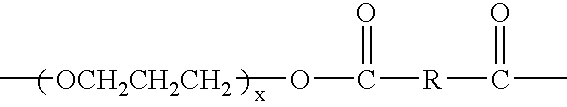

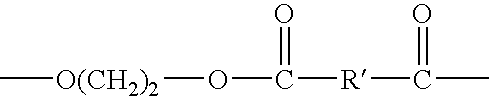

Polyether ester elastomer composition

a technology of polyether ester and elastomer, which is applied in the field of thermoplastic polyether ester elastomers, can solve the problems of unmodified polyether ester comprising polytrimethylene ether terephthalate soft segment and polyethylene terephthalate hard segment that is unsuitable for most injection molding applications, and is difficult to pelletize or flake polymer, etc., to achieve fast crystallization rate, effective utilization of polymer, and rapid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0121]This example illustrates the preparation of a polyether ester with the same stoichiometry as that prepared in Comparative Example 1, but in this case including trisodium phosphate nucleating agent.

[0122]A 25 gallon autoclave was charged with 33.2 lbs of dimethyl terephthalate, 30 lbs of PO3G (Mn of 2440), 14 lbs of ethylene glycol, 2 lbs of 1,4-butanediol, 80 g of ETHANOX® 330 antioxidant, 12 g of TYZOR® TPT as catalyst, and 136 g of trisodium phosphate as nucleating agent. The temperature was raised to 215° C., and methanol generated was removed with a nitrogen flush by distillation as a liquid condensate. The temperature was held at 210° C. for about 1.5 hours until no more methanol evolved indicating the end of the transesterification reaction.

[0123]The temperature was then raised to 250° C. and held at that temperature at a pressure of 0.3 mm Hg for 2.5 hours. The polymer was extruded into ribbons and converted into flakes.

example 2

[0127]This example illustrates the preparation of a polyether ester with the same stoichiometry as that prepared in Comparative Example 2 but including trisodium phosphate nucleating agent.

[0128]A 250 ml three-necked flask was charged with 42.1 g of dimethyl terephthalate, 29.3 g of PO3G (Mn of 1770), 20 g of ethylene glycol, 0.15 g of IRGANOX® 1098 antioxidant, 25 mg of TYZOR® TPT catalyst, and 0.36 g of trisodium phosphate (2100 ppm of sodium based on the final polymer) as nucleating agent. The temperature was raised to 215° C. under nitrogen, and the methanol generated was removed as a liquid condensate by distillation. The temperature was held at 210° C. for about 1.5 hours until no more methanol evolved, indicating the end of transesterification reaction.

[0129]The temperature was raised to 250° C. and held at that temperature at a pressure of 0.2 mm Hg for 2 hours. Then the reaction was stopped by removal of the heat and vacuum, and the polymer was collected.

example 3

[0130]A polyether ester was prepared as described in Example 2 except that the amount of trisodium phosphate used was 0.26 g (corresponding to 1700 ppm of sodium based on the final polymer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com