Method of forming a magnetic tunnel junction structure

a magnetic tunnel junction and structure technology, applied in the direction of magnetic field-controlled resistors, digital storage, instruments, etc., can solve the problems of slow etch rate, undesired film loss, corner rounding, etc., to improve the process window for forming mtj structures, reduce erosion and corner rounding, and improve the effect of oxidation and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

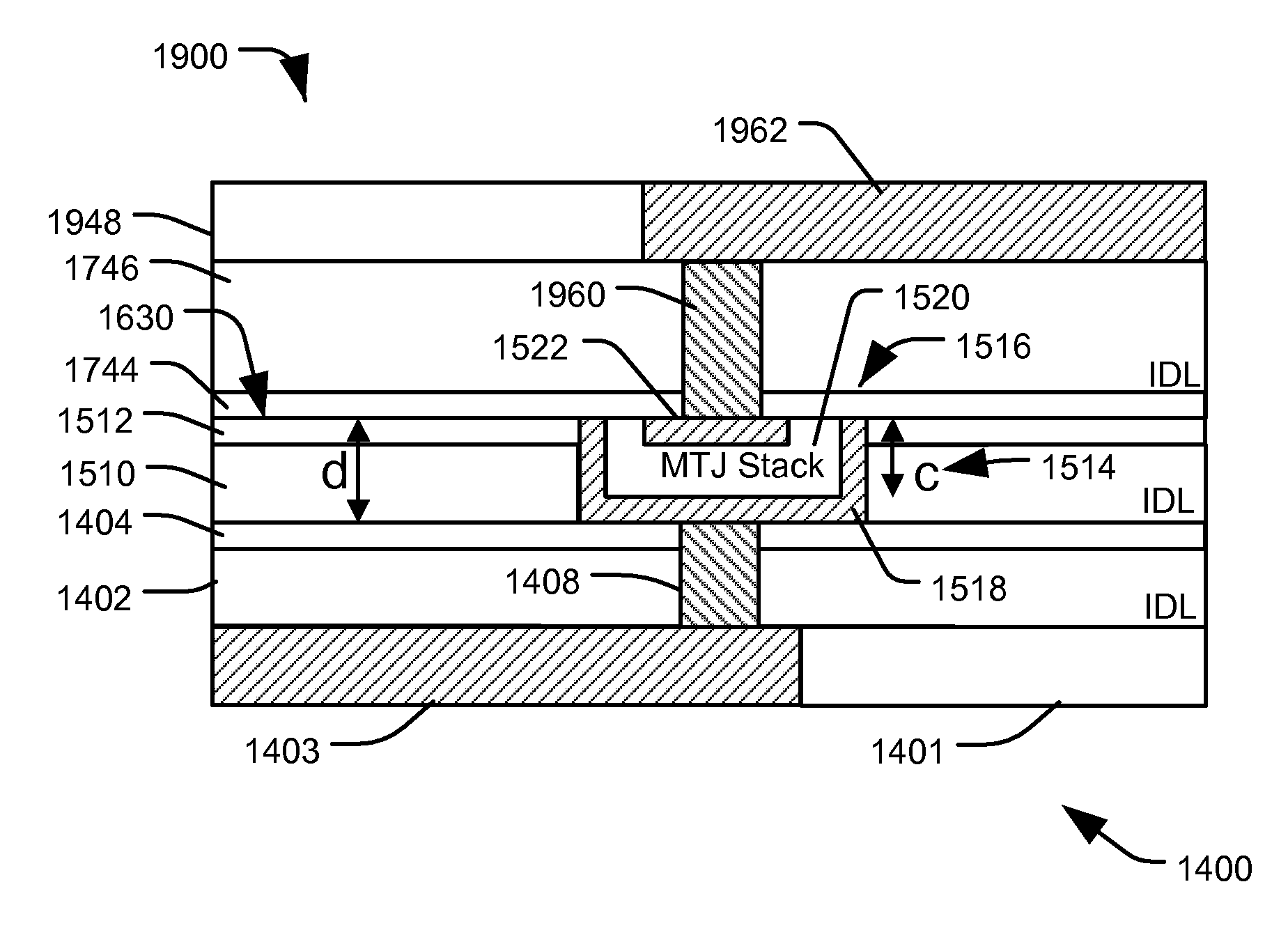

[0034]FIG. 1 is a cross-sectional view of a particular embodiment of a portion of a magnetic tunnel junction (MTJ) cell 100, which may be formed according to the methods and embodiments described with respect to FIGS. 3-24. The MTJ cell 100 includes an MTJ stack 102 having a free layer 104, a tunnel barrier layer 106, a fixed (pinned) layer 108, and an anti-ferromagnetic (AF) layer 126. The MTJ stack 102 is coupled to a bit line 110. Further, the MTJ stack 102 is coupled to a source line 114 via a bottom electrode 116 and a switch 118. A word line 112 is coupled to a control terminal of the switch 118 to selectively activate the switch 118 to allow a write current 124 to flow from the bit line 110 to the source line 114. In the embodiment shown, the fixed layer 108 includes a magnetic domain 122 that has a fixed orientation. The free layer 104 includes a magnetic domain 120, which is programmable via the write current 124. As shown, the write current 124 is adapted to program the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com