Development of Novel Antibiotic Alternatives

a technology of antibiotic alternatives and antibiotics, applied in the direction of antibacterial agents, peptide/protein ingredients, peptide sources, etc., can solve the problems of not being cost-effective to purify this protein, and death of cellular targeted bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Colicin Production, Purification, and Efficacy

Colicin Production and Purification

[0073]Colicin producing E. coli strains, obtained from the National Collection of Type Cultures (Public Health Laboratory Service, London, England), were inoculated into Luria Broth (LB) to a starting OD600˜0.1, and incubated with shaking at 37° C. When the cultures reached an OD600=0.9 colicin production was induced by the addition of 0.2 U Mitomycin C (Sigma) / mL culture. The cell free supernatant was obtained by centrifugation 5.5 h later, and concentrated by ultrafiltration in a stir-cell apparatus (Amicon, Millipore, Bedford, Mass.) across a regenerated cellulose membrane with a 30 kDa cut-off (Millipore). The concentrated sample was then desalted against 10 mM Tris-Cl, pH 8 and purified by ion exchange chromatography. The desalted samples were applied to a column containing Q Sepharose (Amersham Biosciences, Piscataway N.J.), equilibrated with 10 mM Tris-Cl, pH 8.0 (equilibration buffer), and exhau...

example 2

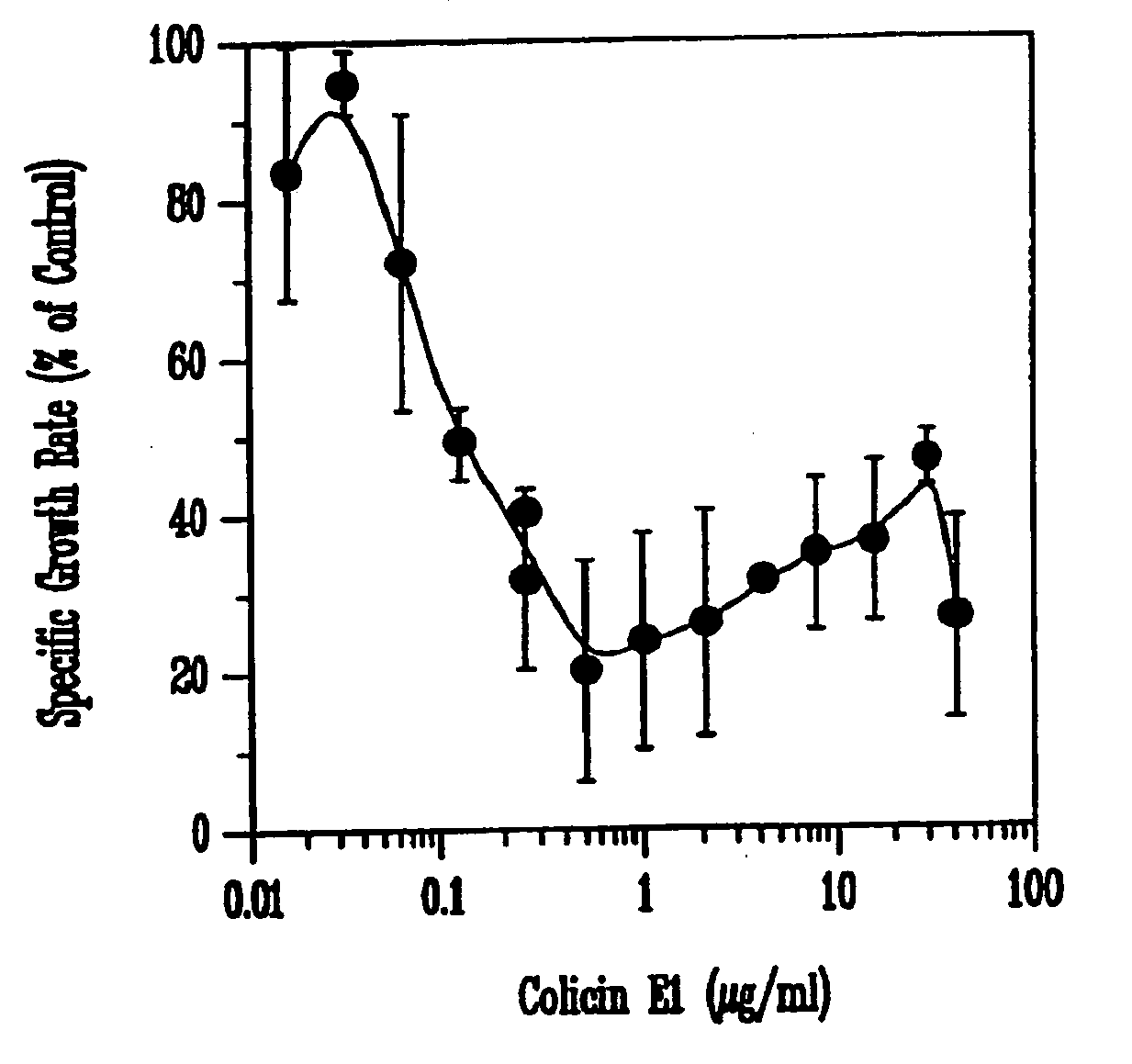

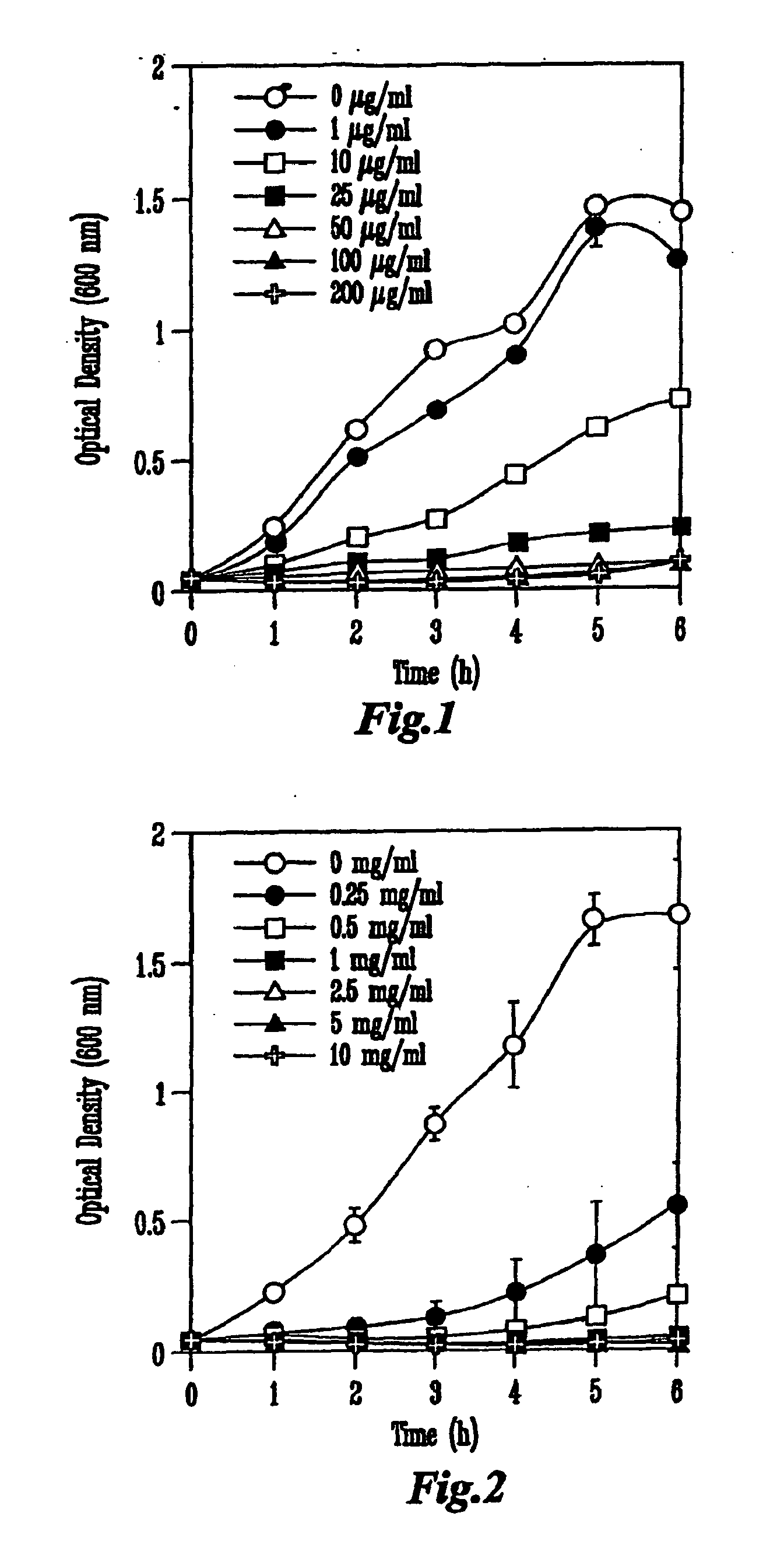

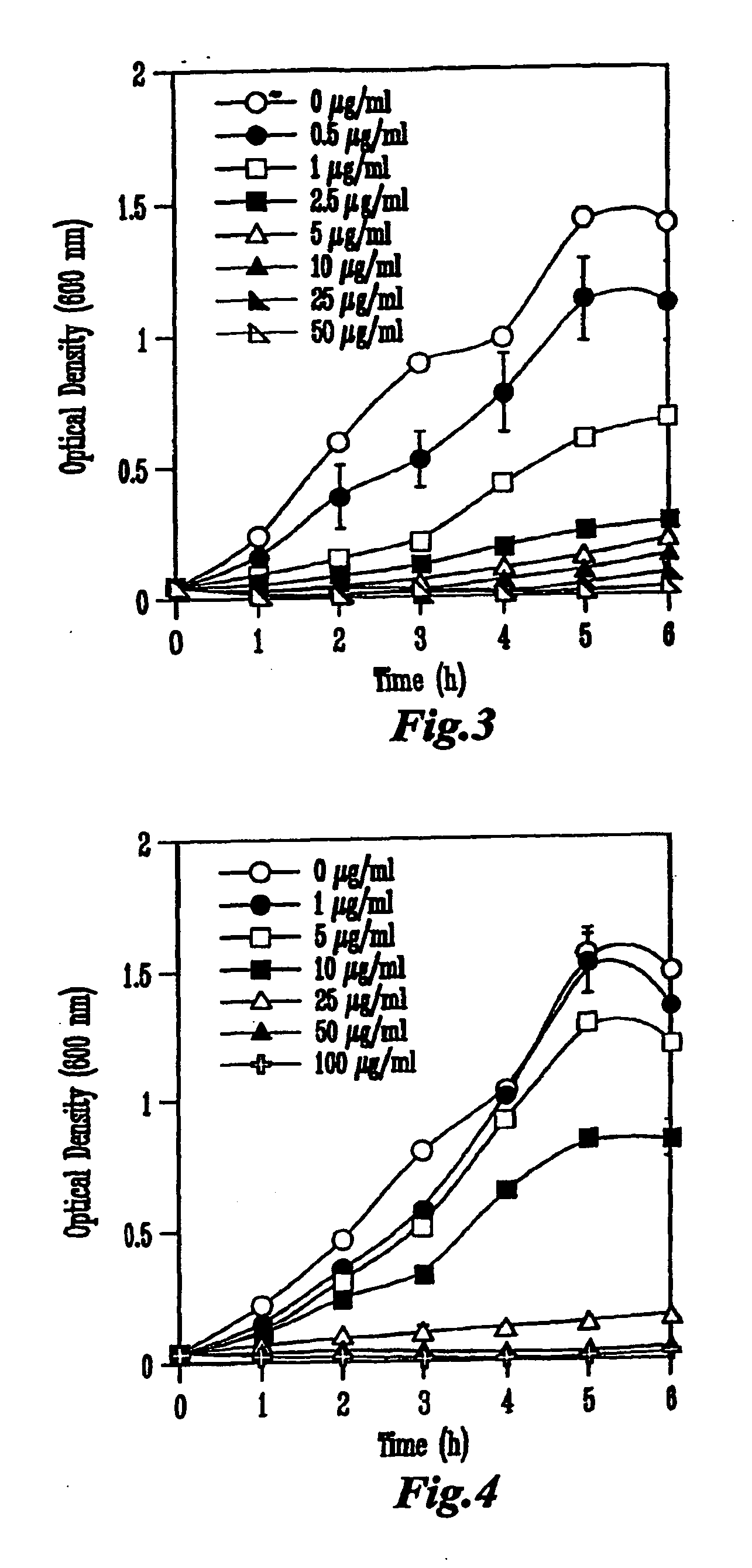

Inhibition of Growth of Escherichia coli 0157:H7 In Vitro

Materials and Methods

Colicin Production and Purification

[0080]Each colicin was produced from a specific colicin-producing E. coli K-12 strain (NC50129-01 containing plasmid pColA-CA31, NC50132-01 containing plasmid pColE1-K53, and NC50145-01 containing plasmid pColN-284) obtained from the National Collection of Type Cultures (Public Health Laboratory Service, London, UK). Cultures were inoculated into Luria-Bertani (LB) broth to an initial optical density of 600 nm (OD600) of approximately 0.1 and incubated in a shaker at 37° C. When the cultures reached OD600=0.9, colicin production was induced by the addition of 0.2 U of mitomycin C per ml of culture (Sigma Chemicals, St. Louis, Mo.). The cell-free supernatant was obtained by centrifugation 5.5 h later and concentrated by ultrafiltration in a stir-cell apparatus (Amicon, Millipore, Bedford, Mass.) across a regenerated cellulose membrane with a 30-kDa cut-off (Millipore). The...

example 3

Recombinant Expression of Colicins

[0092]Yeast expression vectors were constructed and verified by sequencing for Colicin A, B, E1, 1a, and N. Expression and secretion of an active Colicin A by Pichia pastoris were obtained, and confirmed by spot testing of cell-free supernatant of Pichia pastoris expressing Colicin A against E. coli DH5α. In the functional assay (spot testing) 110 μl of cell-free supernatant from transformed P. pastoris showed a clearing of approximately the same size as 1 μg of purified Colicin A from E. coli. Spot 2 showed 1 μl of cell-free supernatant from P. pastoris. Spot 3 showed 5 μl of cell-free supernatant from P. pastoris, and spot 4 showed 10 μl of cell-free supernatant from P. pastoris.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com