Track bushing and method and apparatus for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Heating Test 1

[0154] In this example, the saddle-shaped heating inductor 11 having ferrite iron 14 embedded in the inner circumferential surface thereof as shown in FIG. 9 was used as the heating inductor for induction heating. The outer circumferential surface cooling jacket 12 was disposed on the peripheral side of the saddle-shaped heating inductor 11 and the guide tube (water guide tube) 2 for cooling water was disposed in the bore of the heating inductor 11. The length of the embedded ferrite iron 14 was substantially equal to the length of the track bushing 1. The saddle-shaped heating inductor 11 was about 3 mm away from the outer circumferential surface of the track bushing 1. A high frequency heating power source of 6 kHz and 300 kW was used. In FIG. 9, reference numeral 13 designates an insulating material.

[0155] As shown in FIG. 10, the track bushing 1 was fixed at its upper and lower ends by means of the upper partition jig 7 and lower partition jig 8 for dividing the ...

example 2

Heating Test 2

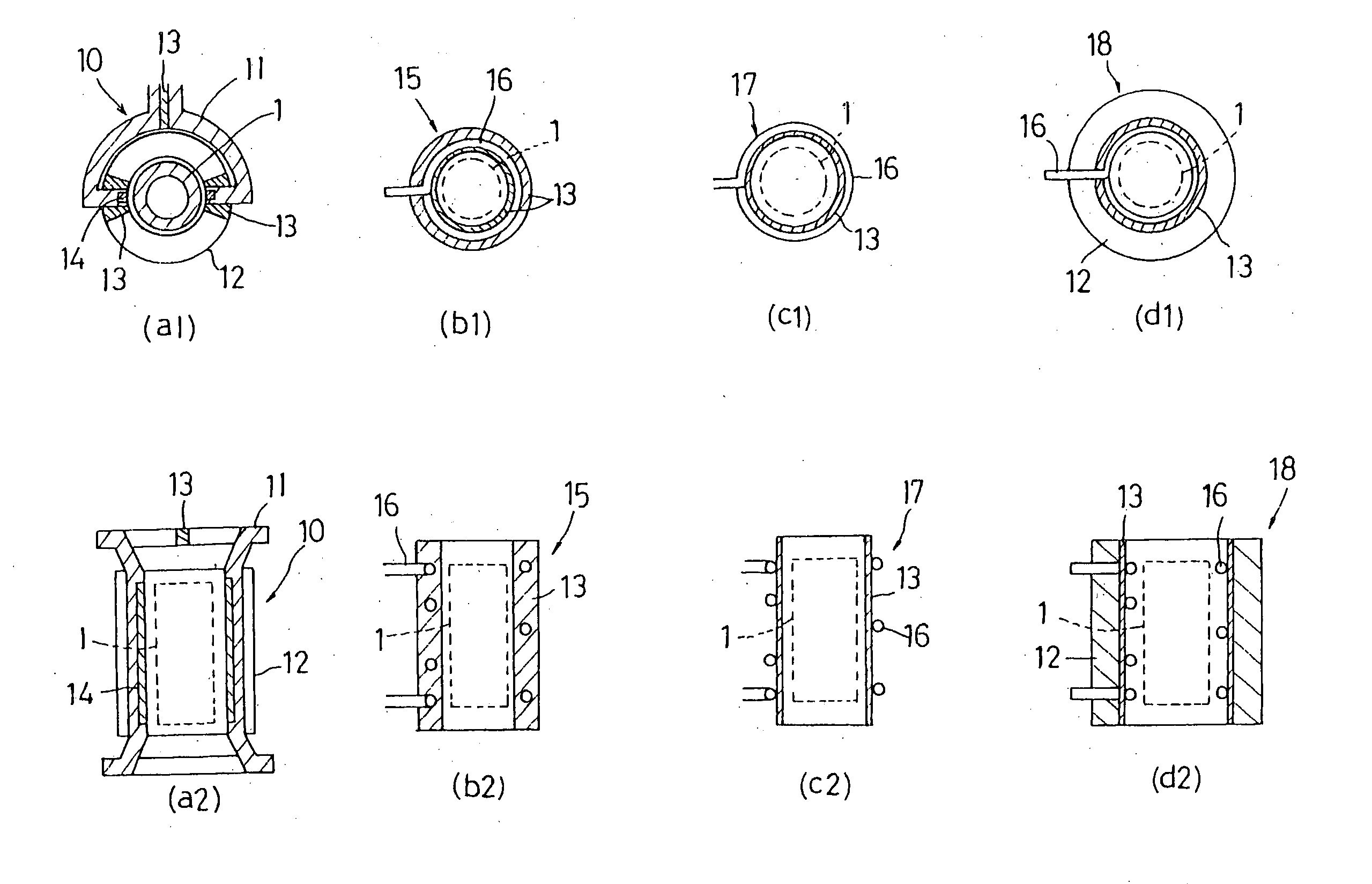

[0158] In this example, induction heating was done, using the spiral coil 16 such as shown in FIG. 12 for the track bushing B in order to prevent the electric discharge phenomenon observed in Example 1. The basic design of the spiral coil 16 is as follows: A copper tube of φ 10 mm was wound such that the coil spacing was 10 to 25 mm, the inside diameter of the coil was about 15 mm larger than the outside diameter of the track bushing, and a ½ turn at each coil end was parallel with the associated end face of the track bushing. The same high frequency power source as in Example 1 was used to heat the track bushing B with an input power of 110 kW per bushing. The time required for heating the track bushing B to about 950° C. was about 12 seconds.

[0159] Where heating was carried out using partition jigs (see FIG. 10) made from SUS304, it was found that the electric discharge phenomenon at the contact parts of the partition jigs was not observed and the abnormal heating ...

example 3

Inner Circumferential Surface Cooling System and Observation of Cooling Condition

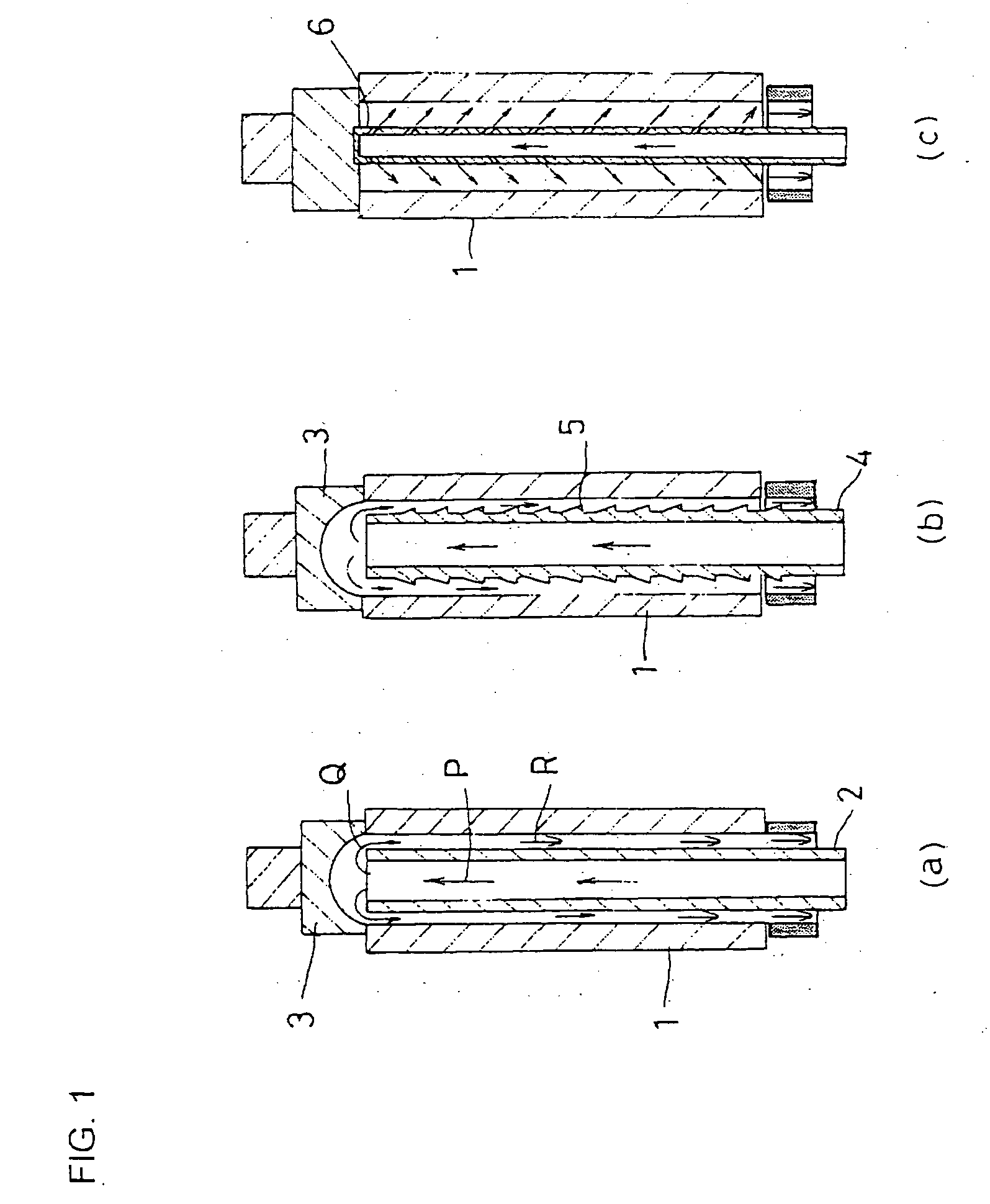

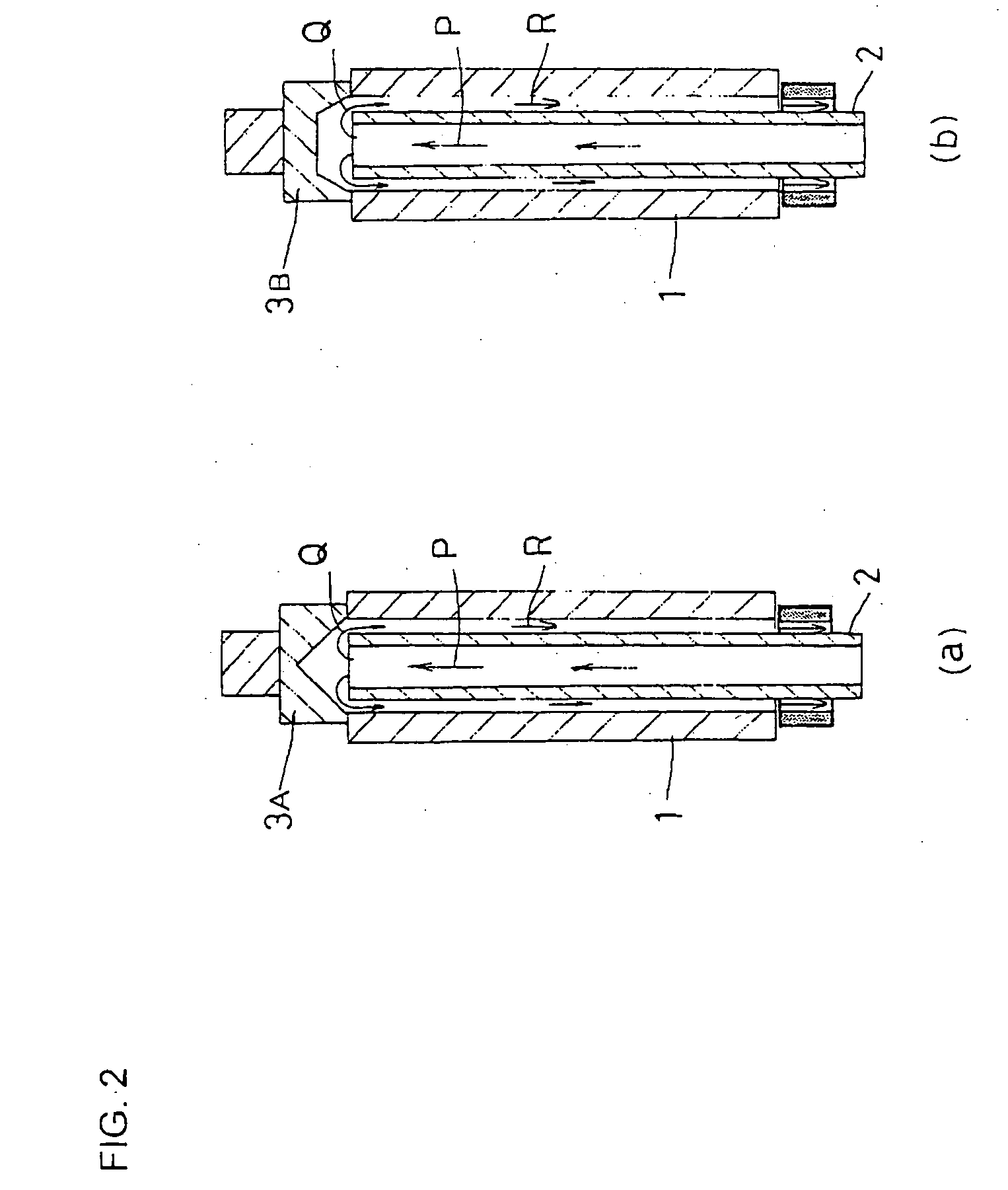

[0162] In Example 3, a flowing test by visual inspection was made in the following way: Water was used as the cooling medium for inner circumferential surface cooling and a transparent, cylindrical acrylic resin tube having the same inside diameter as that of the track bushing was used in place of the track bushing. More concretely, the outside diameter of the guide tube 2 for cooling water was varied so as to be 2, 4, 8, 10 and 20 mm smaller than the inside diameter of the track bushing (acrylic resin cylindrical tube) 1 as shown in FIG. 13. By use of the upper partition jig 7 including a spherical surface having a slightly smaller diameter than the inside diameter of the track bushing 1, cooling water was flowed downwardly from above the cylindrical axis of the track bushing into the space defined by the inner circumferential surface of the track bushing 1 and the outer circumferential surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com