Seamless steel tube for use as a steel catenary riser in the touch down zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 1

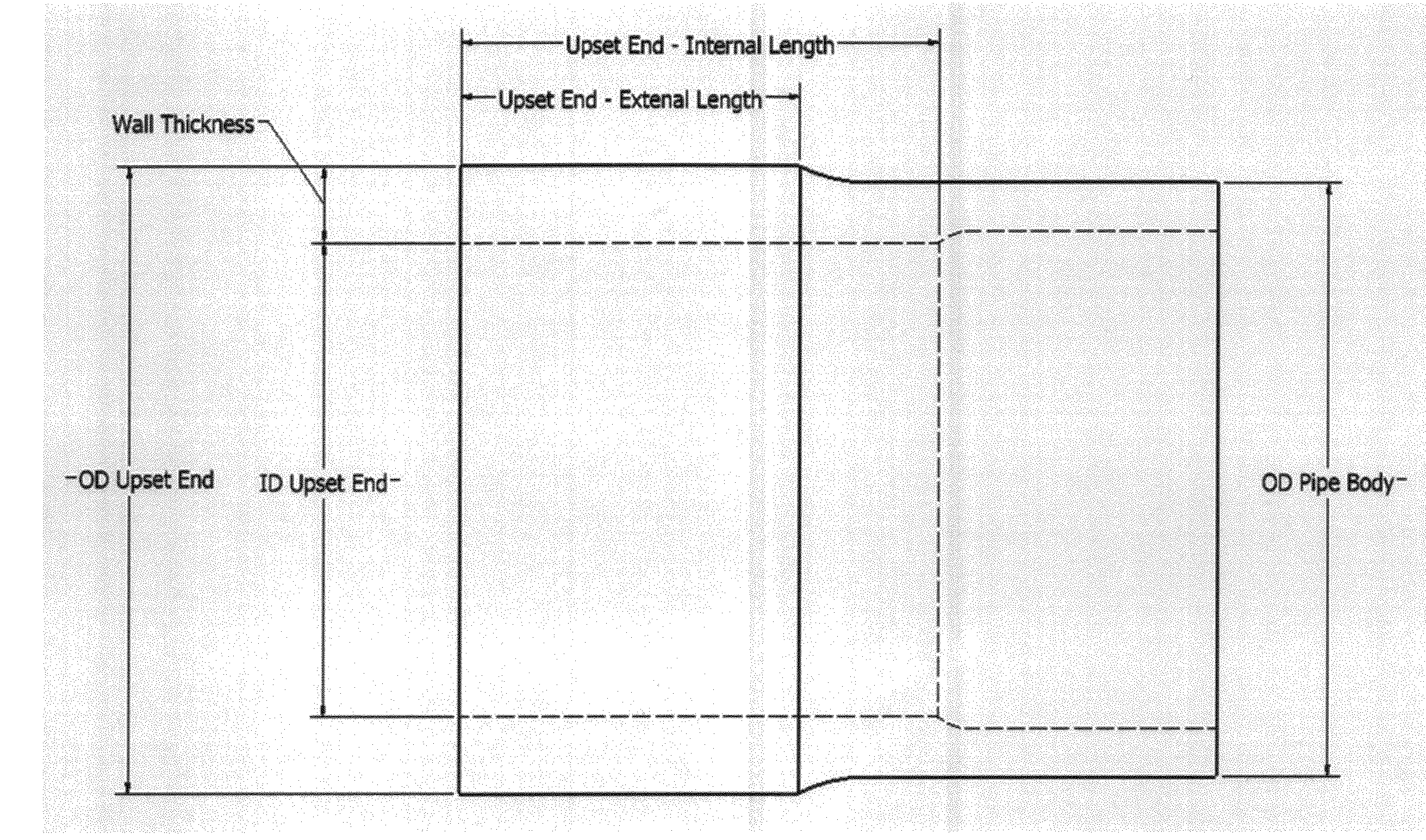

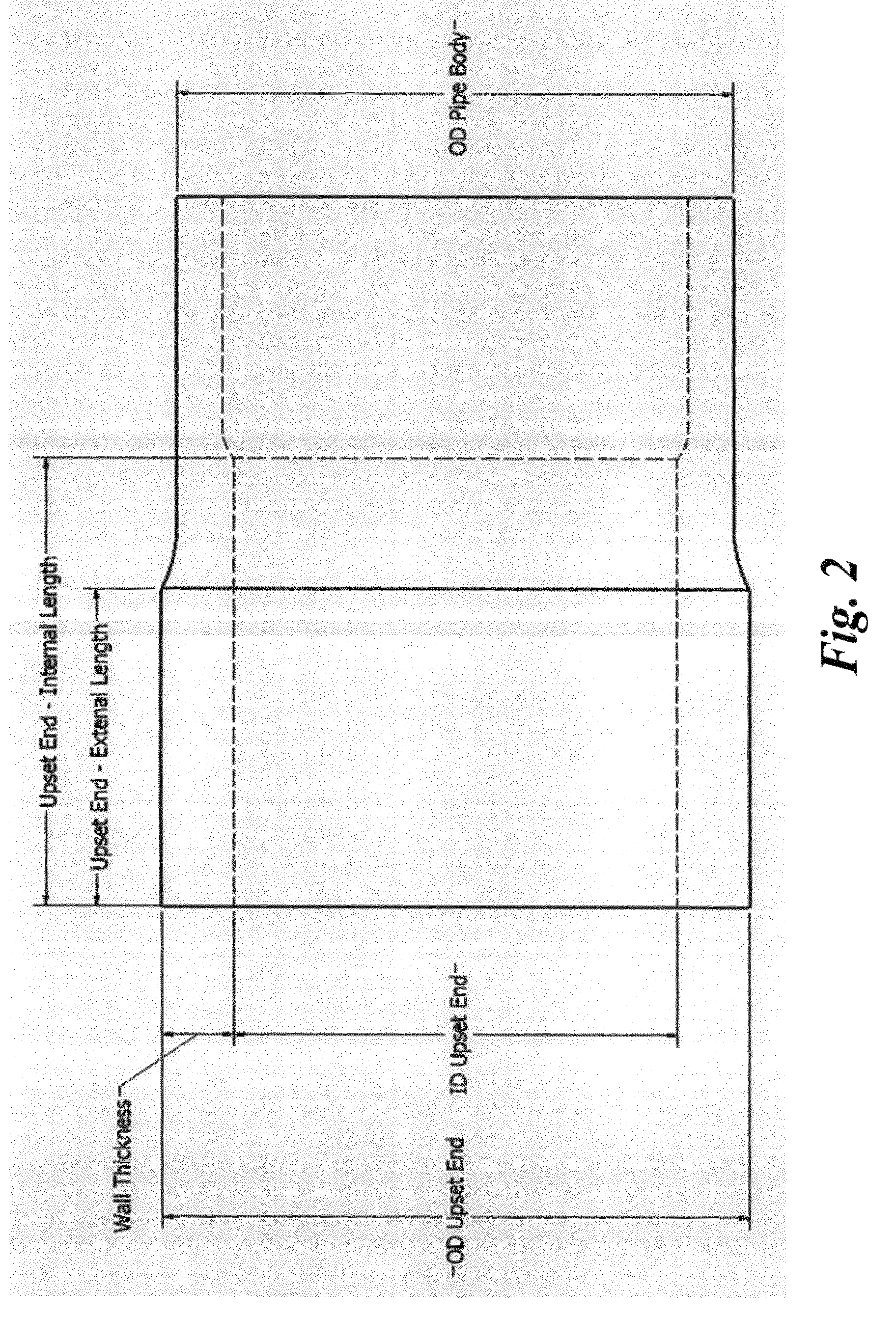

[0069] 273.1 mm OD by 22.0 mm WT Pipe body, 28 mm WT as machined Upset Ends and 35 mm as upset ends, steel grade X65 for non-sour service application (10.75″×0.866″)

case 2

[0070] 273.1 mm OD by 31.8 mm WT Pipe body, 45 mm WT as machined Upset Ends and 53 mm as upset ends, steel grade X65 for sour service application (10.75″×1.250″).

[0071]Case (1) Upset SCR TDZ 10.75″ OD×0.866″ WT X65 Non Sour Service

[0072]FIGS. 4(a) and (b) and 5 show the Yield Strength (YS), Ultimate Tensile Strength (UTS) and the YS / UTS ratio evaluated at room temperature for quenched and tempered material. Longitudinal and transverse round specimens taken from sections representing the Upset End, Slope Transition and Pipe Body are tested in two quadrants, 0° and 180°. All specimens are standard round except by those from the pipe body in the transverse direction which are sub-size round. FIGS. 4(a) and (b) show all the YS and UTS values obtained from the tensile test in the longitudinal and transverse directions, respectively.

[0073]FIGS. 4(a) and (b) show that all Yield Strength values obtained are above 65,000 psi minimum and do not exceed the 80,000 psi maximum. All the Ultimate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com