Copper alloy, copper alloy plate, and process for producing the same

a technology which is applied in the field of copper alloy and copper alloy plate, to achieve the effects of excellent bending property, excellent electric conductivity and high stress relaxation resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

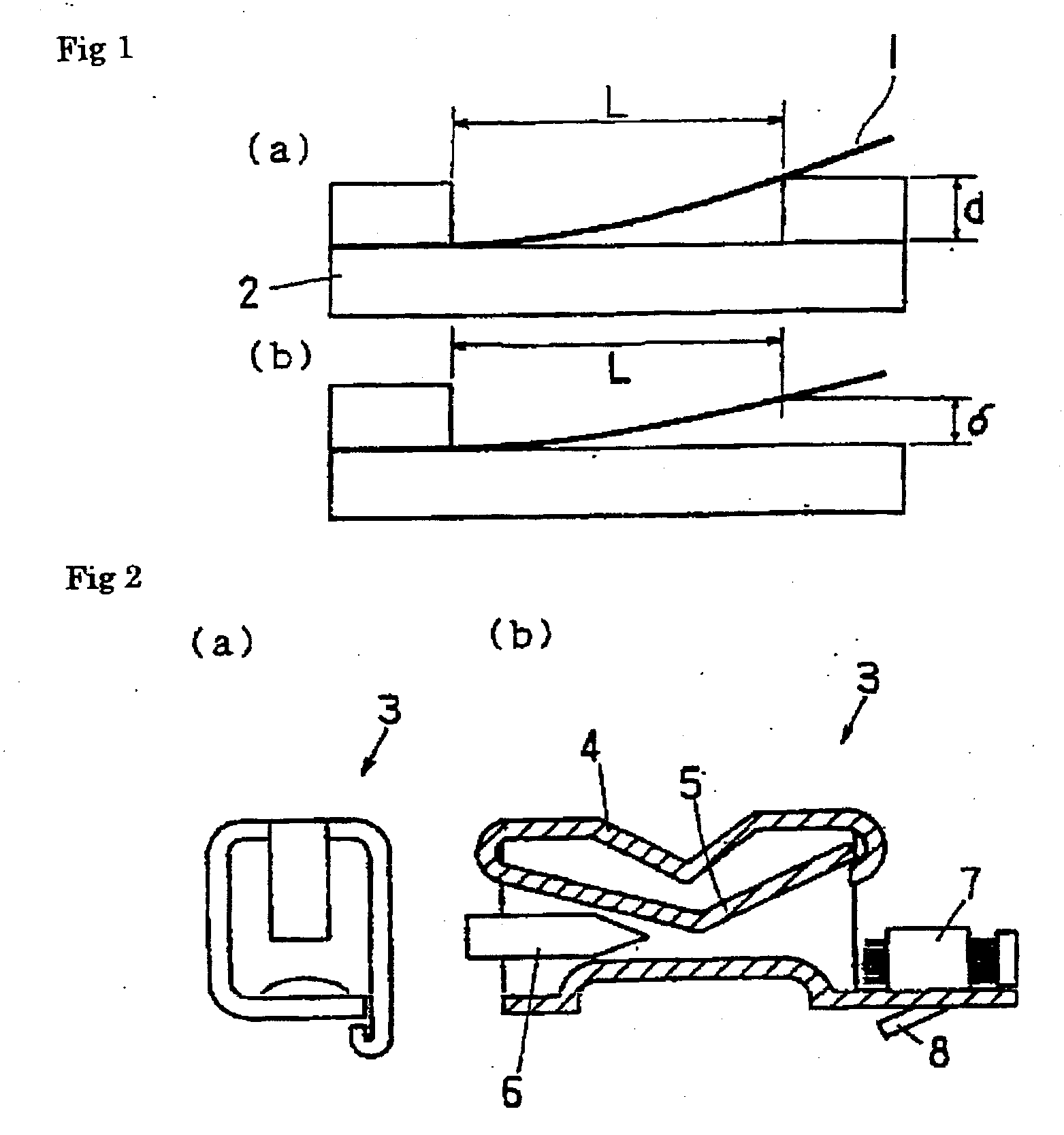

Image

Examples

first embodiment

[0041](Chemical Composition of Copper Alloy)

[0042]First, the chemical composition of the copper alloy according to the present invention will be described. As described above, the premise with respect to the chemical composition of the copper alloy in the present invention is that the copper alloy is a Cu—Ni—Sn—P alloy which can be cast as an ingot in a shaft furnace therefore with high productivity at a greatly reduced cost.

[0043]In addition, to satisfy requirements for connection components such as automotive terminals and automotive connectors, namely, a high stress relaxation resistance along the perpendicular direction to the rolling direction, an excellent bending property, an excellent electric conductivity and an excellent strength, the copper alloy basically contains Ni: 0.1 through 3.0%, Sn: 0.01 through 3.0% and P: 0.01 through 0.3% and is made of remainder copper and inevitable impurities. The amounts of the respective elements expressed in % are all in percents by mass....

second embodiment

[0088]A copper alloy plate according to the second embodiment of the present invention will now be described. The composition of the copper alloy according to the second embodiment of the present invention will be described first.

[0089]Ni is an element which dissolves as solid solutions in the copper alloy, and accordingly enhances the stress relaxation resistance and improves the strength. However, when the Ni content is 0.4% or less, this effect is not promised, but the Ni content exceeding 1.6% will work with P, another additive element present at the same time, and easily precipitate intermetallic compounds, thereby reducing solute Ni and deteriorating the stress relaxation resistance. Hence, the Ni content is set to 0.4 through 1.6%. The range of 0.7 to 0.9% is more desirable.

[0090]Sn is an element which dissolves as solid solutions in the copper alloy and accordingly improves the strength due to work hardening. In the alloy system according to the second embodiment, this eleme...

example 1

[0112]Examples of the present invention will now be described. Various copper alloy thin plates made of Cu—Ni—Sn—P alloys in which the states of Ni compounds in the structures were different were made, and properties such as the strength, the electric conductivity and the stress relaxation resistance were evaluated.

[0113]Describing this more specifically, after making copper alloys whose chemical compositions are as shown in Table 1 each in a coreless furnace, ingot making by semi-continuous casting was performed, and ingots which were 70 mm thick, 200 mm wide and 500 mm long were obtained. The ingots were each rolled under the following common condition, thereby making the copper alloy thin plates. After facing of the surfaces of the ingots, hot rolling was performed, thereby obtaining plates which were 16 mm thick, which was followed by quenching in water from a temperature of 650 degrees Celsius or higher.

TABLE 1Chemical Composition of Copper Alloy Plate (remainder is Cu)Other El...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com