Si-Doped GaAs Single Crystal Ingot and Process for Producing the Same, and Si-Doped GaAs Single Crystal Wafer Produced From Si-Doped GaAs Single Crystal Ingot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

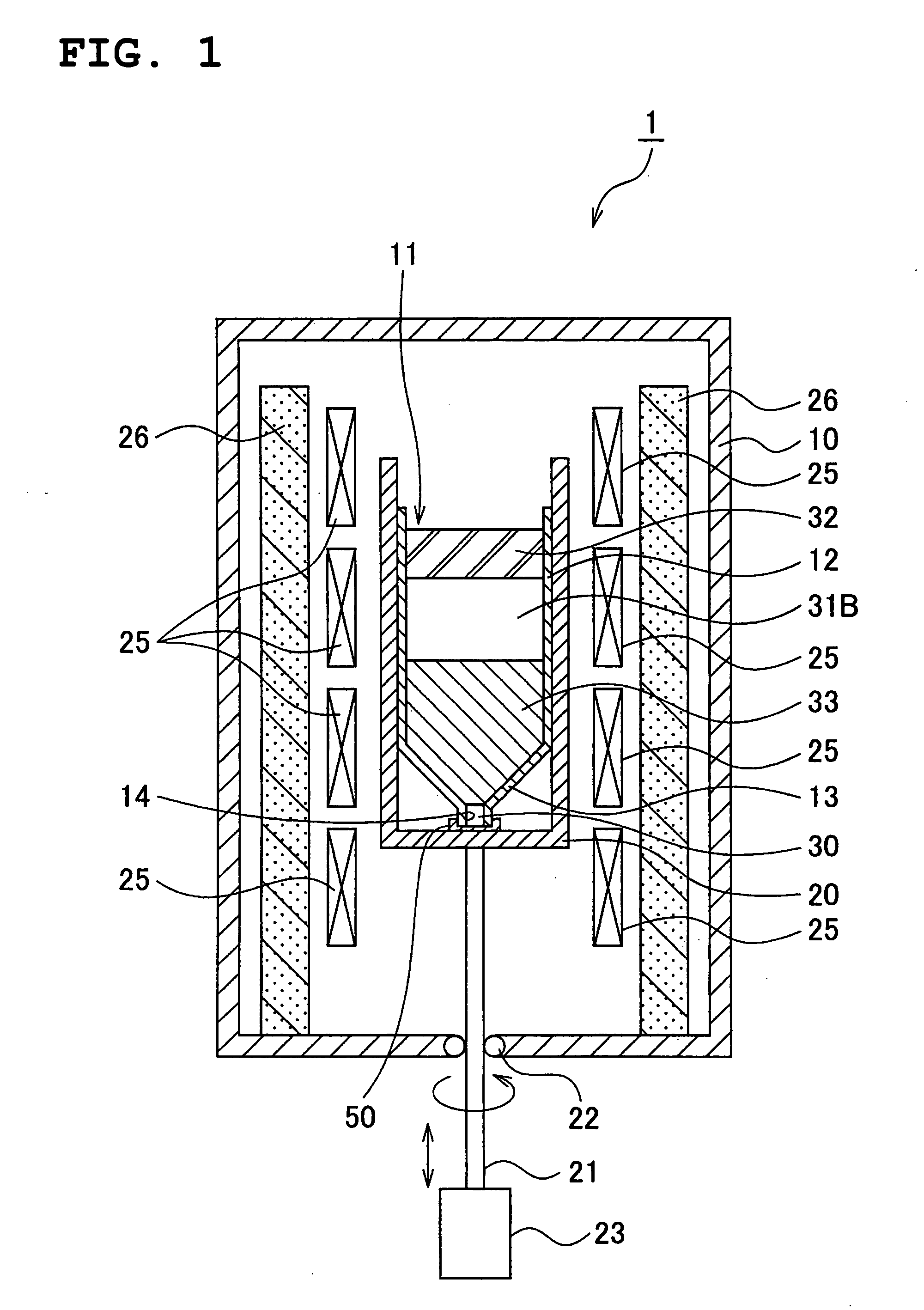

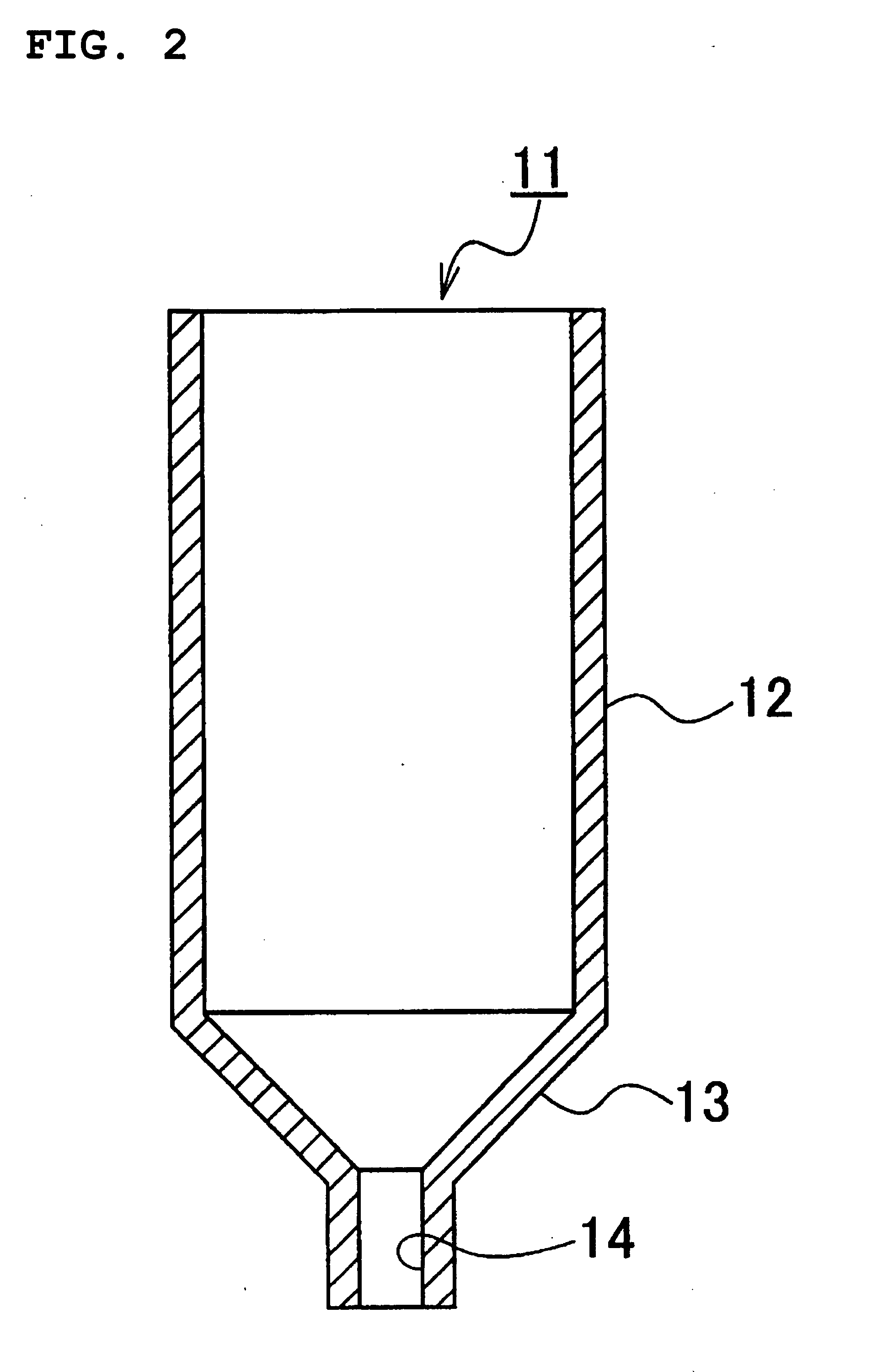

Method used

Image

Examples

example 1

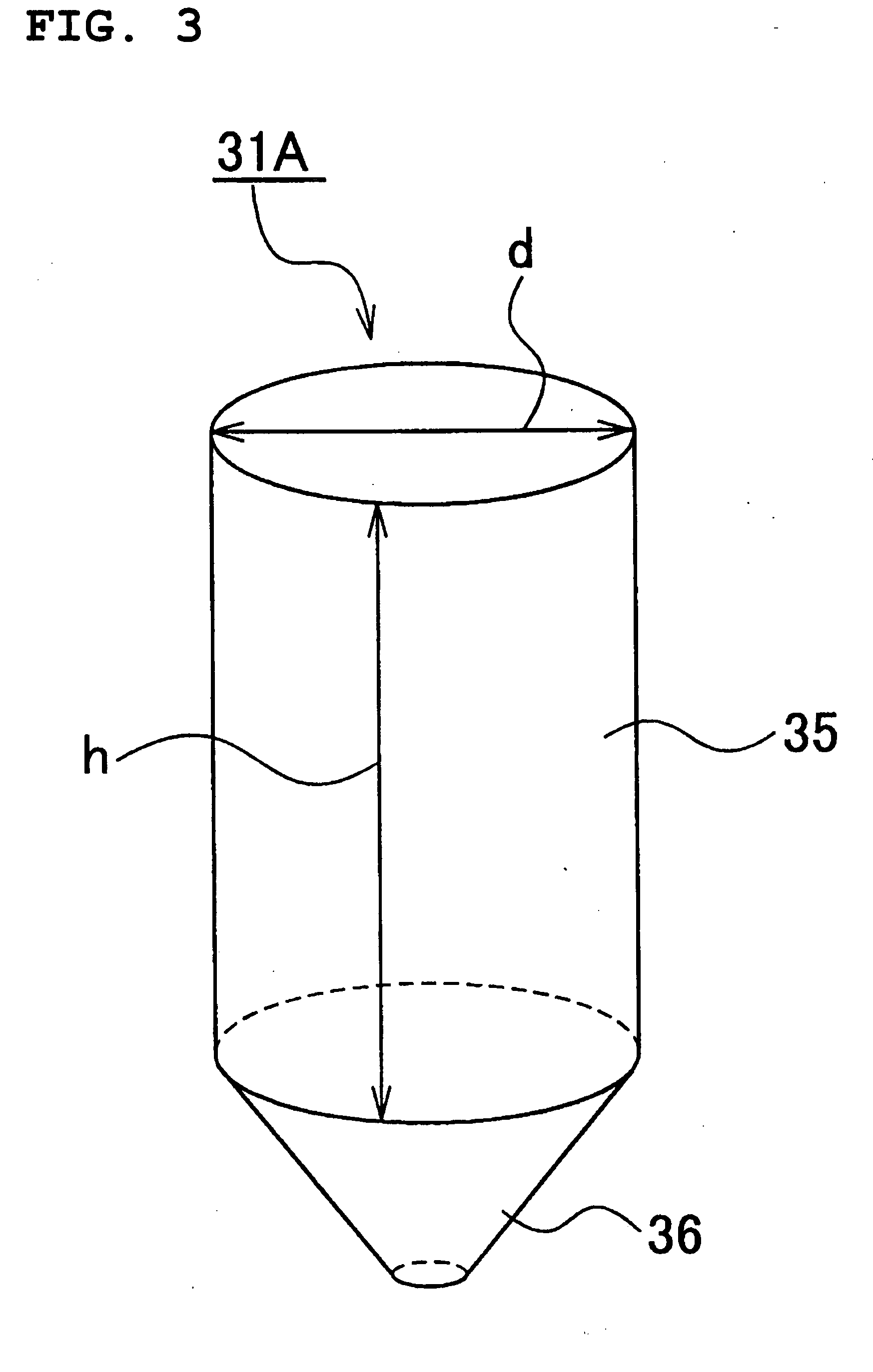

[0095]First, a GaAs compound raw material was synthesized using a separate synthesizing reactor (crucible). The value obtained by dividing the surface area of the synthesized GaAs compound raw material by the surface area of a GaAs single crystal that was grown thereafter using the GaAs compound raw material was 1.05. The synthesized GaAs compound raw material was cut and adjusted, and was furthermore cut into a cylindrical portion and a conical portion. A GaAs compound raw material in the form of a doughnut having the same outside diameter as the cylindrical portion and holding the Si dopant in the inner hole of the doughnut was inserted into the cut portion. The average temperature (ave)° C. was calculated to be 1,298° C. from the temperature profile that was used when the GaAs compound raw material described below was heated, and the insertion position was therefore located below the position that corresponds to this temperature (the temperature of the position was calculated to ...

example 2

[0102]The same apparatus and raw material as those described in example 1 were used, but the Si dopant was placed in a position at 1,327° C. rather than 1,281° C. when the dopant was inserted into the GaAs compound raw material. The same operation as in example 1 was then carried out to produce a GaAs ingot.

[0103]The carrier concentration of the resulting GaAs ingot was 0.9×1018 / cm3 in an area in which the solidification ratio was 0.1 (C0.1), the carrier concentration was 1.1×1018 / cm3 in an area in which the solidification ratio was 0.8 (C0.8), and the ratio C0.8 / C0.1 was 1.22.

[0104]The value of crystallinity evaluated in terms of etch pit density was 10 etch pits / cm2. The value obtained by dividing the fourth power of the B concentration by the cube of the Si concentration was 0.93×1019 / cm3 in the same area.

[0105]The same test as example 2 described above was carried out ten times, and the same measurements were taken. The result was C0.8 / C0.12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com