Treatment of Pulp

a technology of pulp and pulp pulp, applied in the field of pulp treatment, can solve the problems of large quantity of bleaching agent, increased production cost, inefficient use of large amount of bleaching agent, etc., and achieve the effect of reducing waste streams, reducing production costs, and maintaining the balance of the plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

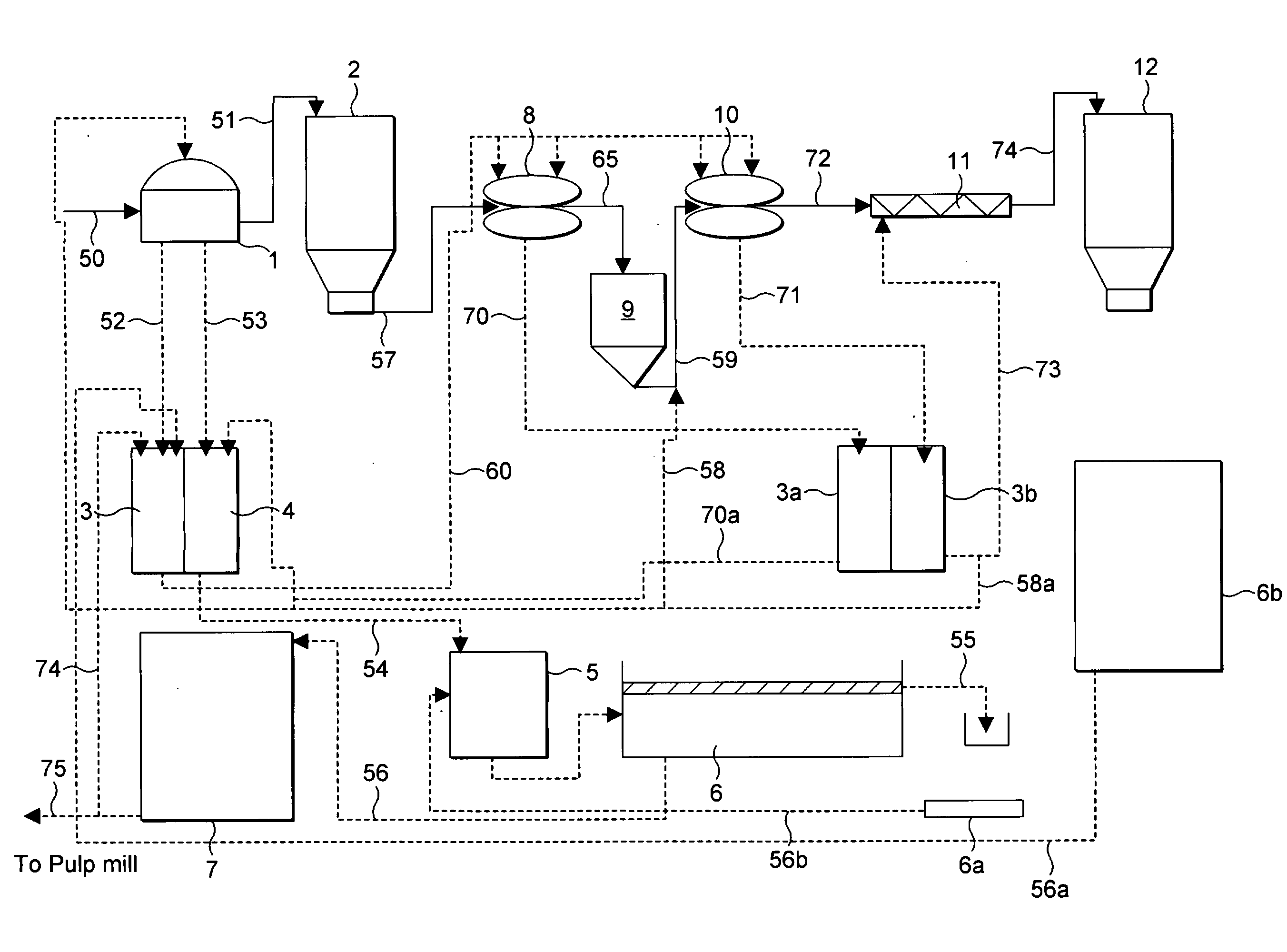

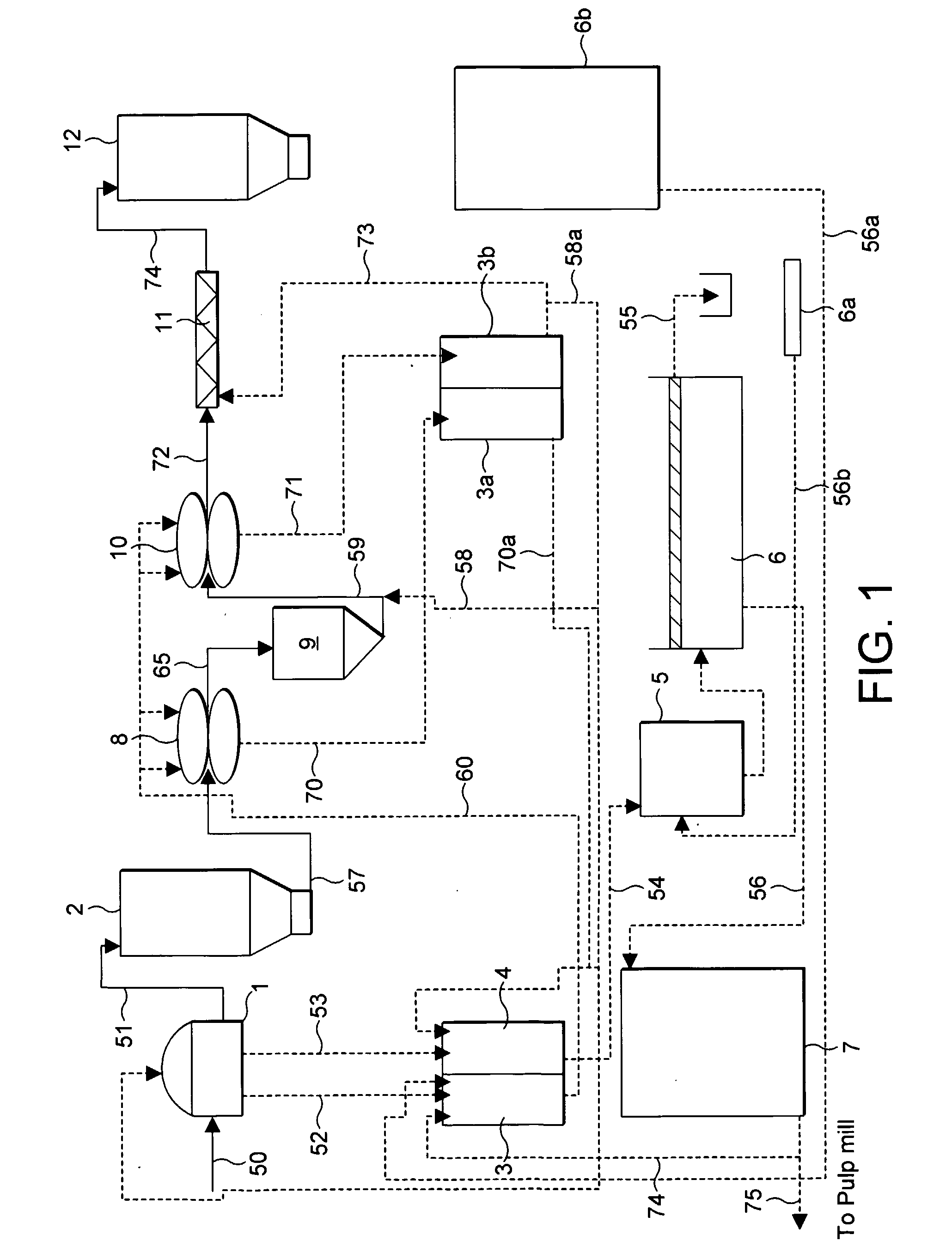

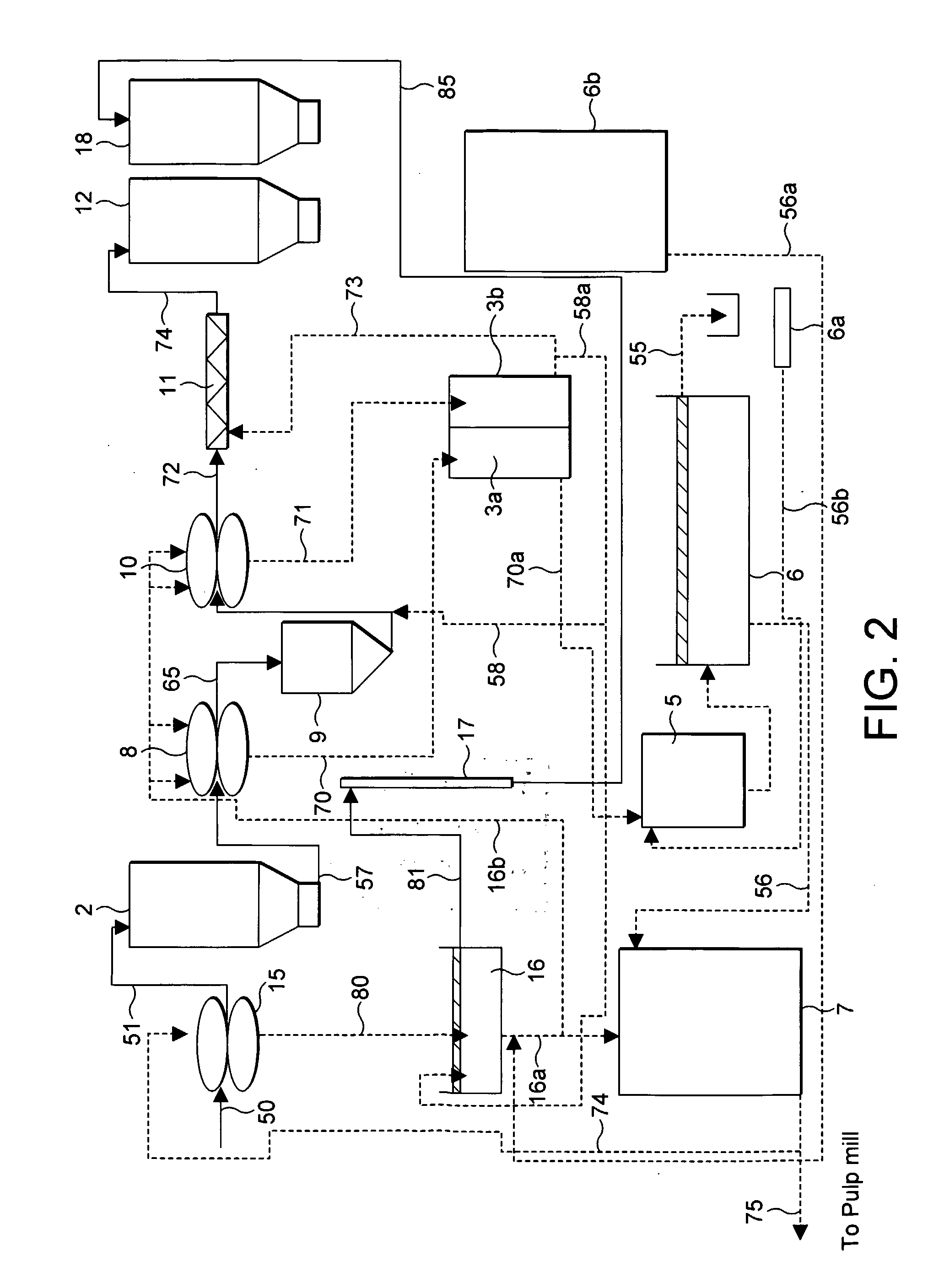

Image

Examples

examples

Test Methods

Brightness

[0057]The ISO brightness of coated paper was measured by means of an Elrepho Datacolour 2000™ brightness meter fitted with a No. 8 filter (457 nm wavelength), according to ISO 2470: 1999 E.

Brightness Cakes

[0058]Brightness cakes or pads were made according to standard methods. More specifically, the pads are formed by taking about 5 g by dry weight of sample and diluting to about 1%. The sample is dewatered on a 15 cm diameter Buchner funnel to give pads of approximately 280 g basis weight. The pads are then pressed on a handsheet press for about 2 minutes, using three standard blotters per pad. The sequence on the press is: 3 blotters; filter paper; sample; metal plate. After pressing, the samples are dried between two fresh blotters on a drying drum with a surface temperature of 80° C. The filter paper is removed from the dry pad and the brightness is measured from each side wherein the top is the side away from the filter paper and filter is the side against ...

example a

Pulp Splitting

[0068]Pulp splitting was carried out using the OptiThick™ device which is commercially available from Metso in Inkeroinen, Finland, under the following conditions:

Speed—600 m / min;

Head Box Feed—40 litres / s;

Head Box Feed Pressure—21 kPa;

Feed Temperature—60° C.;

[0069]Wire—Kraftex CD288 S-39, fabric 3052203.1.

[0070]The properties of the SGW feed and the coarse fraction obtained after pulp splitting are set out in Table 1 below.

TABLE 1B-B-BrightnessCSFMcN +McN +B-McN +B-McNSample(% ISO)(ml)30 (%)50 (%)200 (%)fines (%)SGW feed68.2418.413.927.250.5Coarse62.715919.227.032.821.0fraction

example b

Bleaching of the Coarse Fraction

[0071]The Stone GroundWood (SGW) coarse fraction which was obtained according to Example A above, was pretreated with 0.1 wt % diethylenetriaminepentaacetate (DPTA, available from E.G. Merck) and thickened to 25 wt % solids using a vacuum funnel and centrifuge under standard conditions. A series of chemical doses of hydrogen peroxide was used to bleach 30 g samples in plastic bags. Bleaching was carried out at 70° C. (maintained in a water bath), using 25 wt % solids and a reaction time of 90 minutes. Following this, the samples were acidified to pH 5.5 with H2SO4.

[0072]Brightness cakes of each of the samples obtained were made and the results according to Table 2 were obtained which compare the original feed with the coarse fraction.

TABLE 2ResidualExamplePeroxideNaOHSilicateDTPApHpHperoxideB'nessB'nessNumber(wt %)(wt %)(wt %)(wt %)startfinal(wt %)startfinalFeedSGW11.51.351.20.110.98.80.2168.273.922.01.61.50.110.99.00.6468.277.933.02.12.10.110.89.40.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com