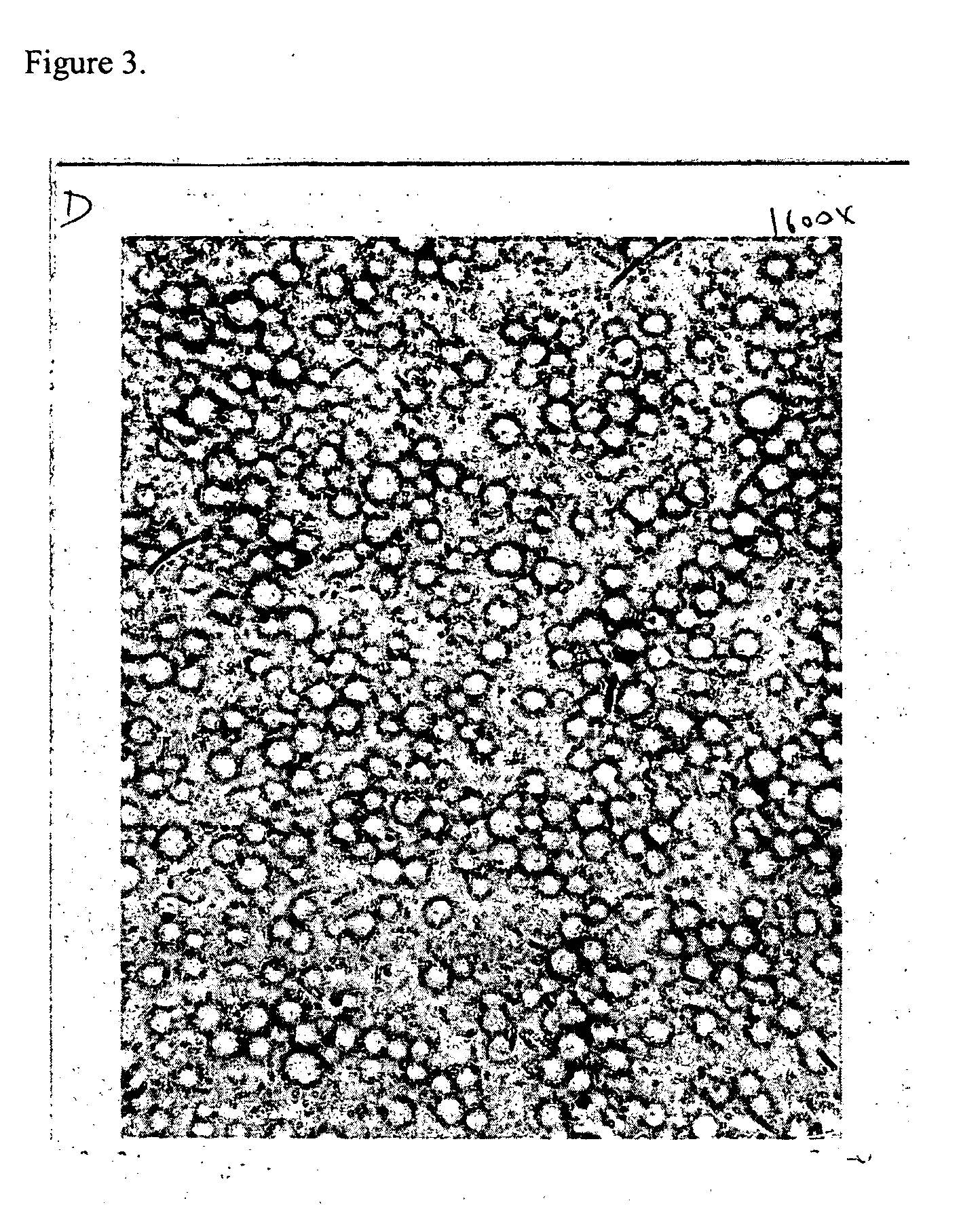

[0117] A drop of microcapsule solution was place on a cover glass and its photomicrograph was taken. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean size | aaaaa | aaaaa |

| mean size | aaaaa | aaaaa |

| mean size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com