Biodegradable nanocomposites with enhance mechanical properties for soft tissue

a biodegradable and soft tissue technology, applied in the direction of synthetic polymeric active ingredients, organic active ingredients, prosthesis, etc., can solve the problems of non-biodegradable components, biocompatible, biodegradable nanoparticles to strengthen matrices intended for in vivo use,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Biodegradable Elastomeric Polymers

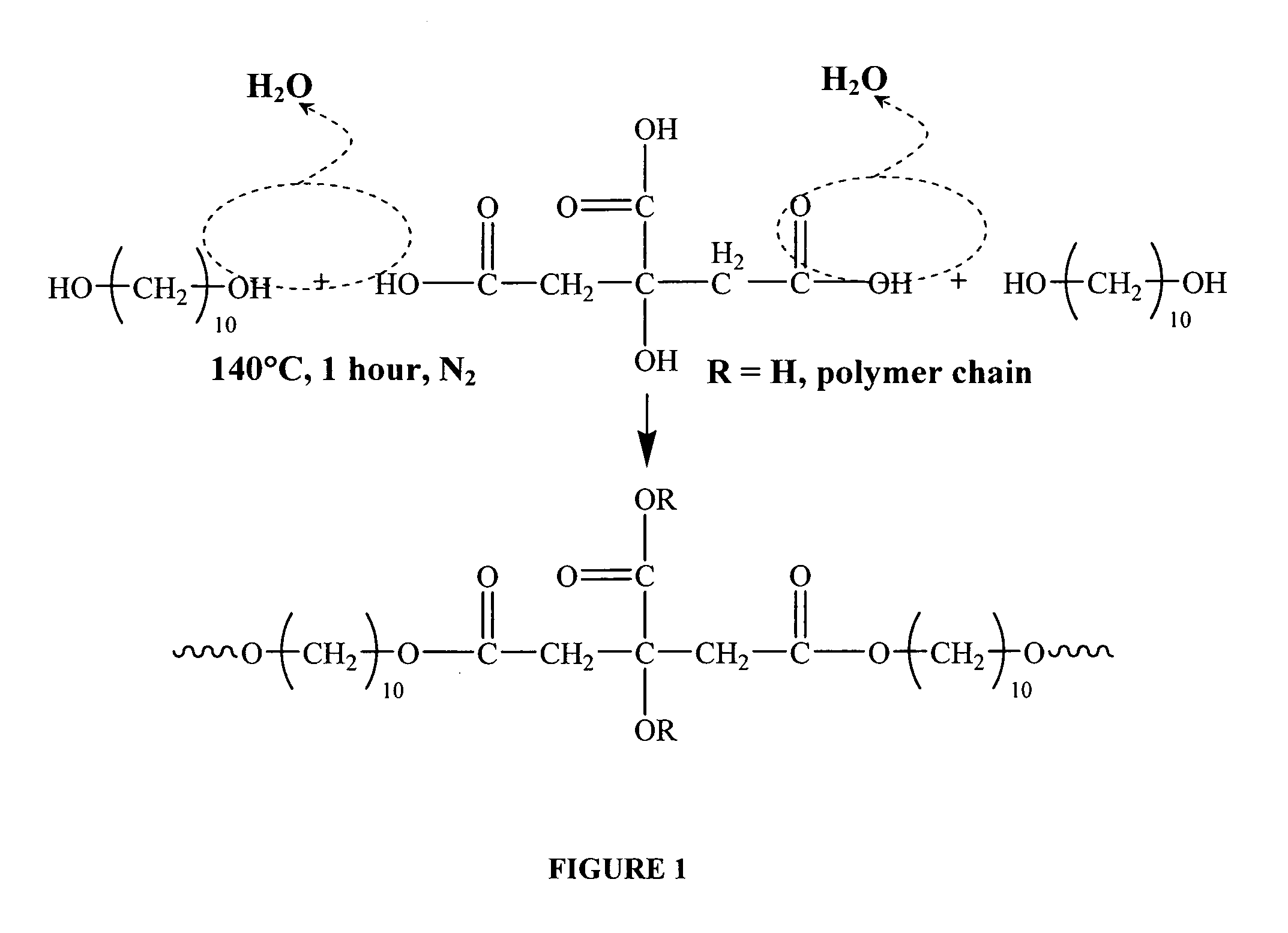

[0056] The nanoparticle compositions of the invention are based on biodegradable elastomeric polymers of poly(diol) citrate molecules. Such molecules typically comprising a polyester network of citric acid copolymerized with a linear aliphatic di-OH monomer in which the number of carbon atoms ranges from 2 to 20. Polymer synthesis conditions for the preparation of these molecules vary from mild conditions, even at low temperature (less than 100° C.) and no vacuum, to tough conditions (high temperature and high vacuum) according the requirements for the materials properties. By changing the synthesis conditions (including, but not limited to, post-polymerization temperature, time, vacuum, the initial monomer molar ratio, and the di-OH monomer chain length) the mechanical properties of the polymer can be modulated over a wide range. This series of polymers exhibit a soft, tough, biodegradable, hydrophilic properties and excellent biocompatibility in ...

example 2

Biodegradable Poly(diol citrate) Nanocomposite Elastomers for Soft Tissue Engineering

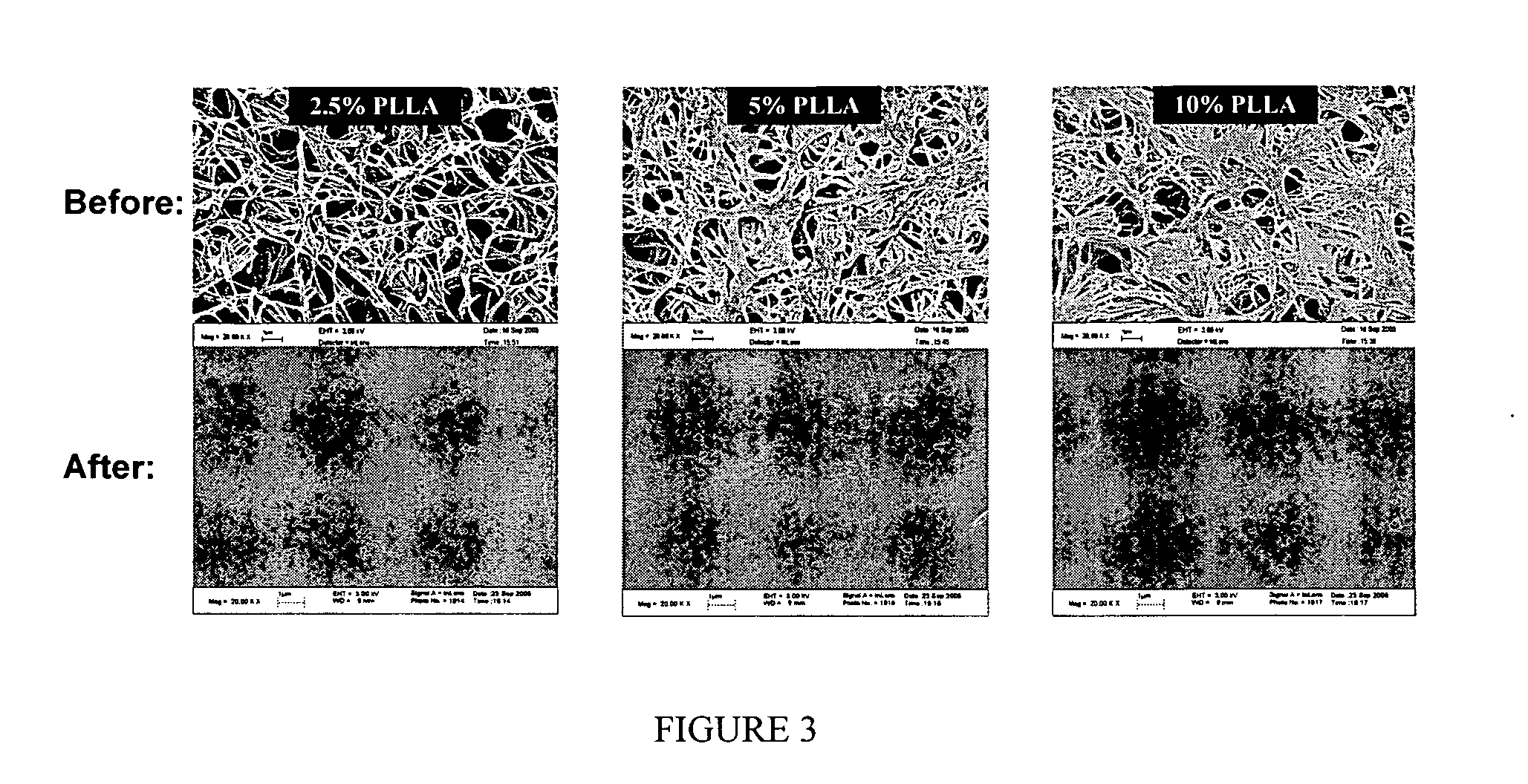

[0096] At present, synthetic biodegradable polymers commonly used for scaffolds in tissue engineering have a limited range of mechanical properties. This limitation is a challenge to in vivo tissue engineering, as the cell-scaffold construct is expected to maintain or restore normal tissue biomechanics during new tissue formation. The biodegradable elastomeric nanocomposite materials described in the present invention are such that their mechanical properties can be tailored to meet the requirements of soft tissue engineering applications. The nanocomposite consists of a nanofibrous poly(1-lactic acid) (PLLA) nanophase and an elastomeric poly(diol citrate) macrophase. Incorporation of a PLLA nanophase provides reinforcement to the poly(diol citrate) as demonstrated by an increase in tensile strength, modulus, and elongation at break with minimal permanent deformation. The mechanical properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| degradation time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com