Film forming apparatus and film forming method

a film forming and film technology, applied in the direction of coatings, chemical vapor deposition coatings, metallic material coating processes, etc., can solve the problems of large installation space, inability to form flat films, and process not being effectively performed in a long time, so as to reduce the installation space of the facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

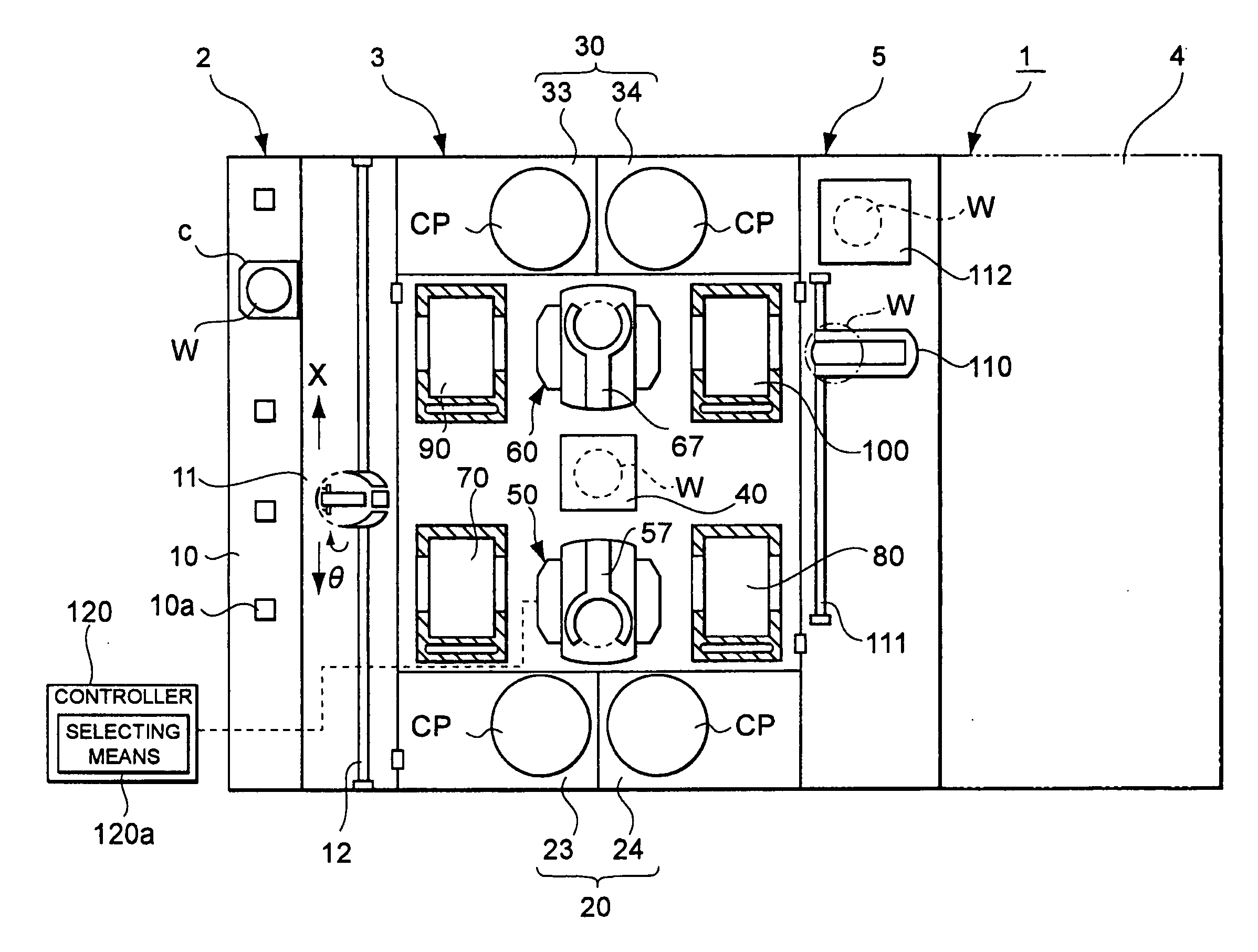

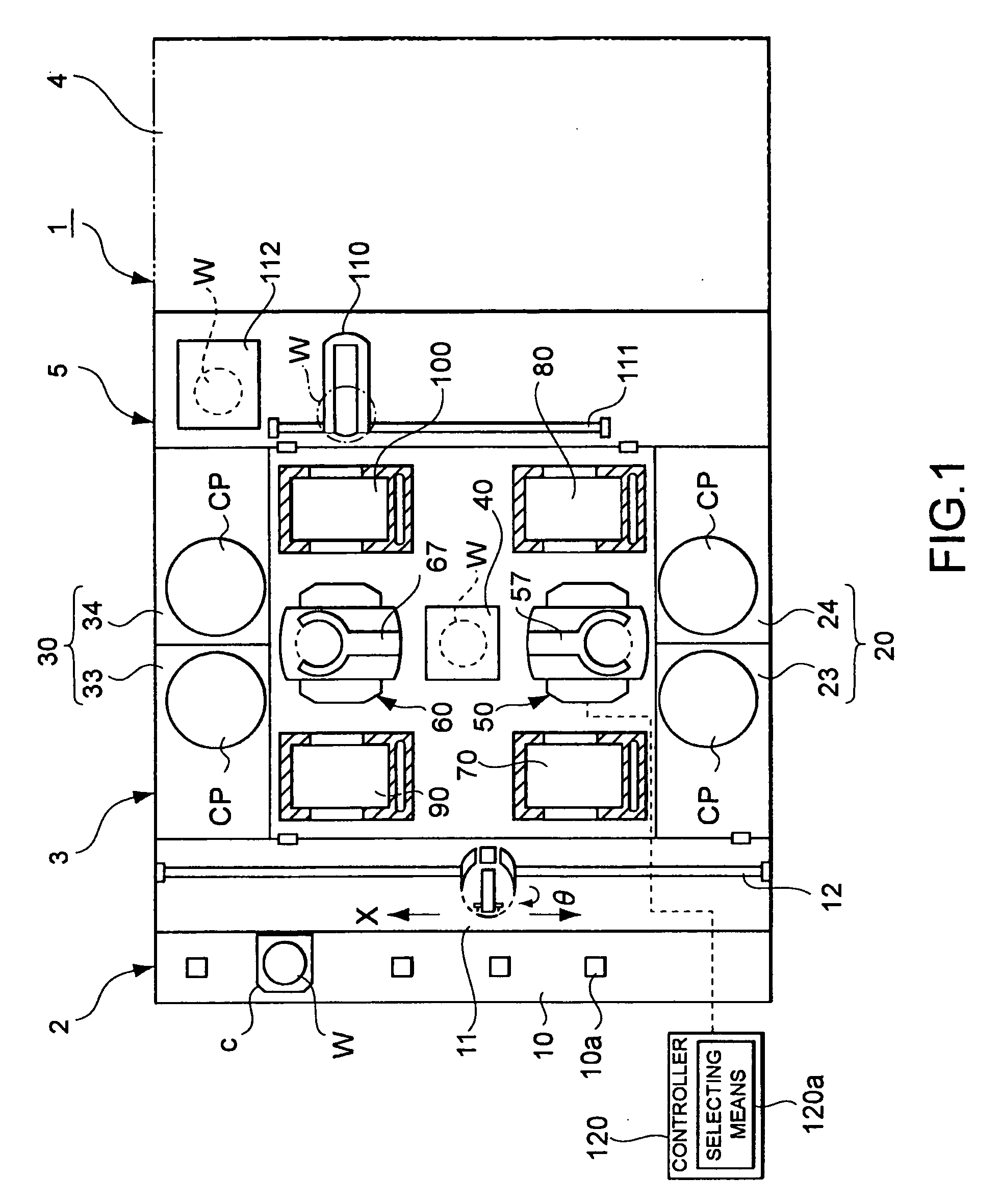

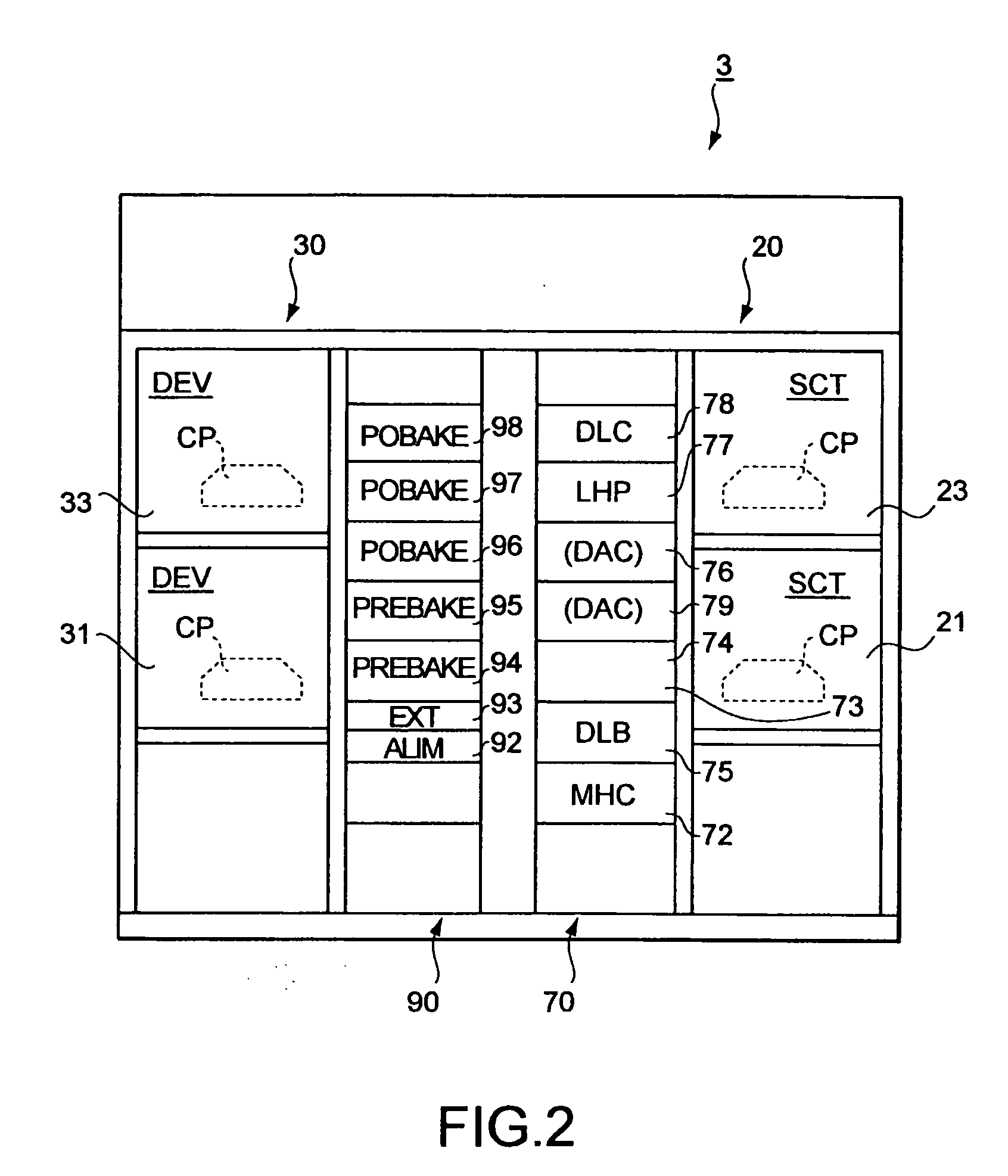

[0034] Next, with reference to the accompanying drawings, an embodiment of the present invention will be described.

[0035] In the embodiment, a fabrication method for a semiconductor device having a laminated film composed of three layers of insulation films in FIG. 5D will be described.

[0036] As shown in FIG. 5D, a lower layer wiring 201 is formed on a semiconductor wafer W (hereinafter abbreviated as wafer W). On the lower layer wiring 201, an inter-layer insulation film composed of layers of laminated films is formed. The inter-layer insulation film is composed of a porous insulation film 202, a non-porous insulation film 203, and a porous insulation film 204. A porous insulation film is a film made with processing a foaming material. In the inter-layer insulation film, for example through-holes (not shown) are formed. Via the through-holes, a wiring (not shown) that is made of a conductive material and formed on the inter-layer insulation film and the lower layer wiring 201 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com