Method For Producing Metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

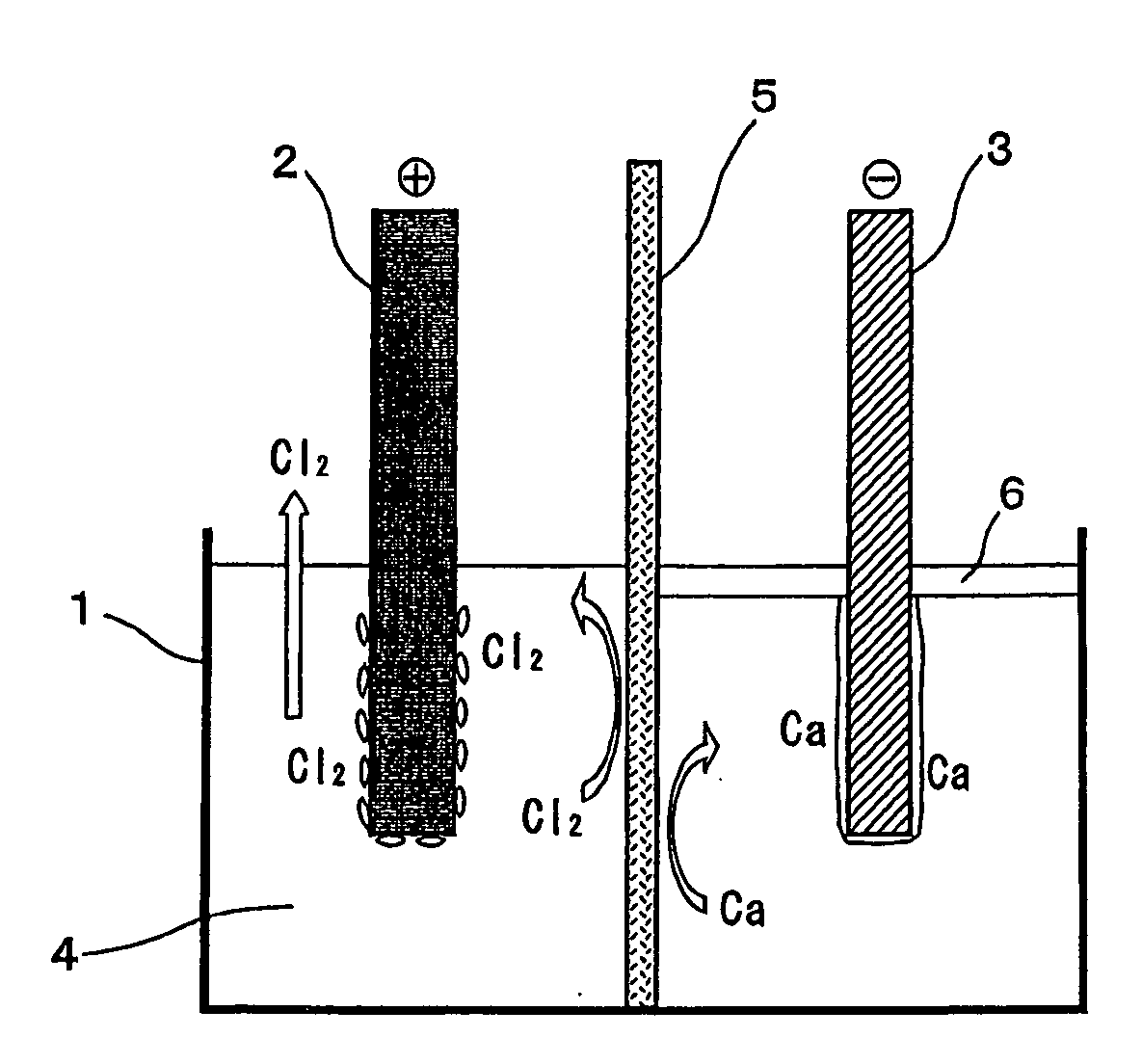

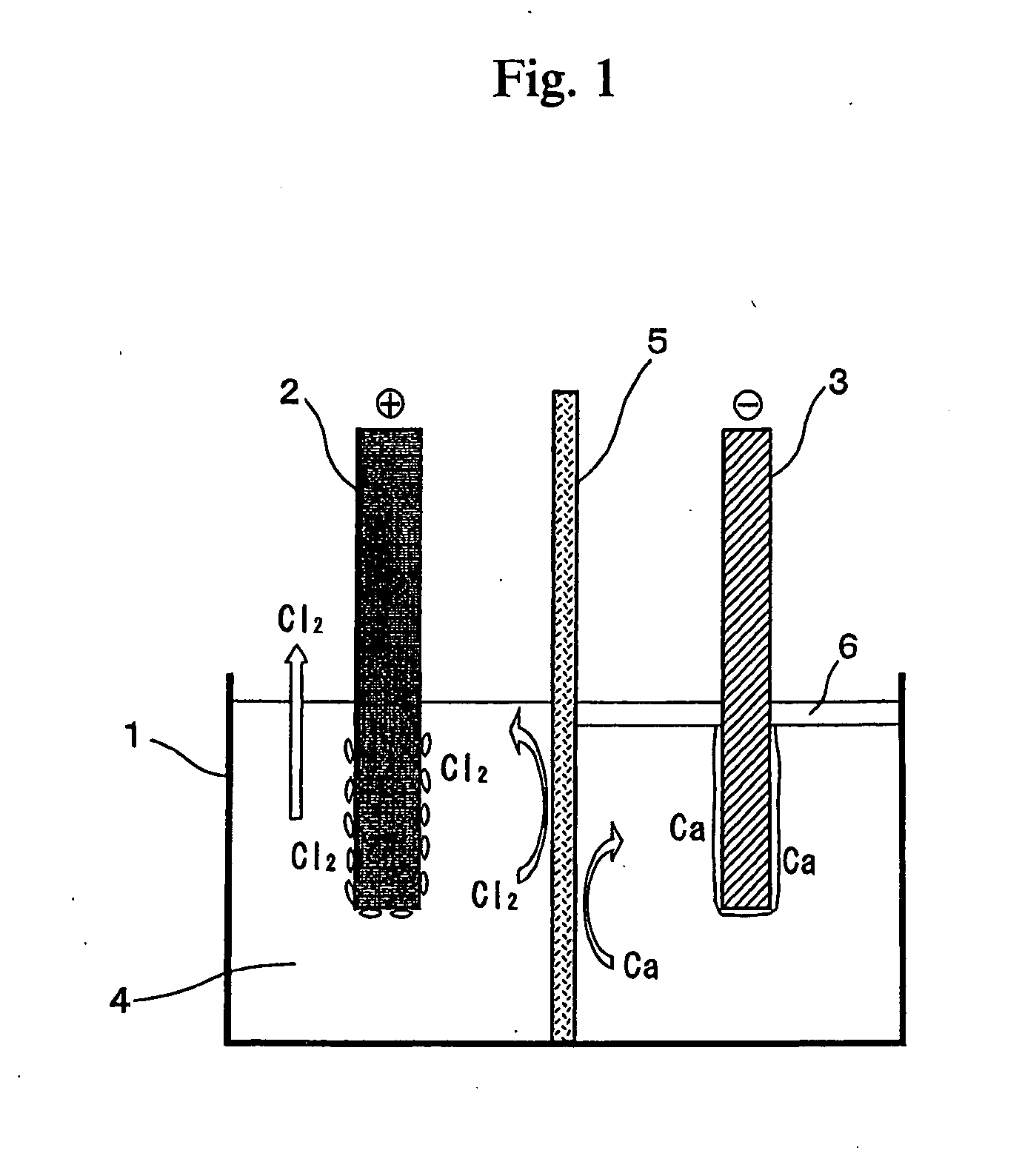

[0056]An electrolytic cell was prepared applying metallic titanium as the cathode and graphite as the anode, calcium chloride mixed with 25 mole percent of potassium chloride was used as the electrolytic bath, and the bath temperature was adjusted to 700-750° C. (in certain tests, 850° C.).

[0057]A diaphragm was disposed between the cathode and anode, and electrolysis was carried out for 300 minutes. The diaphragm was constituted with a porous ceramic body obtained by firing an yttria-containing material under varied conditions. The purity of yttria, the porosity, pore diameter and thickness of the ceramic body obtained, and the current density on the occasion of electrolysis are shown in Table 1.

[0058]As the yttria-containing material, employed was high-purity yttria (≧99.9 mass %) whose content of impurities (Fe2O3, SiO2, etc.) resulting from the production process was less than 0.1 mass %. For investigating the influence of the yttria purity, materials being low in yttria purity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com