Steel post having corrosion control property for embedded part

a technology of corrosion control and embedded parts, which is applied in the field of lamp posts, can solve the problems of easy corrosion of parts right above where the posts are embedded, and achieve the effect of prolonging the life of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

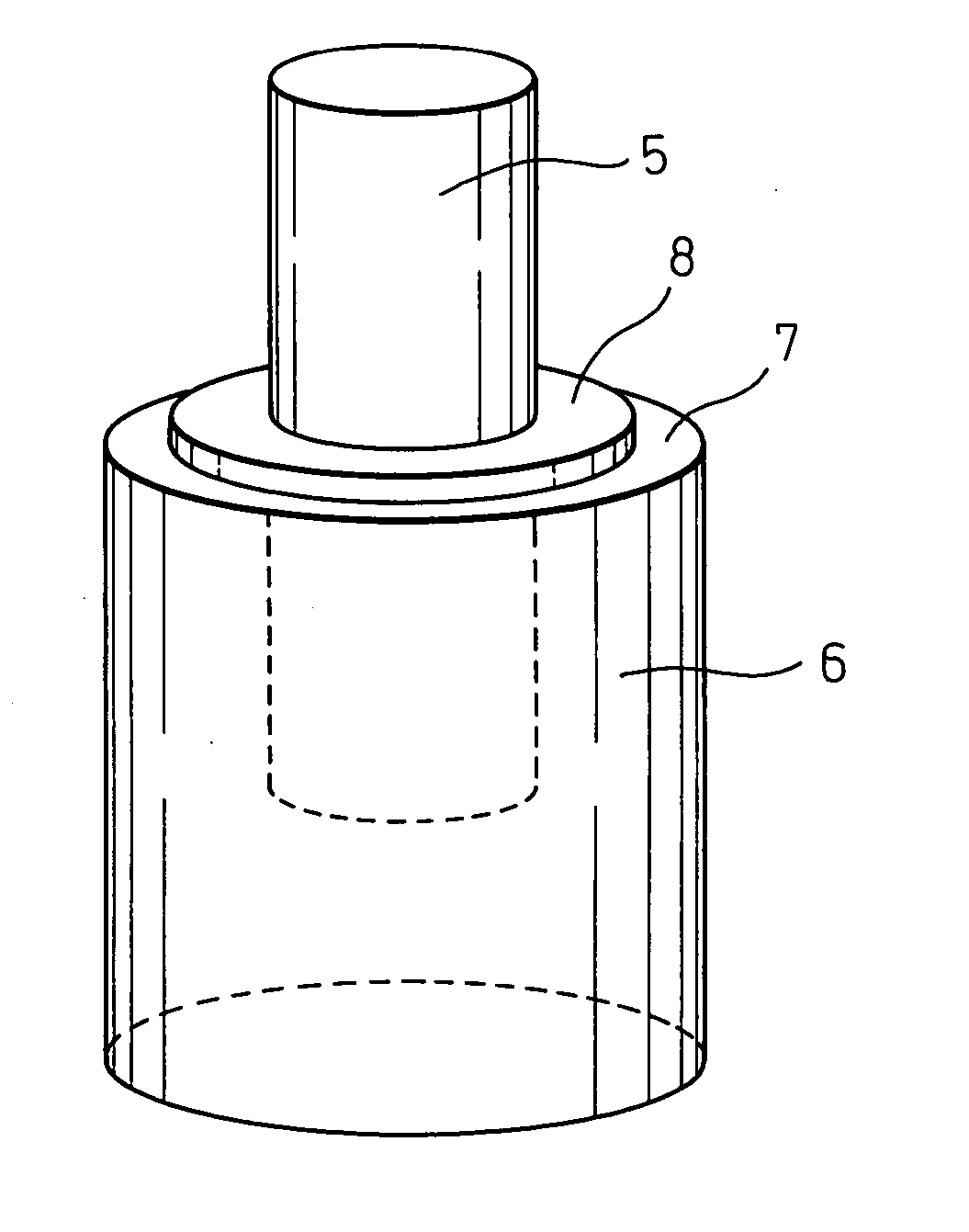

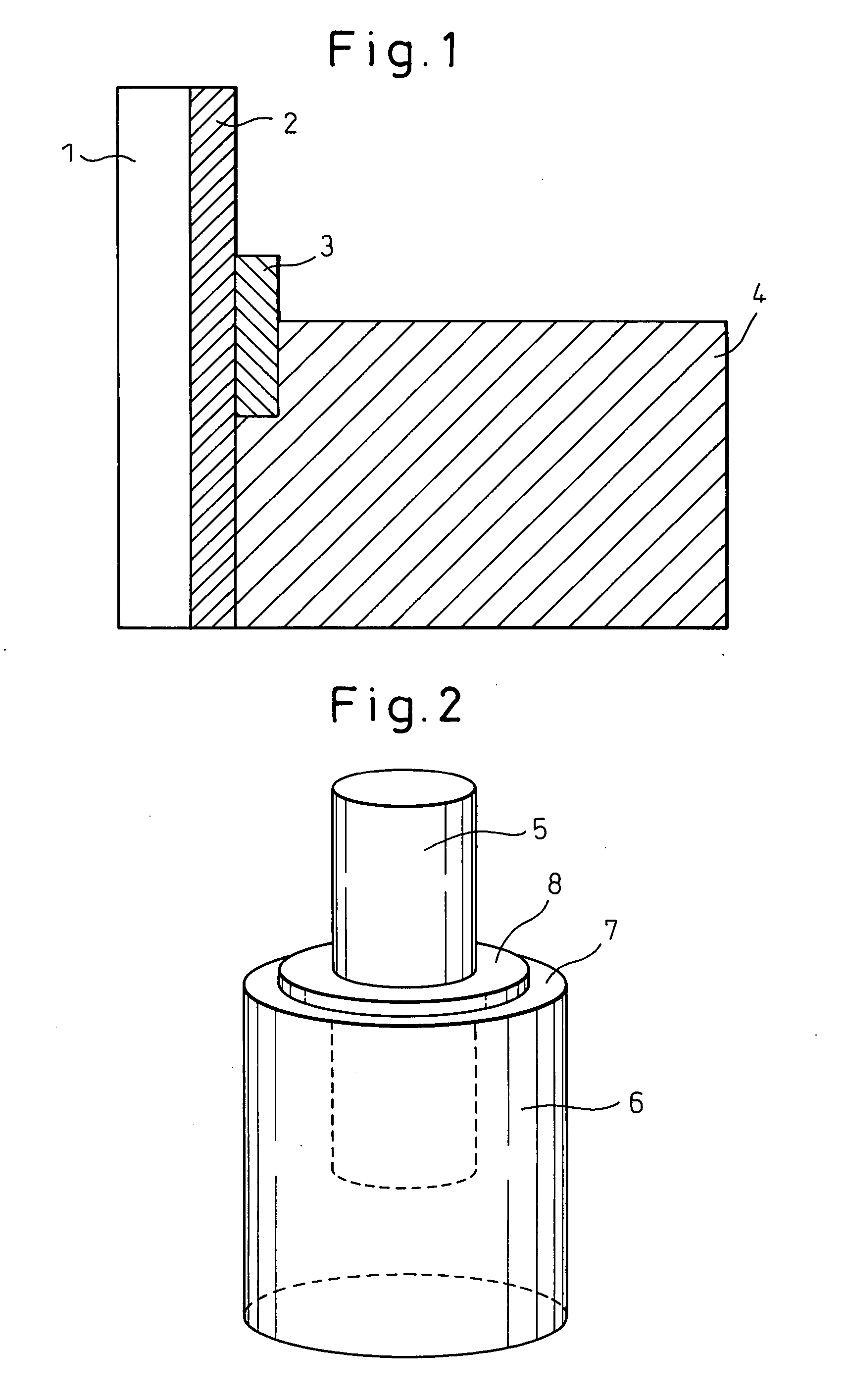

[0028] The test sample shown in FIG. 2 was fabricated. The test sample 5 (steel post) had an outside diameter of 60.5 mm, a length of 200 mm, and a thickness of 3.8 mm. The test sample 5 was given the corrosion-proofing coating shown in Table 2 in advance and further covered with the metal-based corrosion-proofing material shown in Table 2. The sample was embedded in concrete 6 of a diameter of 100 mm to about half of its 200 mm length direction. Further, a 20 mm high PVC frame 7 was placed over the concrete. This was filled with an embedded material 8 comprised of a mixture of commercially available gardening use soil and decomposing leaves etc. The test sample was sprayed once a day with an aqueous solution of substantially the same ingredients as average canine urine shown in Table 1. After six months, the state of corrosion was evaluated by viewing the occurrence of corrosion and any pitting. The tested materials and their test results are shown in Table 2. The steel post accord...

example 2

[0030] Under the conditions prescribed in JIS H 8641, steel pipes of outside diameters of 43 mmφ, lengths of 100 mm, and thicknesses of 3.5 mm plated with zinc were brush coated on their outside surfaces with the ordinary temperature curing epoxy resin coatings comprised of a solution containing 49 wt % of an epoxy resin varnish, 30 wt % of a bulk pigment (titanium oxide), about 2 wt % of other additives, and 6 wt % of a solvent and polymerizing by 13 wt % of a curing agent into which the pigments shown in Table 3 were added in the wt % with respect to the coatings shown so as to thereby form coating layers comprised of corrosion-proofing materials. At this time, for measurement of the ability of each of the pigments to neutralize ammonium, 100 g of an aqueous solution containing 5% ammonium ions was prepared, the pigment described in the table was added in a powder state in an amount of 1%, and the amount when the pH fell to 1 or more was deemed as the ability to neutralize ammoniu...

example 3

[0032] Steel pipes of inside diameters of 150 mmφ, thicknesses of 6 mm, and lengths of 3 m were zinc plated by the method prescribed in JIS H8641 and covered by the corrosion-proofing material of the specification 1 shown in Example 1 to a range of 500 mm from a location 500 mm from the bottom end of the surface, covered by the corrosion-proofing material of the specification 7 of Example 1, or covered by the corrosion-proofing material of the specification 26 of Example 2 and, as a comparative example, a steel pipe not covered by an corrosion-proofing material were prepared. These steel pipes were embedded in concrete so that locations 750 mm from the bottom ends were exposed at the concrete surface. Soil was covered over the top of these to a thickness of 50 mm to obtain test samples.

[0033] These test samples were sprayed once a day with solutions of the ingredients shown in Table 1. These were examined after the elapse of one year, whereupon it was found that the comparative mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com