Toughened Cyanoacrylate Compositions

a technology of cyanoacrylate composition and composition, which is applied in the direction of adhesive process, cellulose adhesive, lamination, etc., can solve the problems of reducing the strength of cyanoacrylate, so as to improve the strength of side impact and fracture toughness, improve the shear strength, and improve the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

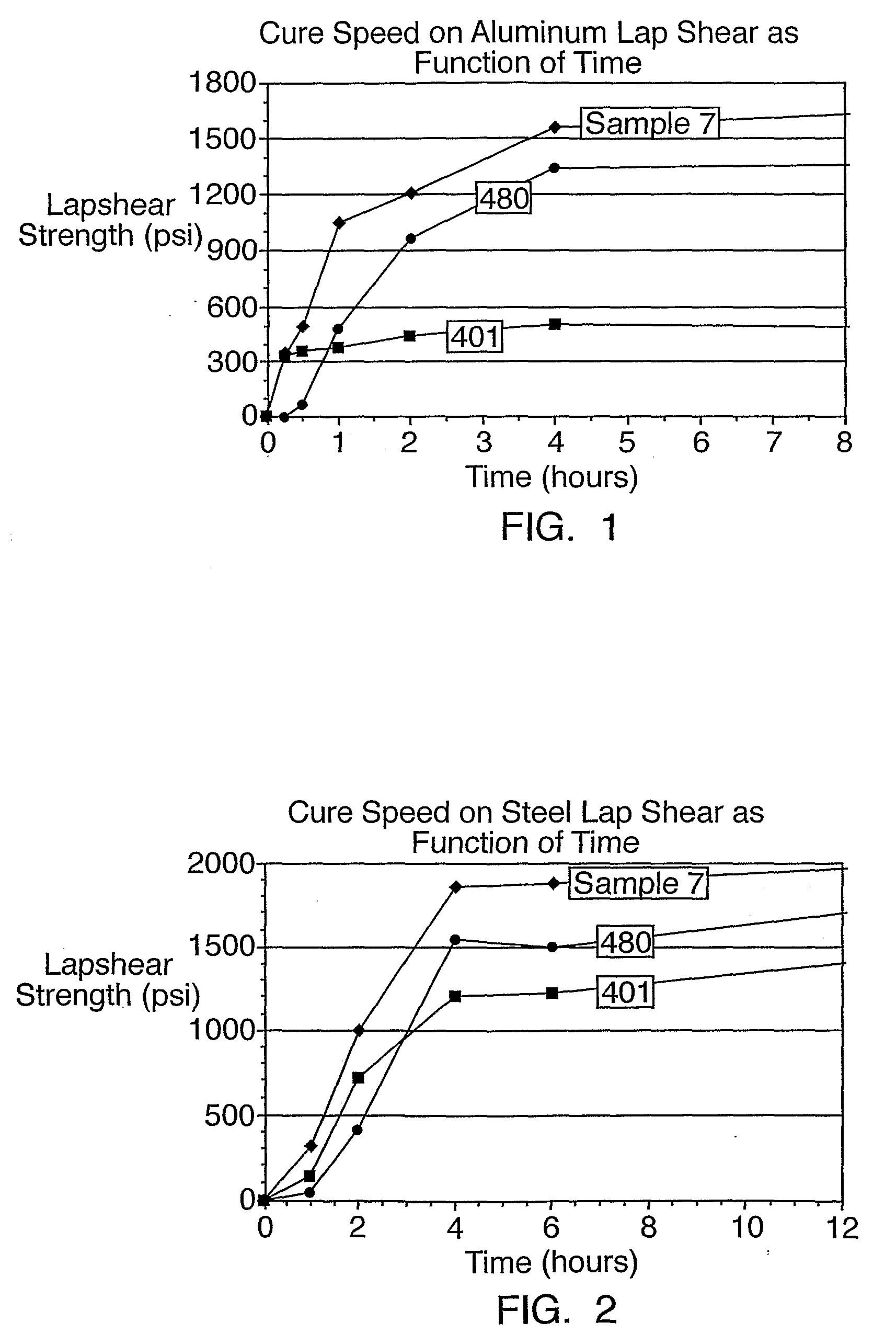

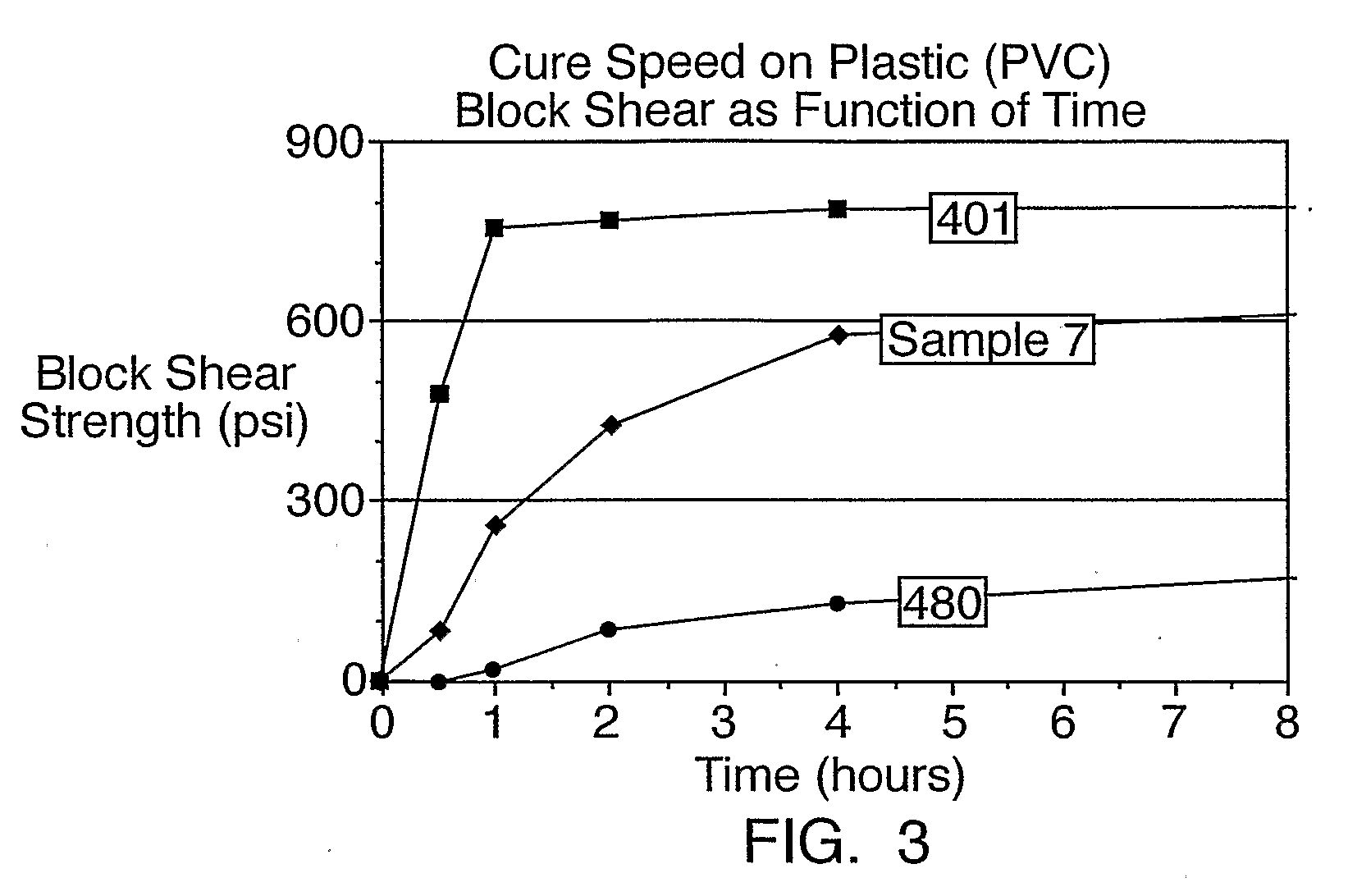

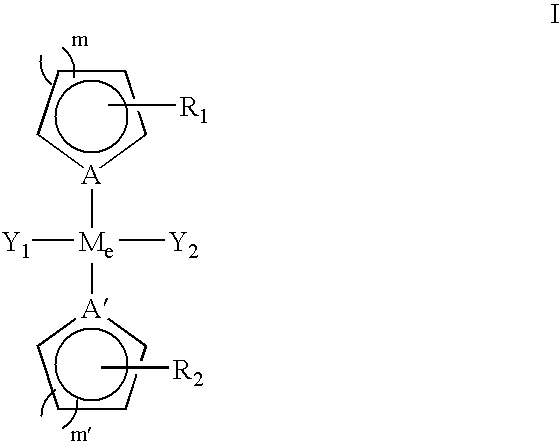

[0075]A number of samples were evaluated for their fixture speeds on a variety of substrates and shelf lives under accelerated aging conditions. The samples evaluated included LOCTITE BLACK MAX 380, LOCTITE 4203, LOCTITE 4204, LOCTITE 4205, LOCTITE BLACK MAX 480, and Sample Nos. 1-9, where the first five samples—labeled as Sample A-E, respectively, are provided for comparative purposes.

[0076]Sample Nos. 1-9 were prepared by mixing together the noted constituents for a sufficient period of time to ensure substantial homogeneity of the constituents. Ordinarily, about 30 minutes should suffice, depending of course on the quantity of the constituents used. The constituents and amounts of LOCTITE BLACK MAX 380 (Sample A), LOCTITE 4203 (Sample B), LOCTITE 4204 (Sample C), LOCTITE 4205 (Sample D), LOCTITE BLACK MAX 480 (Sample E), and Sample Nos. 1, 2 and 3 are given in Tables 1a and 1b; Sample Nos. 4-6 are given in Table 1c; and Sample Nos. 7-9 are given in Table Id.

TABLE 1aComponentSampl...

example 2

[0085]In this example, three VAMAC-brand rubbers, VMX 1012, VCS 5500 and VCS 5520, were dissolved in ethyl cyanoacrylate monomer to formulate cyanoacrylate compositions. The difference in constituents between these two VAMAC-brand rubbers from other commercially available ones (i.e., VAMAC G and VAMAC B-124) is shown below in Table 3. Like VAMAC VCS 5500, VMX 1012 and VCS 5520 are substantially free of processing aids such as the release agents octadecyl amine, complex organic phosphate esters and / or stearic acid, and anti-oxidants, such as substituted diphenyl amine. Unlike VAMAC 5500, VMX 1012 is free of acid cure sites, and VCS 5520 is believed to contain about half the amount of total acid cure sites found in VAMAC G and B-124.

TABLE 3Ingredients usedto make VAMACVMXVCSVCSVAMACVAMACrubber101255205500GB-124EthylenexxXxxMethyl acrylatexxXxxMonomers having—x,x,x,x,carboxylic acid2 wt. %4 wt. %4 wt. %4 wt. %cure sitesInternal release aid———xx(Carbowax / Nargard / Polygaurd)Carbon black——...

example 3

[0088]In this example, two VAMAC-brand rubbers, VMX 1012 and VCS 5520, were dissolved in ethyl cyanoacrylate monomer to formulate cyanoacrylate compositions for a comparison to LOCTITE PRISM 480 (Sample E) as a control. Table 6 below shows the formulation constituents of each sample.

TABLE 6ComponentSample No.TypeIdentity121314CyanoacrylateEthyl-2-CABalanceBalanceBalanceRubber TougheningVAMAC VMX 10128——AgentVAMAC VCS 5520—88StabilizerBF30.0010.00020.0001AcceleratorCrown ether0.2—0.2Other additivesCitric acid0.0050.0050.005Phthalic anhydride0.50.50.5

[0089]Referring below to Table 7, stability of the so formed cyanoacrylate compositions was again determined after accelerated ageing in aluminum tubes at a temperature of 82° C. By using VAMAC VMX 1012 and VCS 5520, the cyanoacrylate compositions were determined to be shelf stable for at least 10 days under the test conditions, which is an improvement over the control. In addition, a faster fixture time was observed for Sample Nos. 12 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| acidic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com