Method for electrolytic water disinfection without cathodic hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

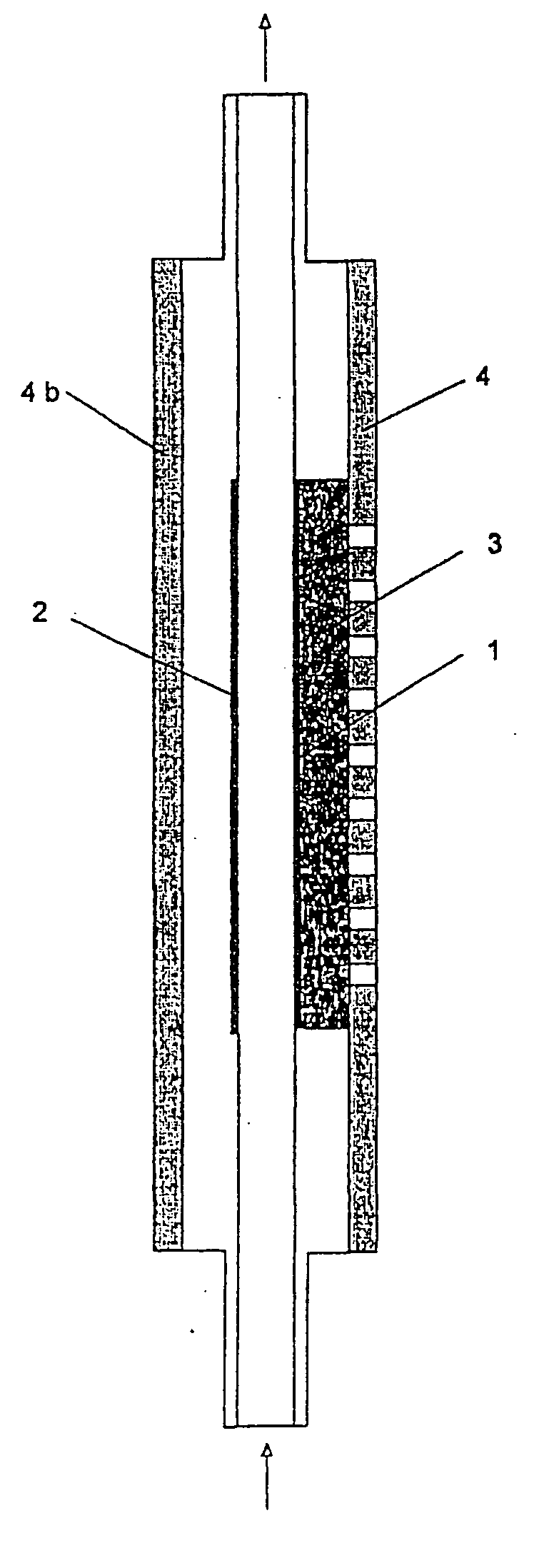

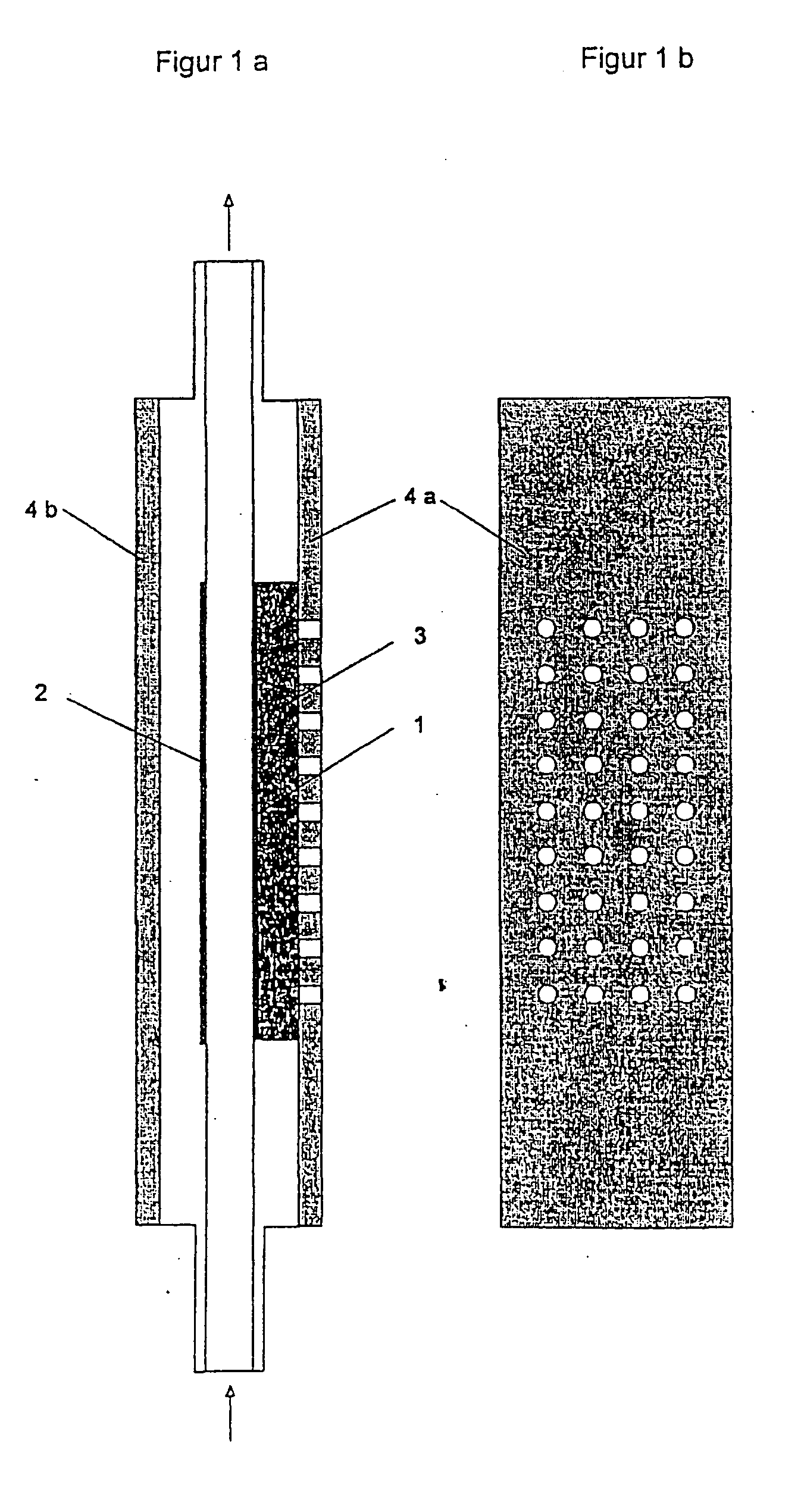

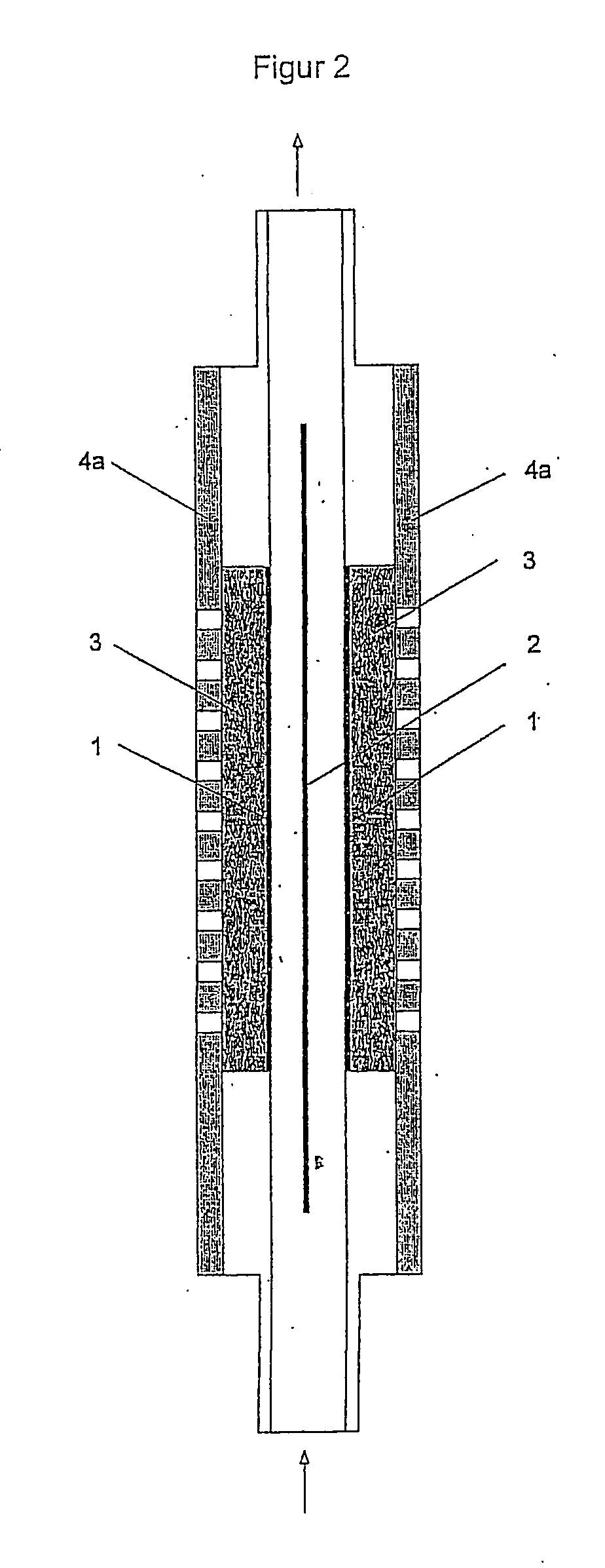

[0026] 1. FIG. 1a is a sectional view of a complete electrolytic cell. The cell follows the principle of a frame-type pressure cell. Between two pressure plates (4a and 4b) are fixed an anode (2) and a gas-diffusion electrode as the cathode (1). The pressure plate 4b (FIG. 1b) is here perforated over the area of the gas-diffusion electrode. The gas-diffusion electrode is mechanically stabilised over the entire surface by a porous support plate (3). A porous filter material (40% porosity) of pure polyethylene was used as the support material. Unrestricted access of air to the gas-diffusion electrode is possible. Water flows through the cell from top to bottom.

[0027] a) For the electrolytic generation of free chlorine as a disinfectant, a titanium electrode coated with iridium, produced by the company Metakem GmbH Usingen, is used as the anode. The gas-diffusion electrode comprises a metal wire netting or expanded metal (e.g. Ni, Fe, Ti) and a graphite layer with catalysts (e.g. Mn, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com