Microbial fuel cell with improved anode

a fuel cell and microorganism technology, applied in the field of microorganism fuel cells, can solve the problems of low degree of efficiency in electrical power output, inability to operate efficiently, and inability to improve the efficiency so as to reduce the electrical resistance of microbial fuel cells, improve the efficiency of operation, and improve the effect of electrical power outpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General Procedure

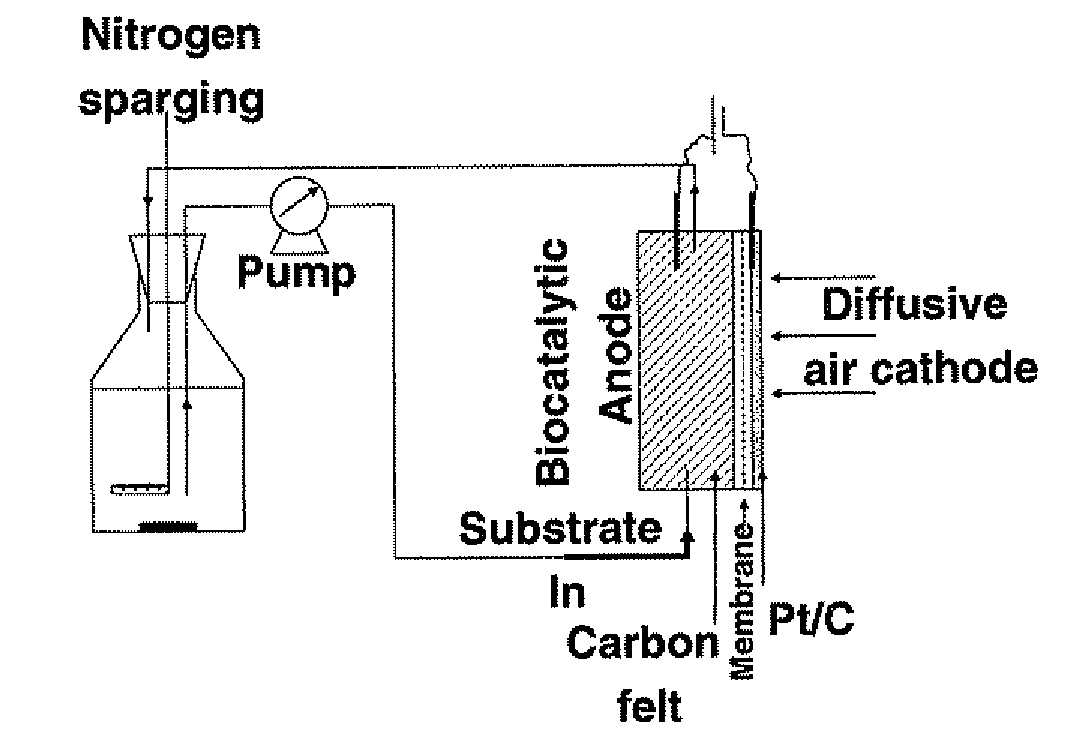

[0080]The enrichment strategy selected for the development of a biofilm-forming exoelectrogenic biocatalyst was a combination of improved anode design and specific operating modes. The features of the design included: a compact anode with negligible electrode spacing, a high anode electrode surface to volume ratio and a flow-through design with forced flow to enable removal of planktonic cells (FIG. 1). The features of the operating modes were as follows: mode I: growth with electrode as the sole electron acceptor, mode II: carbon starvation mode and, mode III: step-wise reduction of external load.

[0081]A compact anode filled with carbon felt with minimal dead volume (i.e., a volume ratio of nearly 1) provided a high surface area for exoelectrogen growth. A flow-through design allowed easy removal of non-biofilm forming organisms via periodic replenishment of the anodic fluid. A forced flow-through anode enabled removal of mediators and organisms attached to the bio...

example 2

Microbial Fuel Cell Construction

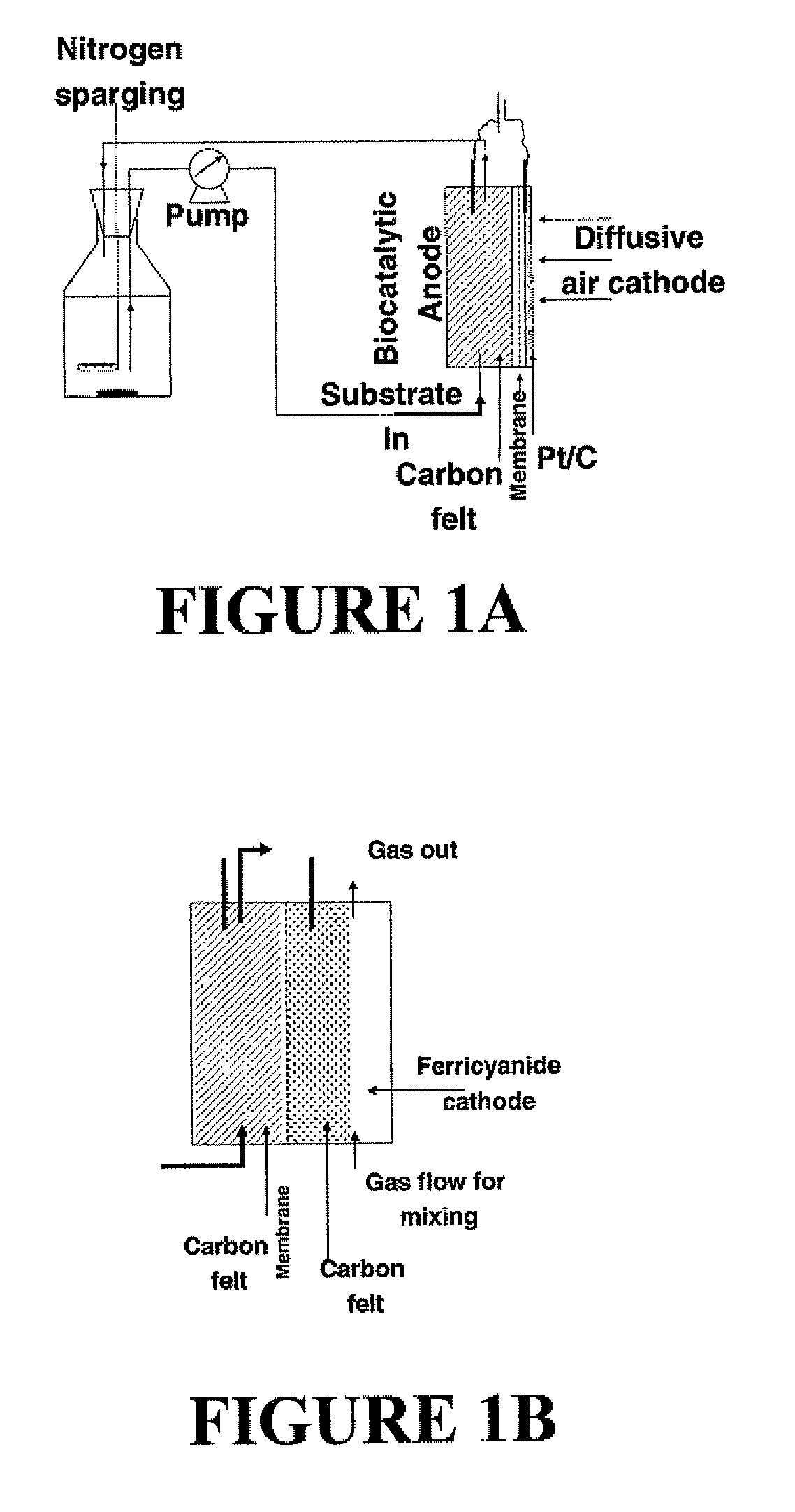

[0087]The MFC used in this study consisted of an anode chamber (4 cm diameter×1.27 cm thickness) containing carbon felt as the electrode material and a platinum-coated carbon as the cathode (Pt / C air-cathode) separated by a Nafion-115 membrane (FIG. 1A). The MFC chamber was made up of a 4 cm diameter PVC pipe, enclosed within two Lexan end plates, bolted together with metal bolts. The liquid flow through the anode was directed upwards through the carbon felt. A gold wire was used as a current collector for the air-cathode and a graphite rod was used for the anode. The Pt / C air-cathode was used during biocatalyst enrichment, while a ferricyanide-cathode (FIGS. 1B, C) was used for determining the maximum power density. The electrode for the ferricyanide cathode was also made using a pipe (4 cm diameter×2.54 cm thick) with carbon felt as the electrode material (2.54 cm×2.54 cm×0.625 cm). The felt was suspended by a carbon rod in a way that the felt surfa...

example 3

Establishment of a Biofilm on the Anode

[0088]The nutrient medium (Medium AC-1) used for enrichment consisted of 975 mL of a sterile mineral solution and 12.5 mL, each of filter sterilized Wolfe's mineral solution and vitamin solution (Gorby, Y. A., et al., PNAS, 103, 11358-11363 (2006)). The mineral solution was made up of 0.31 g NH4Cl, 0.13 g KCl, 4.97 g NaH2PO4.H20 and 2.75 g Na2HPO4.H20 per liter of nanopure water (see, for example, Liu, H. et al., Environ. Sci. Technol., 38, 4040-4046 (2004)), which was adjusted to a pH of 7.0 with 1N NaOH prior to sterilization. The nutrient medium AC-1 (200 ml) was placed in a glass bottle reservoir. (anode liquid reservoir) and recirculated through the anode chamber at 4-7 mL / min (FIG. 1A). The medium was deaerated with nitrogen to remove the dissolved oxygen.

[0089]The anode chamber of the MFCs was inoculated with a 1 mL sample of anaerobic digester slurry collected from a Knoxville municipal wastewater treatment plant. The inoculum was added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com