Method of water purification

a water purification and water technology, applied in water/sludge/sewage treatment, solid sorbent liquid separation, cation exchangers, etc., can solve the problems of ineffective current disinfection procedures, rapid spread of infection among pool users, and known contamination of public swimming pools, so as to maximize the surface area available and be convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Direct Adsorption on Alumina

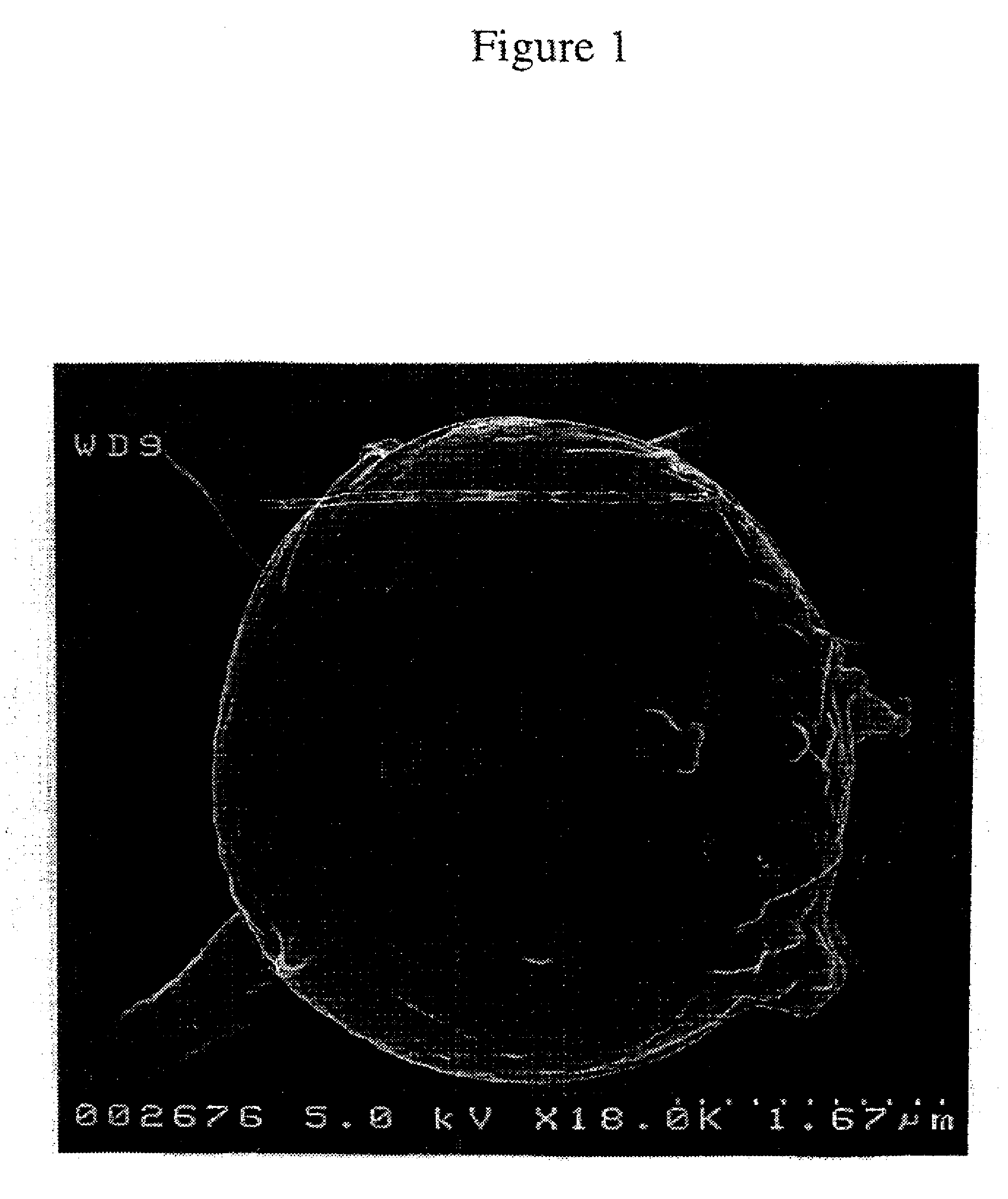

[0062] The Cryptosporidium oocyst sample received from AWT was 5×106 oocysts / ml. Since the oocysts are approximately 5 μm in diameter, the area per oocyst of 1.9×10−7 cm2 means the number of oocysts required to cover a 1 cm2 substrate is 5×106. In these studies we have used 0.1 ml samples of the original 5×106 oocysts / ml sample.

[0063] Pure alumina (α-Al2O3) wafers were cut to an appropriate size and UV irradiated at (λ185 and 254 mm) for 1 hr in the presence of water vapour to remove any organic contamination. The UV irradiation in the presence of water vapour and oxygen produces ozone and hydroxyl radicals which clean the alumina surfaces rendering them hydrophilic. After UV irradiation a small droplet of distilled water was placed on the substrates to ensure the surfaces were hydrophilic, then blown dry under a gentle stream of nitrogen.

[0064] The blank substrates were examined under a Kombistereo Wild M32 light microscope having a magnification rang...

example 2

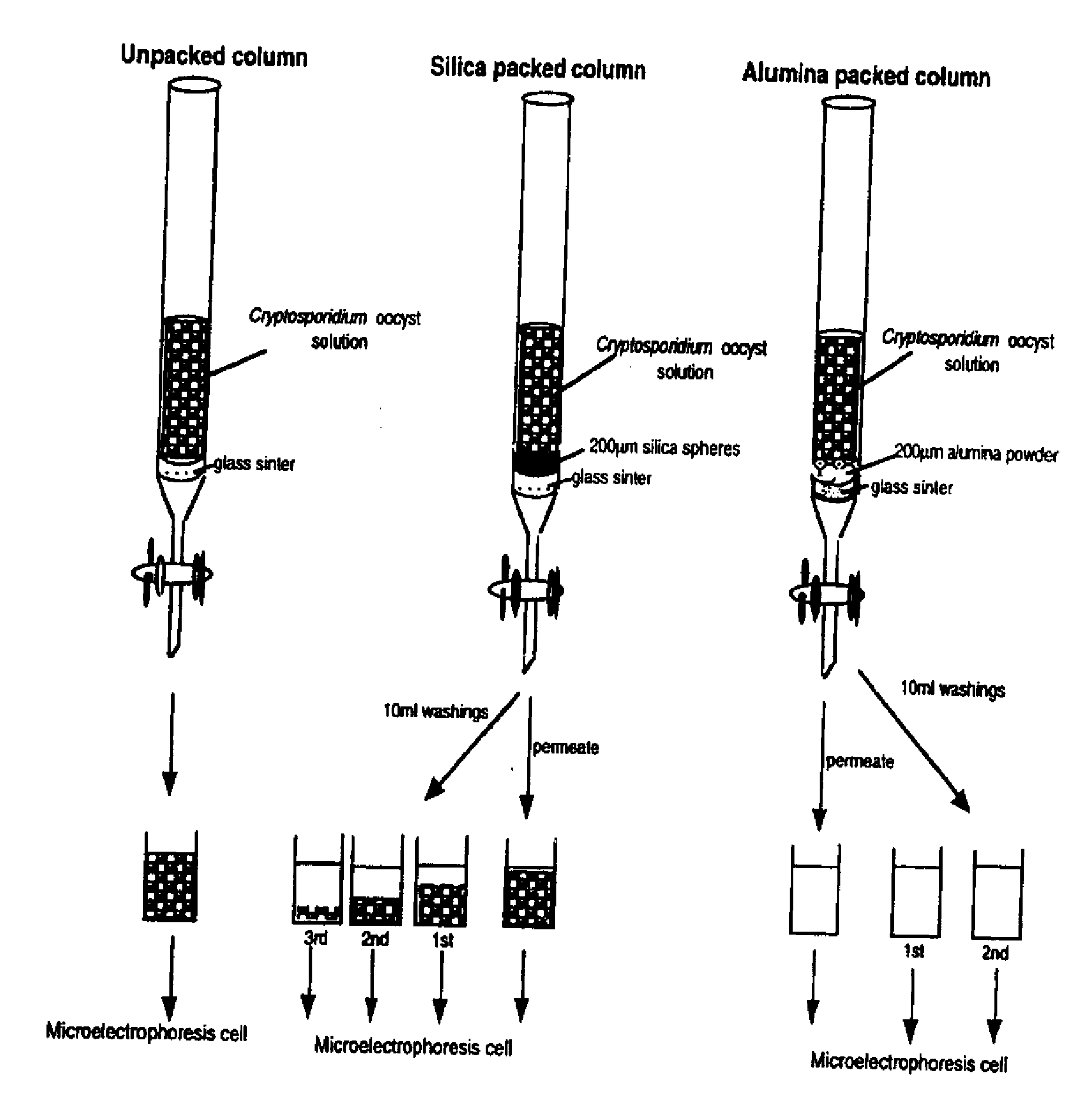

Column Separators

[0069] A glass chromatography column (28 mm O.D) containing a #3 glass sinter was chosen for column separations (see FIG. 5). In order to ensure the pores of the glass sinter were large enough to allow the Cryptosporidium oocysts through, a 10 ml sample of 1.5×106 oocysts / ml was passed through the glass sinter of the unpacked column.

[0070] The column permeate was collected and transferred to a microelectrophoresis cell and examined using dark field illumination. At the first stationary level about 125 negatively charged particles (oocysts) were observed. This demonstrated that oocysts could easily pass through the glass sinter.

(2.2) Silica Blank

[0071] The silica Ballotini) spheres were fractionated to a size approx 200 μm in diameter as described earlier. The glass column was packed to a depth of 5 mm with the fractionated large Ballotini spheres. 10 ml of distilled water was allowed to percolate through the packed column and the permeate collected. The permeat...

example 3

[0078] To investigate the various rapid rehydroxylation methods the alumina was heated to 610° C. and the powder treated either with H2O2 or NaOH. The powder was then dried in the oven at 110° C. to remove surface water and tested to see whether the powder fines floated or sank. The method developed involved taking a sample of the powder on the end of a spatula and then as approach the surfaces at an angle of 45° the powder was slowly moved through the air / water interface, the spatula was then slowly withdrawn and if the powder was not fully hydroxylated the powdered fines floated, whereas if the powder was fully hydroxylated in appeared to be wetted and ran off the end of the spatula.

NaOH Treated Alumina.

[0079] We tested the powders treated with 1×10−5, 5×10−4 and 1×10−2M NaOH for an hour. The powders treated with 1×10−5, 5×10−4 floated whereas the 1×10−2 M NaOH treated sample sank indicating that the particles of alumina had become hydrophilic.

H2O2 Treated Alumina.

[0080] We ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pka | aaaaa | aaaaa |

| negative surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com