De-polluting and self-cleaning epoxy siloxane coating

a technology of epoxy siloxane and coating, applied in the direction of coatings, etc., can solve the problems of reducing durability, difficult to provide coatings with high levels of photocatalyst, and reducing the cost of siloxane type polymers, so as to effectively remove nox compounds from the environment and effectively degrade nox compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

NO Activity Correlated with Total PVC

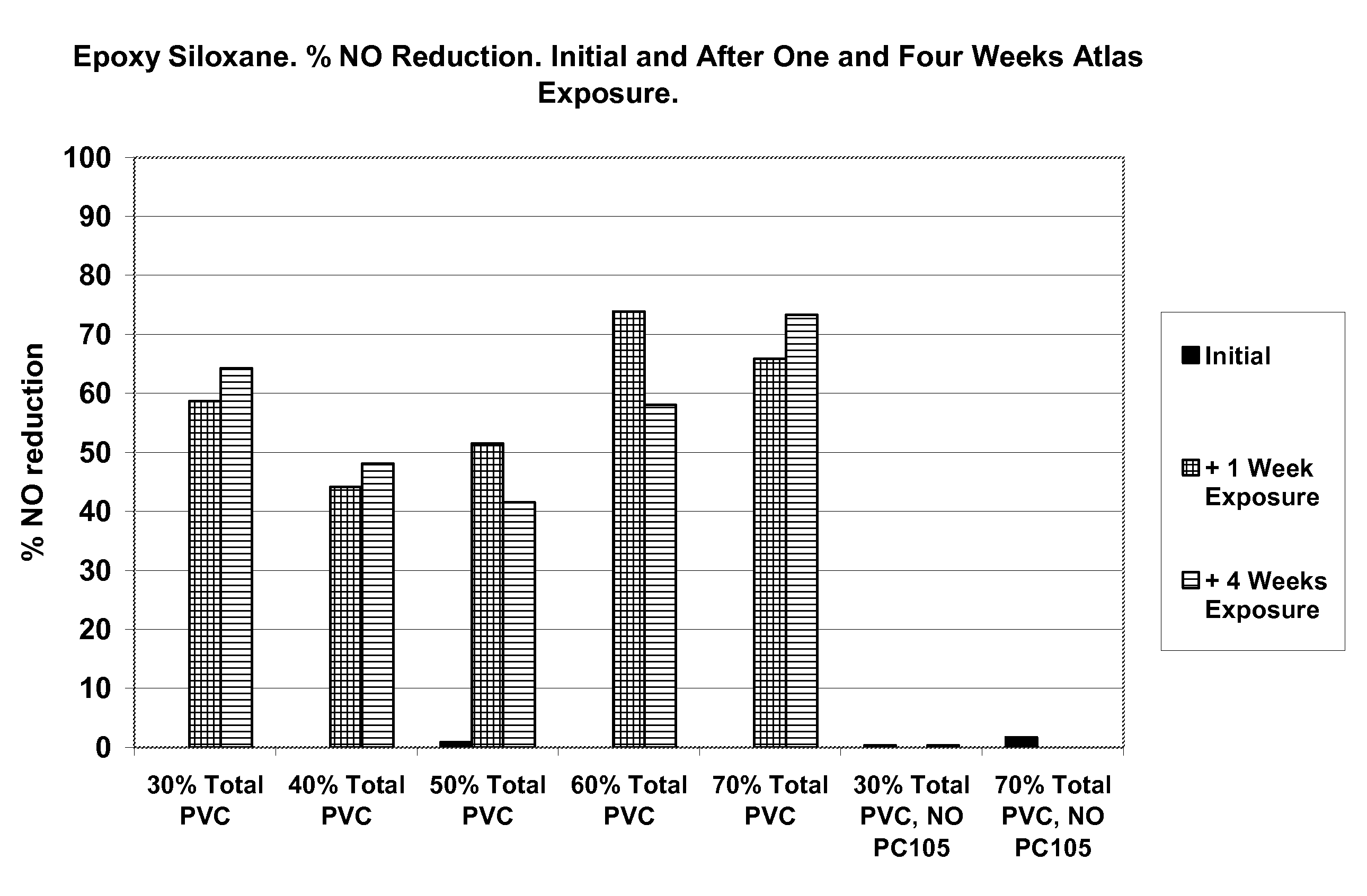

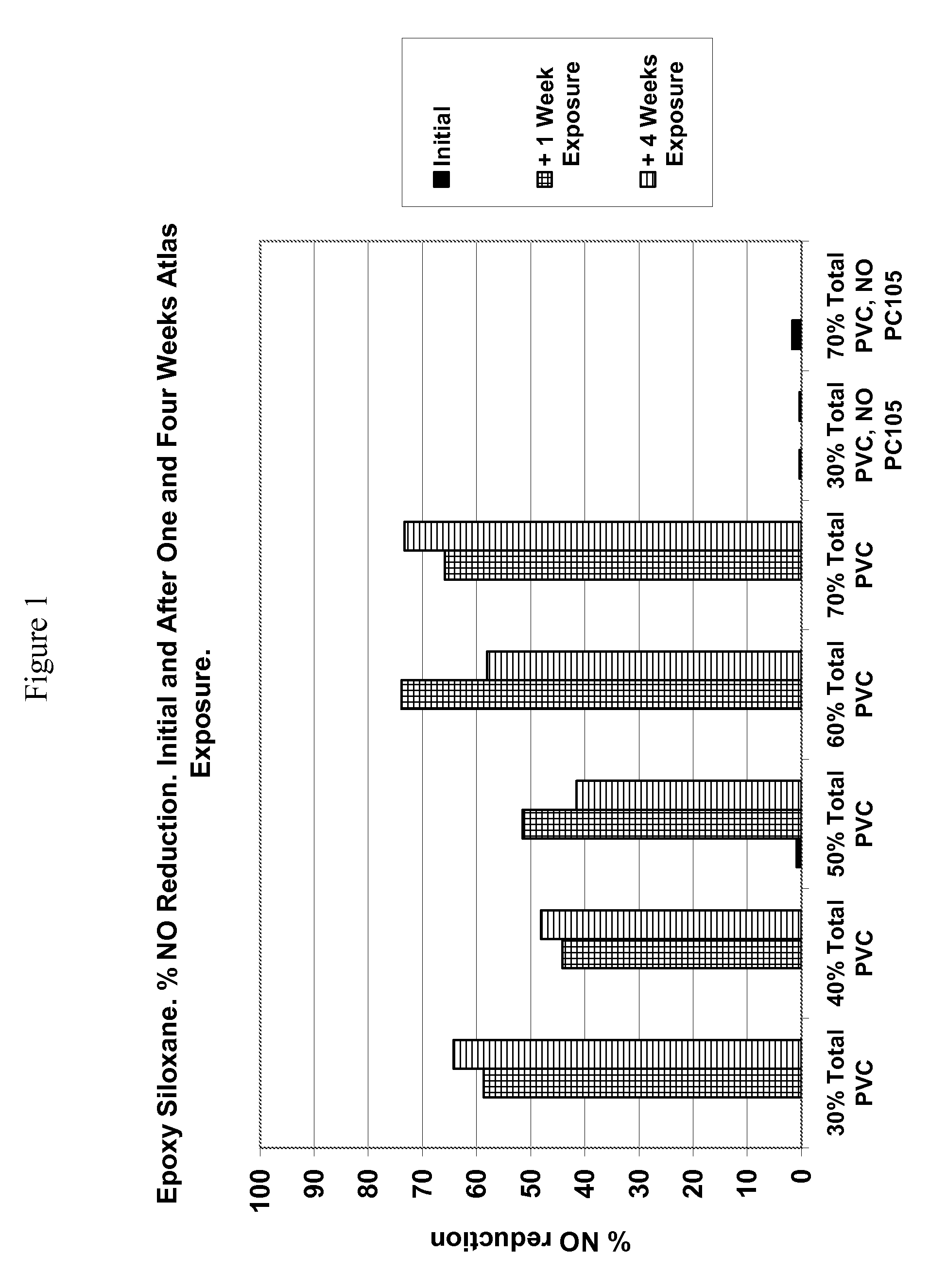

[0107]The complete methodology for determining NOx removal is described in U.S. Patent Pub. 2007 / 0167551, the disclosure of which is hereby incorporated by reference. Briefly, the samples were placed in an air-tight sample chamber and sealed. The sample chamber is in communication with a three channel gas mixer (Brooks Instruments, Holland) through which NO (nitric oxide), NO2 (nitrogen dioxide), and compressed air containing water vapor are introduced into the chamber at predetermined levels. Coatings comprising epoxy siloxane binder sold under the trade names SILIKOPON® EF and DYNASYLAN® AMEO were prepared from compositions comprising 7.5% PC105 photocatalytic TiO2 and 15% Tiona 595 pigmentary TiO2 (PVC) with total % PVC levels of 30%, 40%, 50%, 60%, and 70%. The difference in total PVC in the coatings was made up by the extender, calcium carbonate. The samples are irradiated with 8 W / m2 UV radiation in the range of 300 to 400 nm from a UV Lamp...

example 2

Optimization of NO Activity

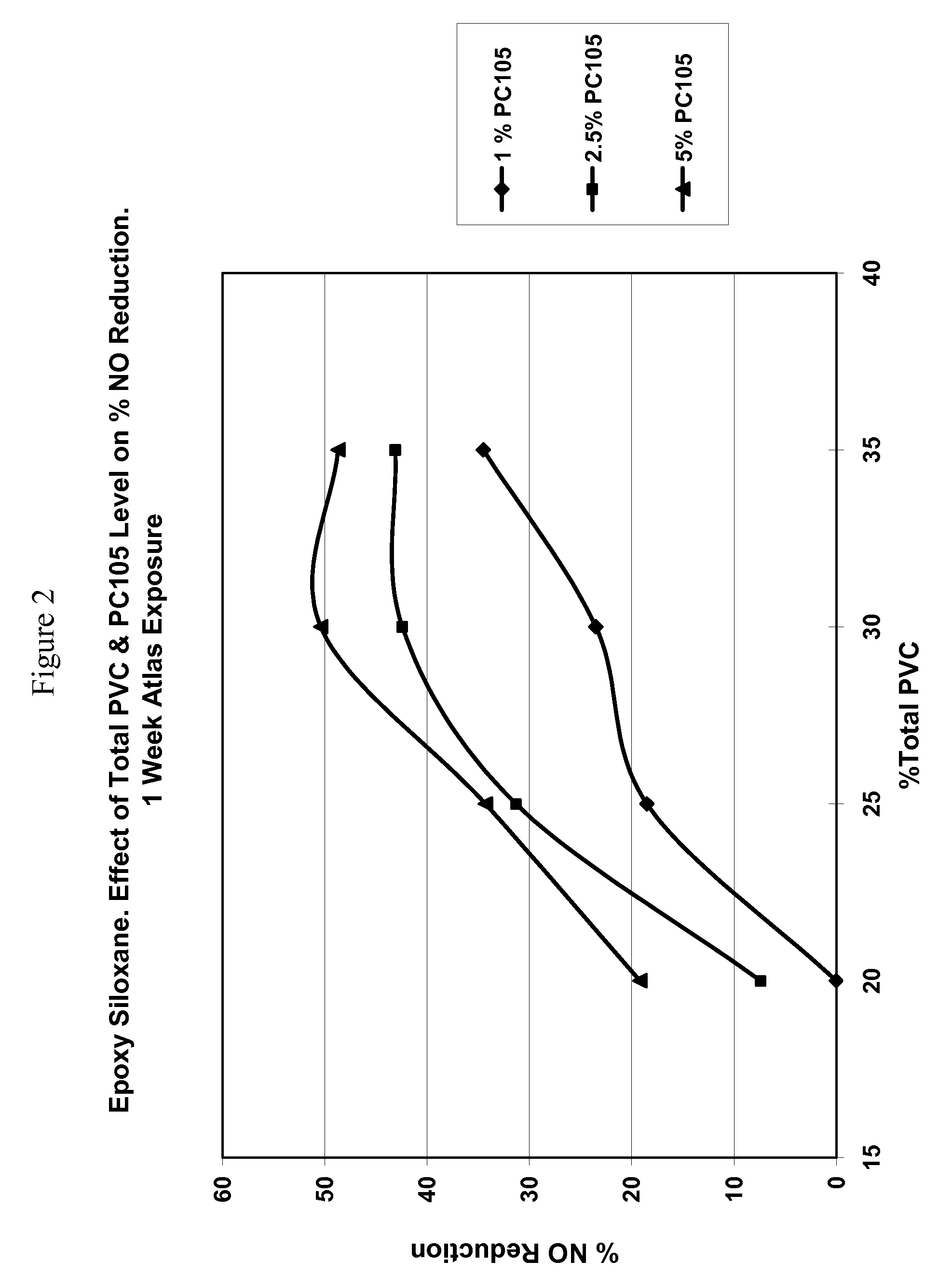

[0111]The photocatalytic activity and durability of coatings with lower levels of total PVC and catalytic TiO2 were evaluated. Coatings comprising epoxy siloxane binder with 15% PVC Tiona 595 pigmentary TiO2, photocatalytic PC105 TiO2 concentrations of 1%, 2.5% and 5% (PVC) and total PVC levels of 20%, 25%, 30% and 35% were evaluated for NO reduction activity initially and after 7 and 28 days exposure in the Atlas Weatherometer. The pigmentary TiO2 in the samples was kept constant at 15% PVC and the difference in PVC was made up by calcium carbonate. The percentage NO removed as measured with the Nitrogen Oxides Analyser Model ML9841B is shown for 0, 7 and 28 days weathering in Table 1 below. The percentage of NO reduction after 7 days weathering is depicted graphically in FIG. 2.

TABLE 1% Total PVC% PC105InitialAfter 7 daysAfter 28 days350.00.00.00.0200.00.90.40.0201.0000202.50.07.412.8205.00.019.221.5251.0−1.818.57.3252.53.431.326.7255.02.234.326.4301.0−0...

example 3

Coating Durability Correlated to Photocatalyst Level Durability

[0113]The durability of various photocatalytic coatings derived from compositions comprising photocatalytic TiO2 and an epoxy siloxane binder was evaluated. Coatings were applied to stainless steel panels and the durability evaluated as weight loss per 100 cm2 of coating and exposed to accelerated weathering conditions for various timeframes. The complete methodology for determining durability of the paints is described in U.S. Patent Pub. 2007 / 0167551, the disclosure of which is hereby incorporated by reference. The methodology involves accelerated weathering of 20 to 50 micron thick paint films on a stainless steel substrate in a Ci65A Weatherometer (Atlas Electric Devices, Chicago) under a 6.5 kW Xenon source. The level of UV radiation at the panel surface being 0.50 W / m2 UV at 340 nm. The radiant heat from the Xenon light source raising the temperature of the white panels to 35° C. and water spray was applied for 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com