Method of preparing polymer composite using unidirectionally solidified giant magnetostrictive material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Preparation of Polymer Composite using Tb0.3Dy0.7Fe1.32

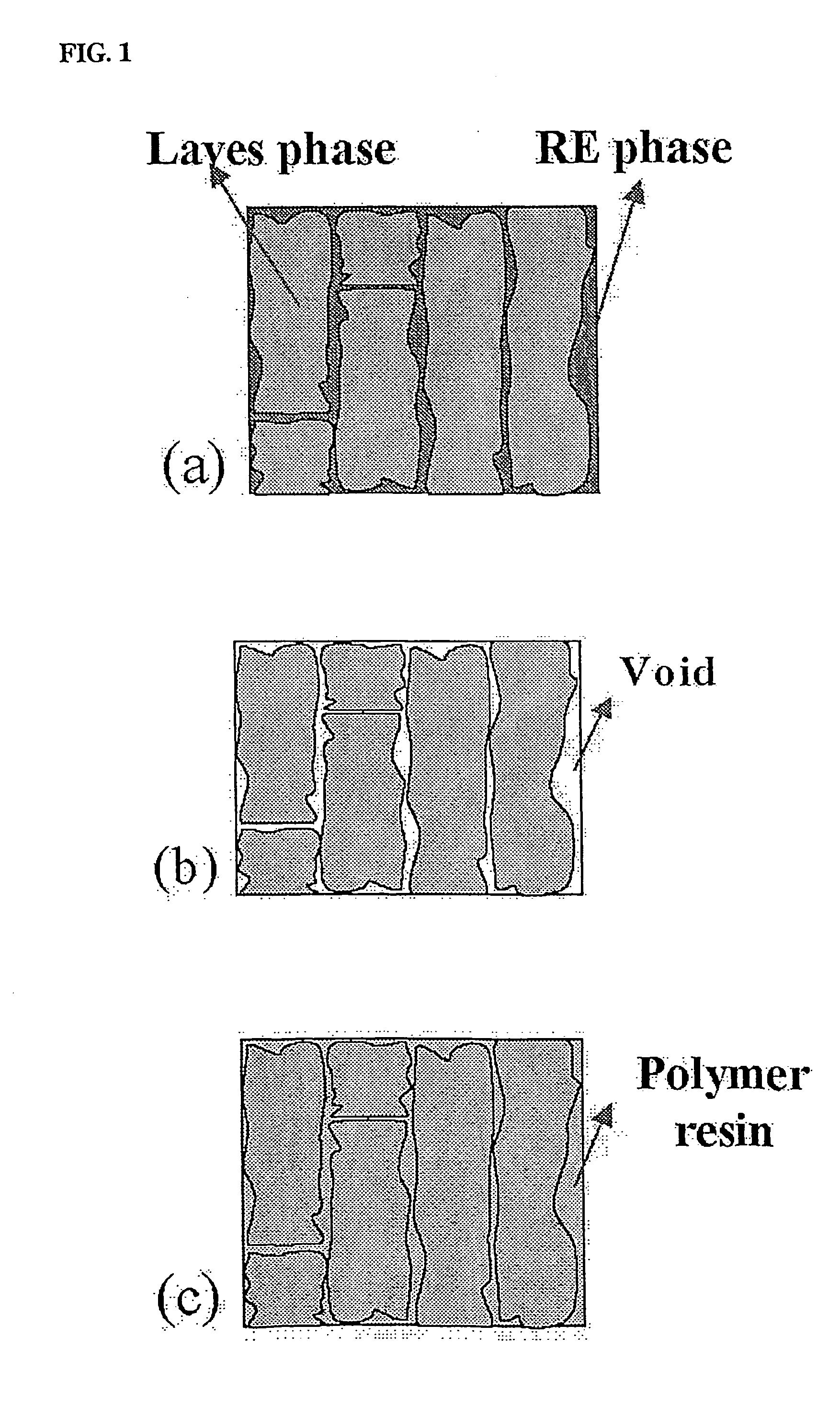

[0040] In the present example, as a giant magnetostrictive material, an alloy comprising 90 vol % of primary REFe2 phase and 10 vol % of eutectic phase was used. In FIG. 4 showing a pseudobinary phase diagram of the alloy, terbium (Tb) and dysprosium (Dy) form a complete solid solution. The “RE” in the drawing means a rare earth phase of TbxDy1-x, and REFe2 is defined as a Laves phase having giant magnetostrictive property.

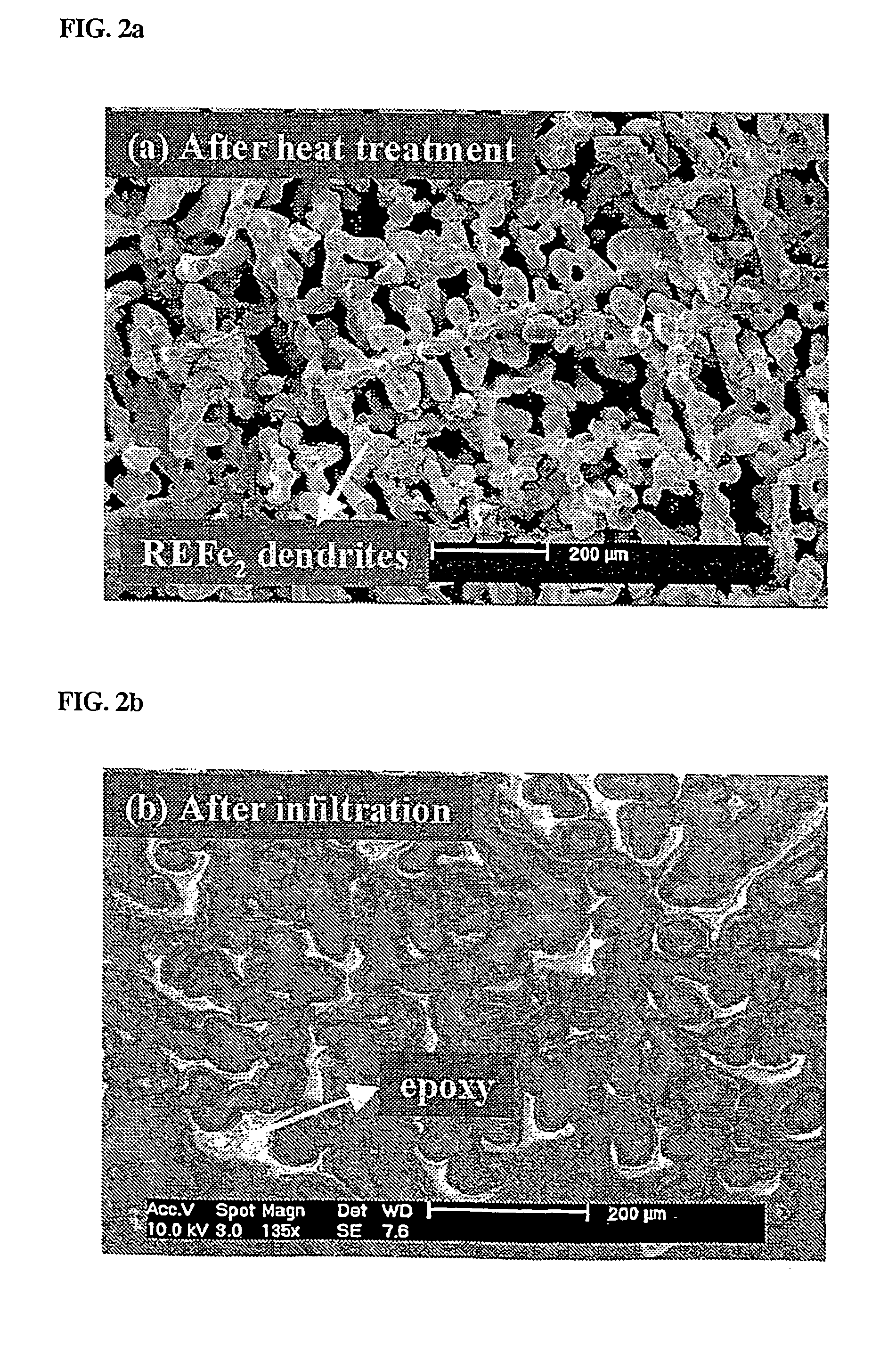

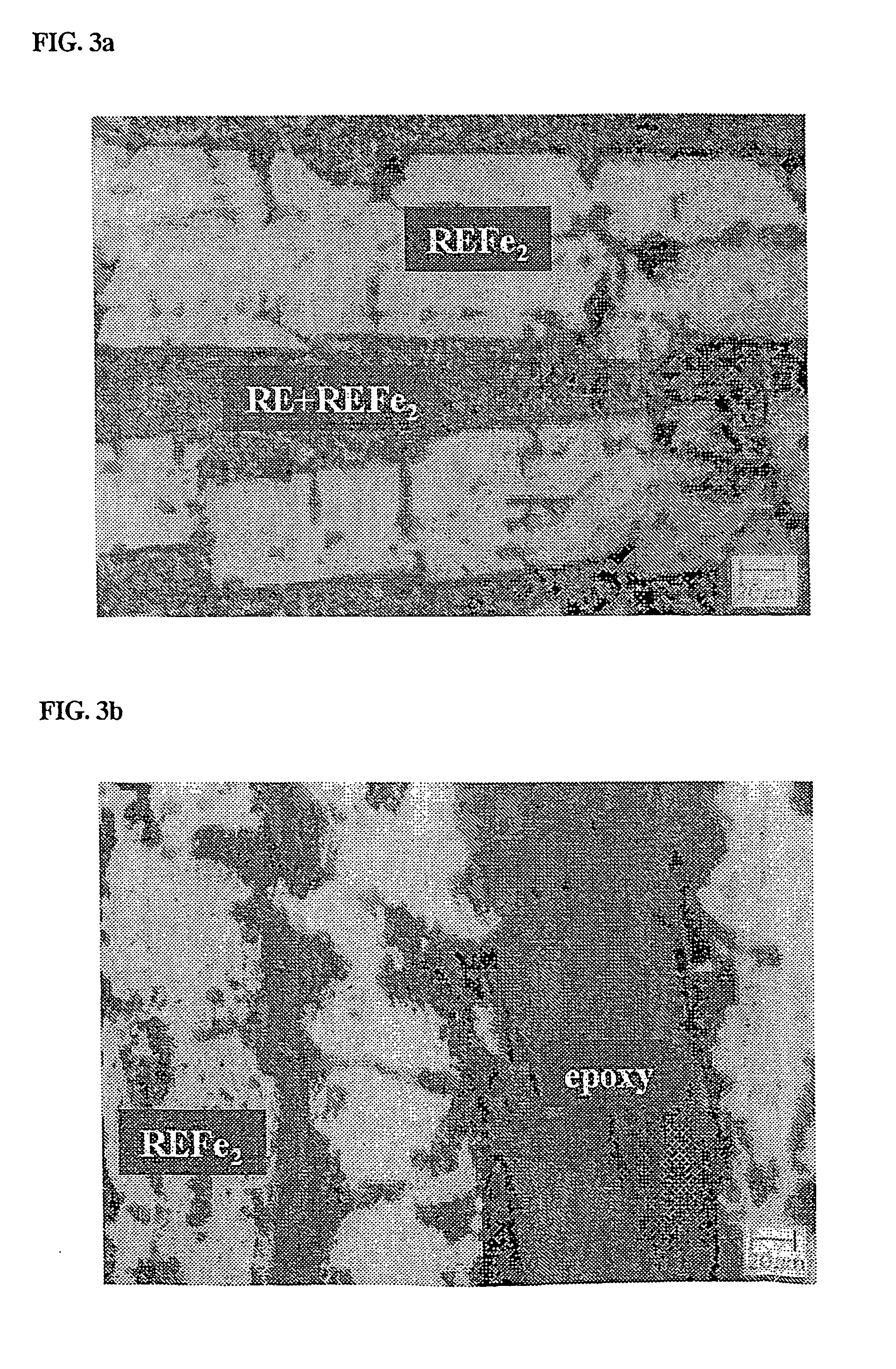

[0041] To prevent the alloy rod from being oxidized at a high temperature, the alloy rod was charged into a quartz tube, which was then filled with highly pure argon gas, and the tube was sealed, followed by performing annealing process at 1000° C. for 6 hours to remove the eutectic phase. A sample having fine open pores was infiltrated with YD-114 epoxy resin as follows. Into a chamber (autoclave) capable of being subjected to evacuation and pressurization, the epoxy resin heated up to 80° C. and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com