Method for drying copper sulfide concentrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

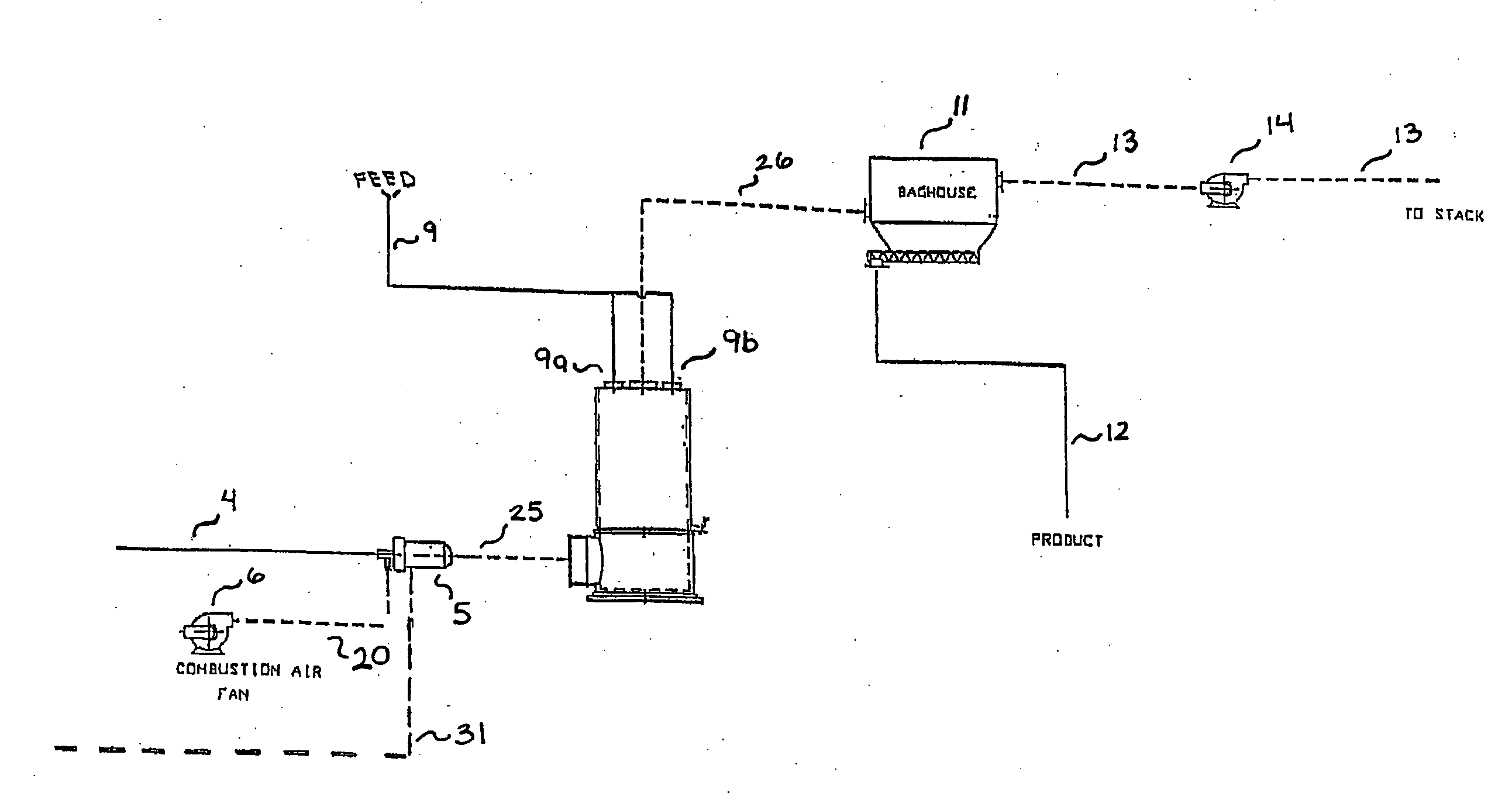

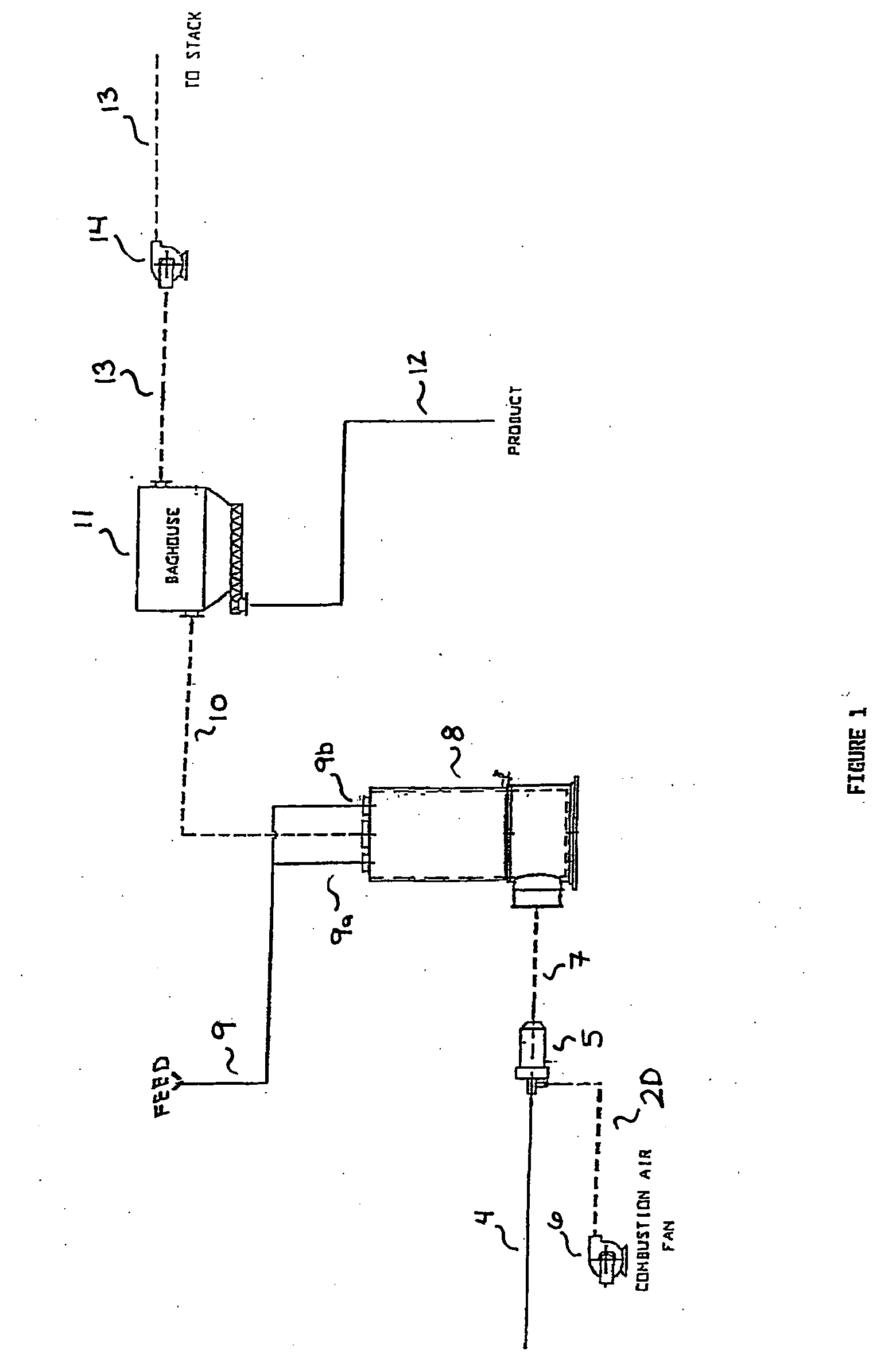

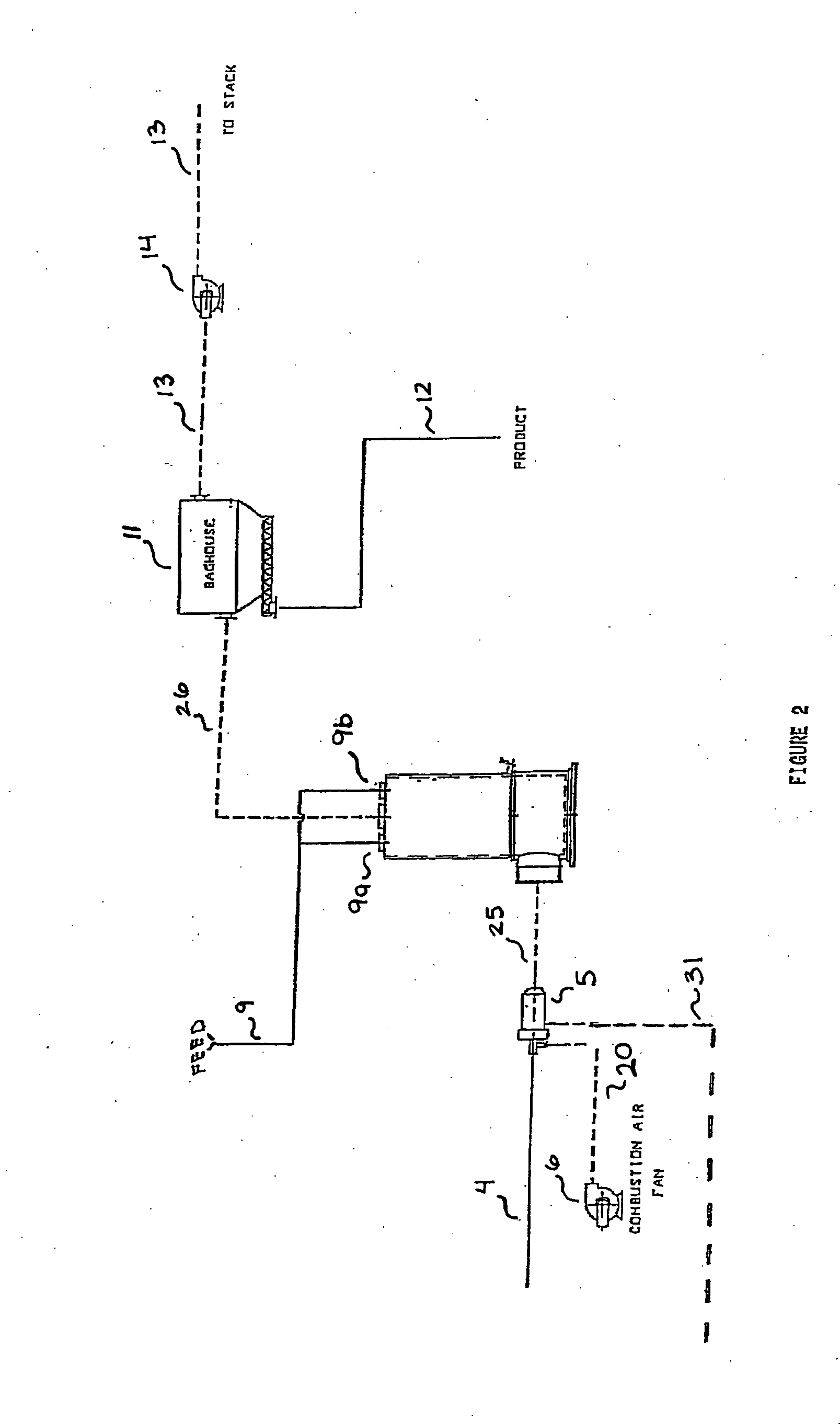

[0016]It should be understood at the outset that identical reference numbers on the various drawing sheets refer to identical elements of the invention. It should also be understood that the following description is intended to completely describe the invention and to explain the best mode of practicing the invention known to the inventors but is not intended to be limiting in interpretation of the scope of the claims. The drawings are not necessarily to scale, emphasis instead being placed upon illustrating principles of the invention.

[0017]Any conventional process can prepare the copper concentrates used in the practice of this invention, most preferably a flotation process, and such concentrates typically contain between about 10 and 50 percent by weight copper. The concentrates contain other metals, e.g. iron, lead, bismuth, arsenic, molybdenum, one or more precious metals. etc., that are associated with the copper in the ore deposit, and these metals, as well as the copper, are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com