Power generation methods and systems

a power generation method and power supply technology, applied in the direction of generators/motors, machines/engines, light and heating equipment, etc., can solve the problems of low solar energy power, many problems currently exist in traditional power generation methods and systems, and many problems, to achieve the effect of low cost/efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

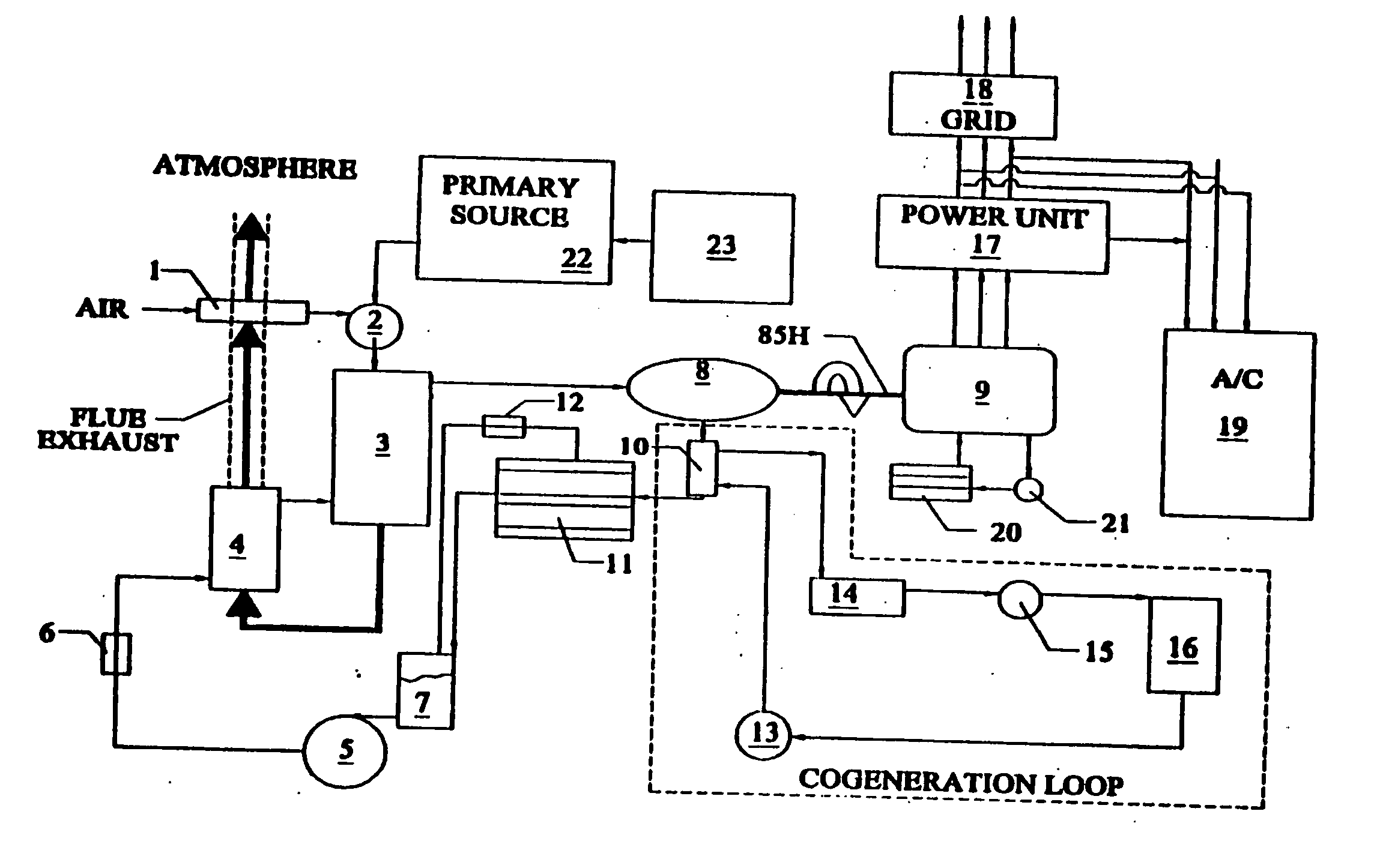

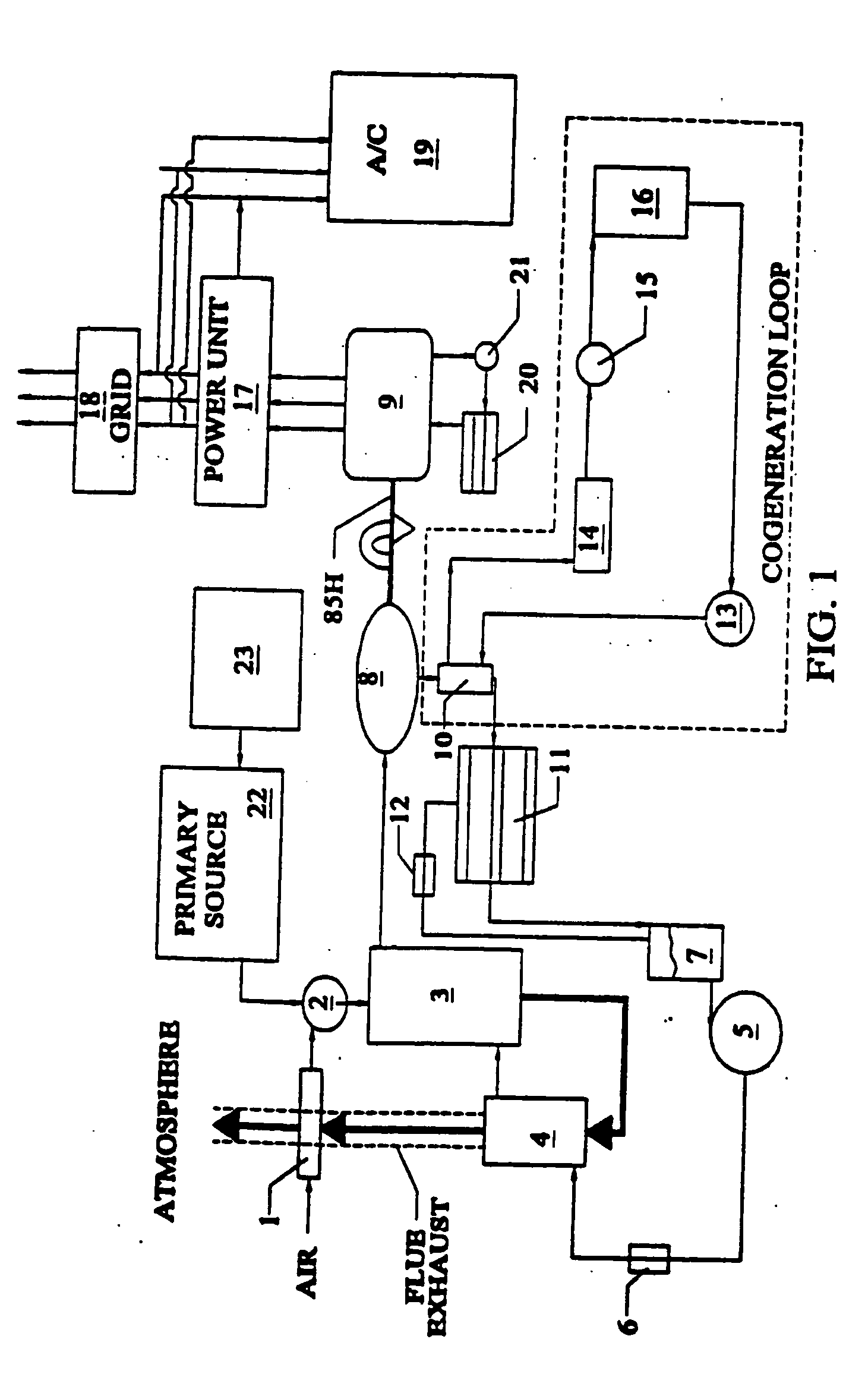

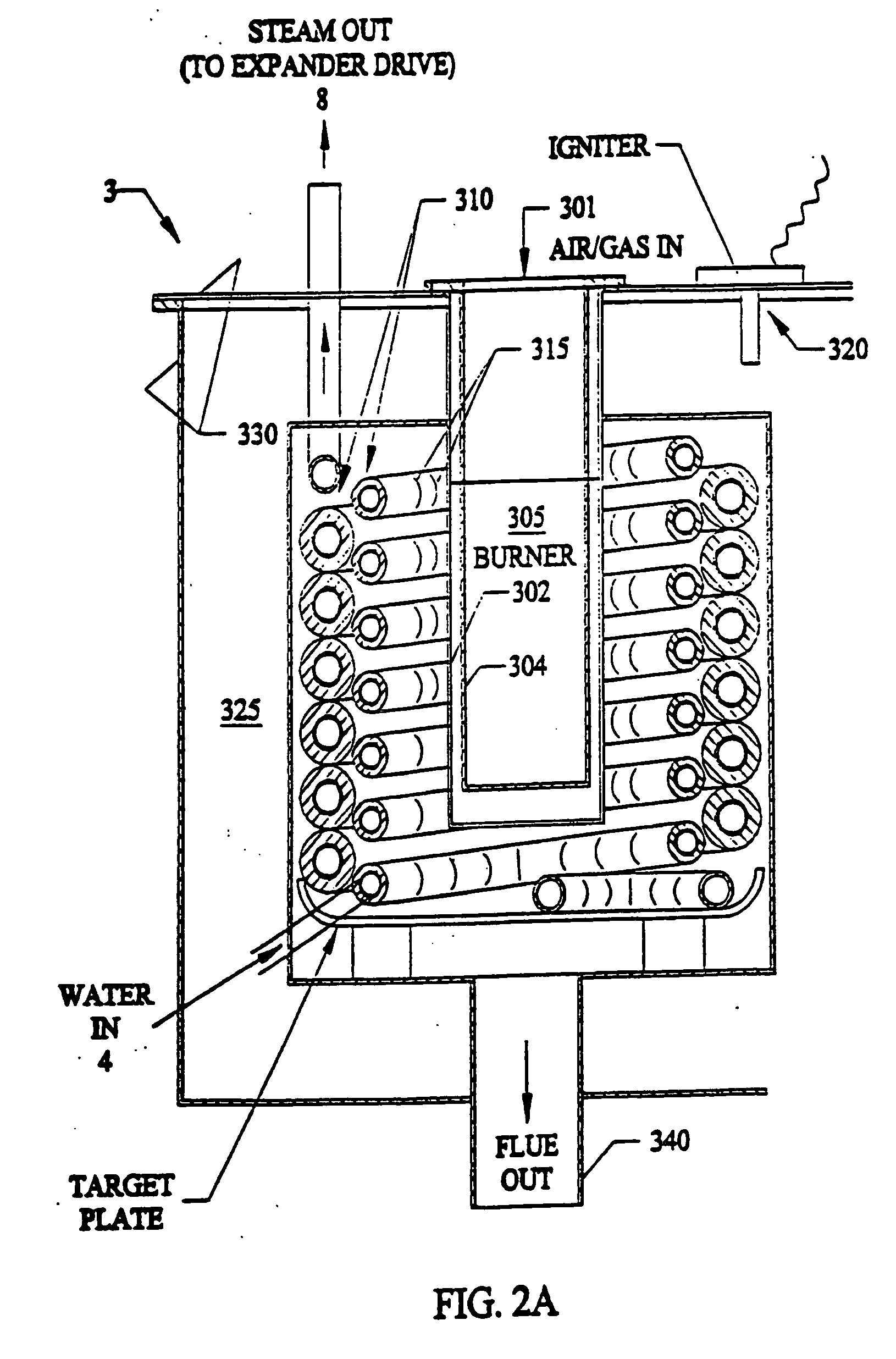

embodiment 1000

[0131]FIG. 13 shows a second preferred embodiment 1000 for heat generation using a closed loop steam generator system 1200, 1400, 1500, 1600, 1700. The steam generator (boiler 8) 1100 referenced above in FIGS. 2-3 turns water into steam by burning a fuel source (22FIG. 1) such as natural gas, propane, and any vaporous fuel. Generated steam having a temperature of approximately 280 to approximately 1000 degrees, and a pressure range of approximately 100 to approximately 600 psi. The generated steam has an efficiency rating of turning water into steam of up to approximately 98%, with flue gases being up to the remaining approximately 2%. The steam enters a steam to water condenser exchanger 1200 (10FIG. 7) where the steam is changed back to water back into the heat (steam) generator by high pressure condensate return pump 1300 (5FIG. 9).

[0132] Operation of novel closed loop heat cycle. From the condenser heat exchanger 1200 water passes to hot water circulator 1400 (such as off-the-sh...

embodiment 2000

[0135]FIG. 14 shows a third preferred embodiment 2000 for powering an air-conditioner unit using the novel steam generator 2100, expander 2400 (8FIGS. 5A, 5B, 6) and steam condenser 2200 of the invention, which is a vaporous fuel supplied air conditioner. The steam generator 2100 referenced above in FIGS. 2A-2B turns water into steam by burning a fuel source such as natural gas, propane, and any vaporous fuel. Generated steam having a temperature of approximately 280 to approximately 1000 degrees, and a pressure range of approximately 100 to approximately 600 psi. The generated steam has an efficiency rating of turning water into steam of up to approximately 98%, with emitted flue gases being up to the remaining approximately 2%. The steam enters expander drive 2400 (described above in reference to FIGS. 5A, 5B, and 6), which rotates output driveshaft 2450 which is mechanically connected to a direct drive compressor 2510 such as but not limited to a Copeland Inc. shaft driven compre...

embodiment 3000

[0138]FIG. 15 shows a fourth preferred embodiment 3000 for supplying electricity to any electrically powered device or system using the novel steam generator 3100 (boiler 8FIGS. 2A, 2B), expander drive 3400 (8FIGS. 5A, 5B and 6) and steam condenser 3200 of the invention. The steam generator 3100 referenced above in FIGS. 2A-2B turns water into steam by burning a fuel source 22 such as natural gas, propane, and any vaporous fuel. Generated steam having a temperature of approximately 280 to approximately 1000 degrees, and a pressure range of approximately 100 to approximately 600 psi. The generated steam has an efficiency rating of turning water into steam of up to approximately 98%, with emitted flue gases being up to the remaining approximately 2%. The steam enters expander drive 3400 (described above in reference to FIGS. 5A, 5B and 6)), which rotates output driveshaft 3450 which is mechanically connected to an shaft driven electrical generator 3500 such as but not limited to Smart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com