Heat and electromagnetic wave generator

a generator and heat technology, applied in the field of electrochemical cells, can solve the problems that neither batteries nor electrolytic cells have historically produced large quantities of heat, and achieve the effect of optimizing the heat release of the electrolytic cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

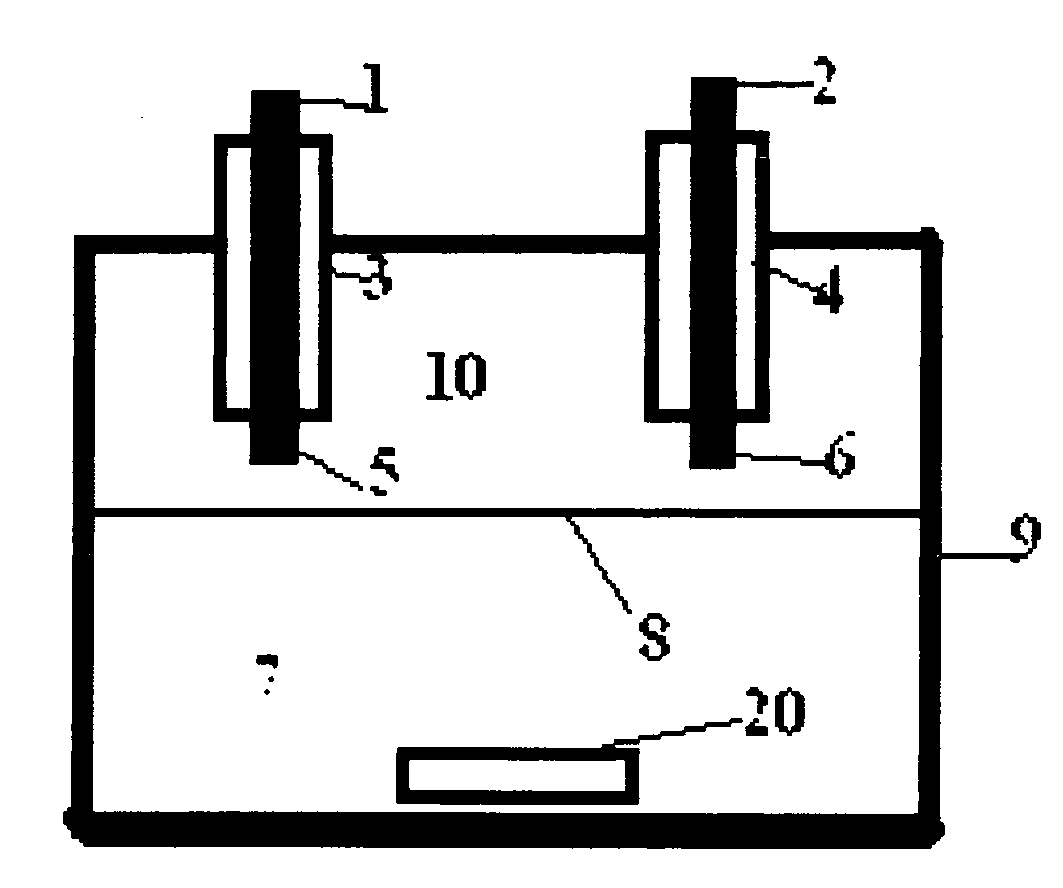

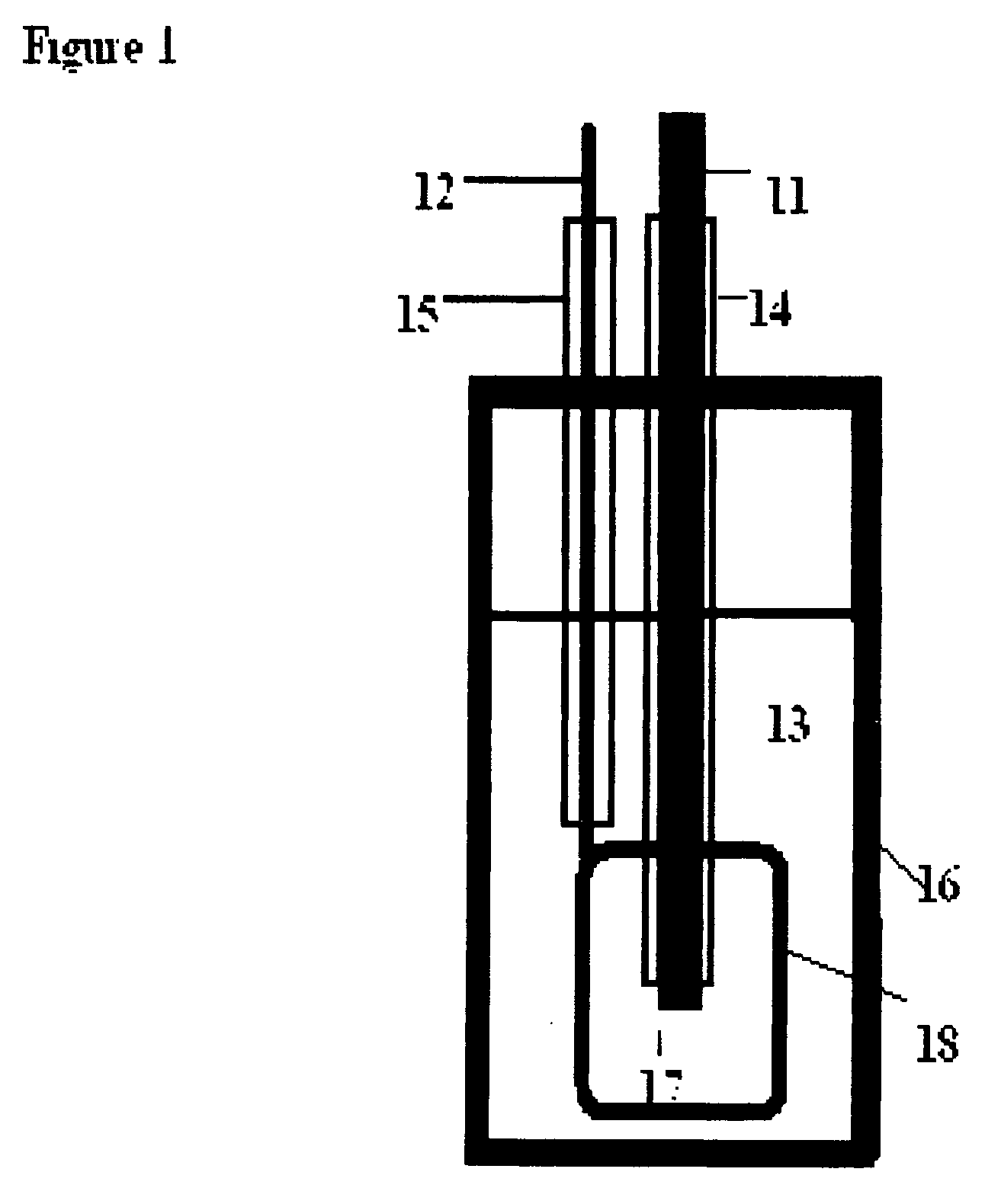

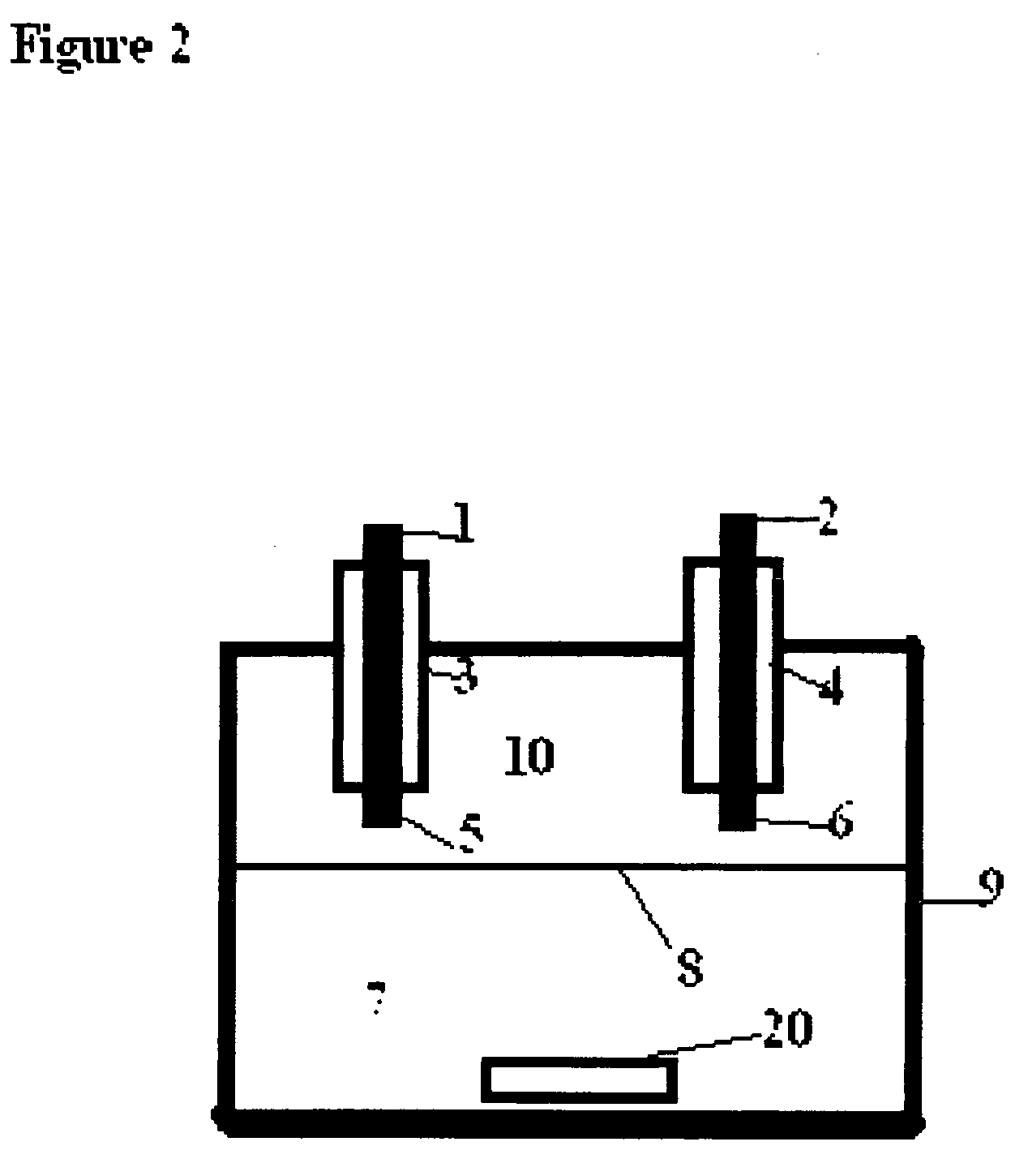

[0022]FIG. 1 illustrates the basic invention and its parts in one embodiment. In this concentric arrangement the central electrode, 11, is the smaller of two electrodes. This was formed by a 3 / 16 Thoriated tungsten welding rod with 2% Th. A second electrode, 12, is constructed of a Platinum gauze cylinder. Such Pt electrodes are well known in the art of electrochemistry. The Pt gauze cylinder was 1 cm in diameter and was designed so that it formed a cage, 18 around electrode 11. Both electrodes where insulated from unwanted chemical events by glass tubing, 14,15 that also supplied support and assure stable spacing between the two electrodes. The containment vessel, 16, in one embodiment was a 250 ml tall form beaker with a Teflon lid. For most operations, the vessel's construction is not critical, however, when the invention is used to generate various electromagnetic waves, it should be constructed from materials that freely pass the desired wavelength. For example, when long wave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com