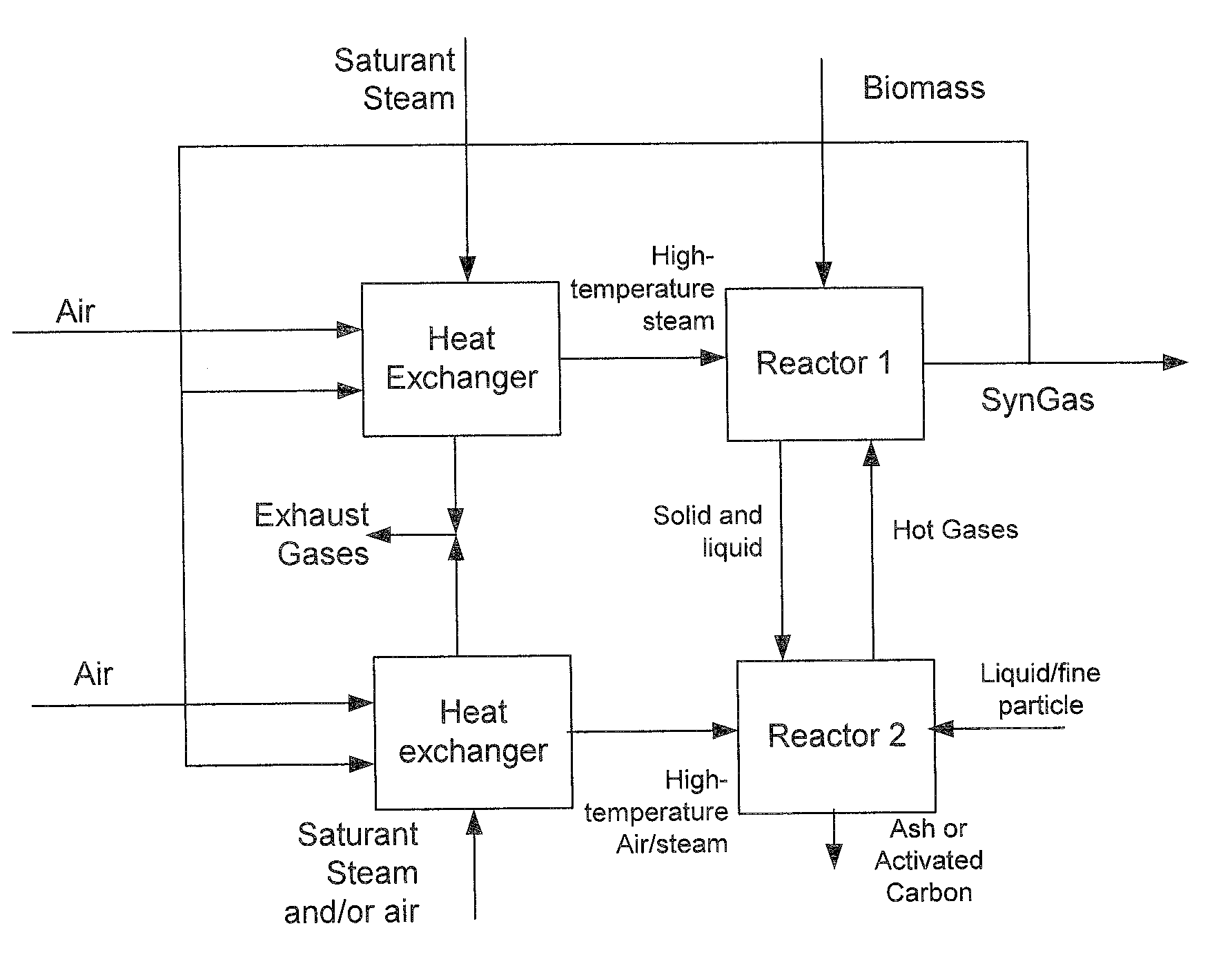

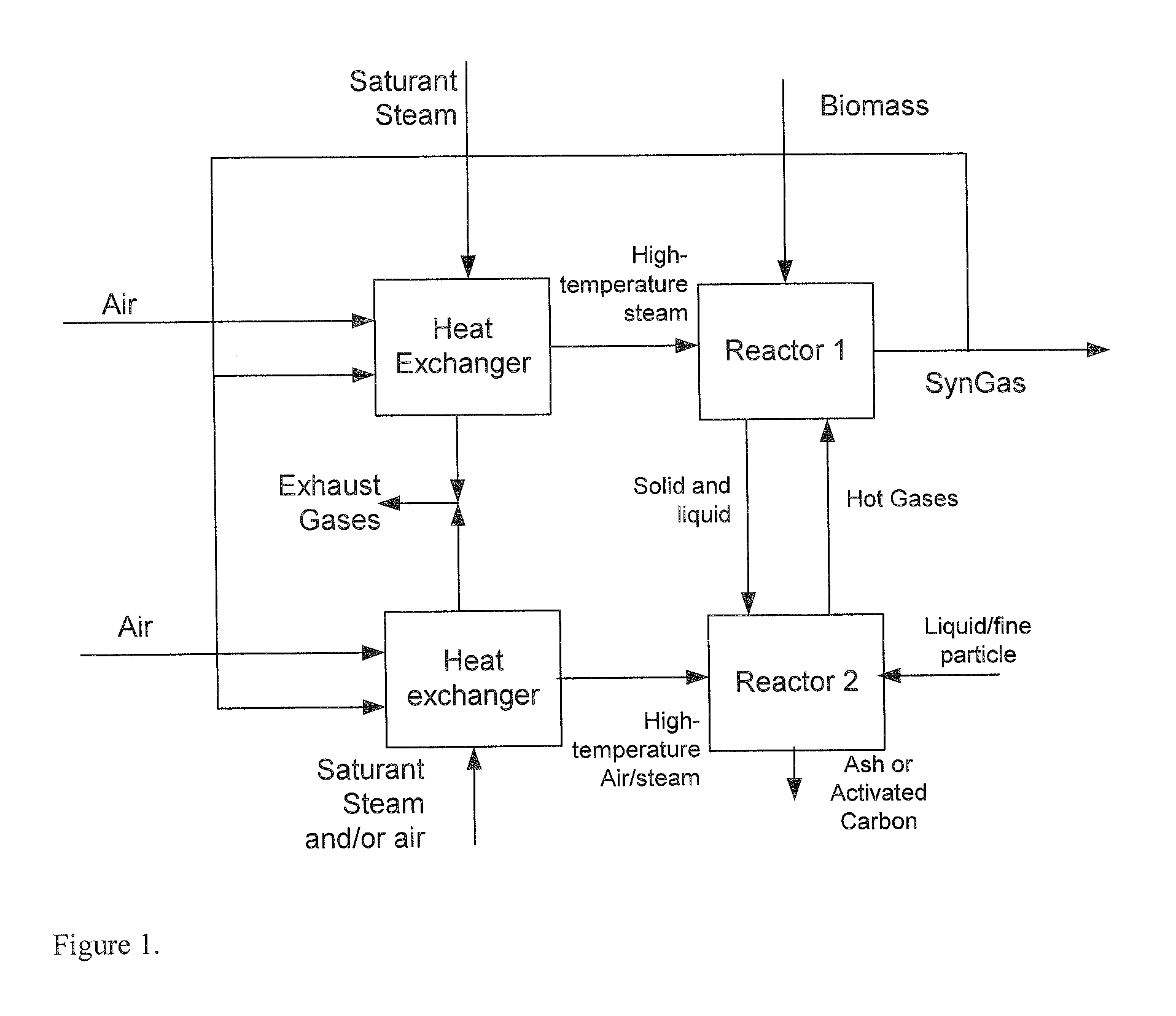

Two-stage high-temperature preheated steam gasifier

a gasifier and high-temperature technology, applied in the direction of gasification process details, special form destructive distillation, inorganic chemistry, etc., can solve the problems of low caloric value, small partial pressure, and unfavorable other valuable gasification reactions, so as to minimize the need for separation of by-products and keep the undesired dilution of gaseous products to a minimum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

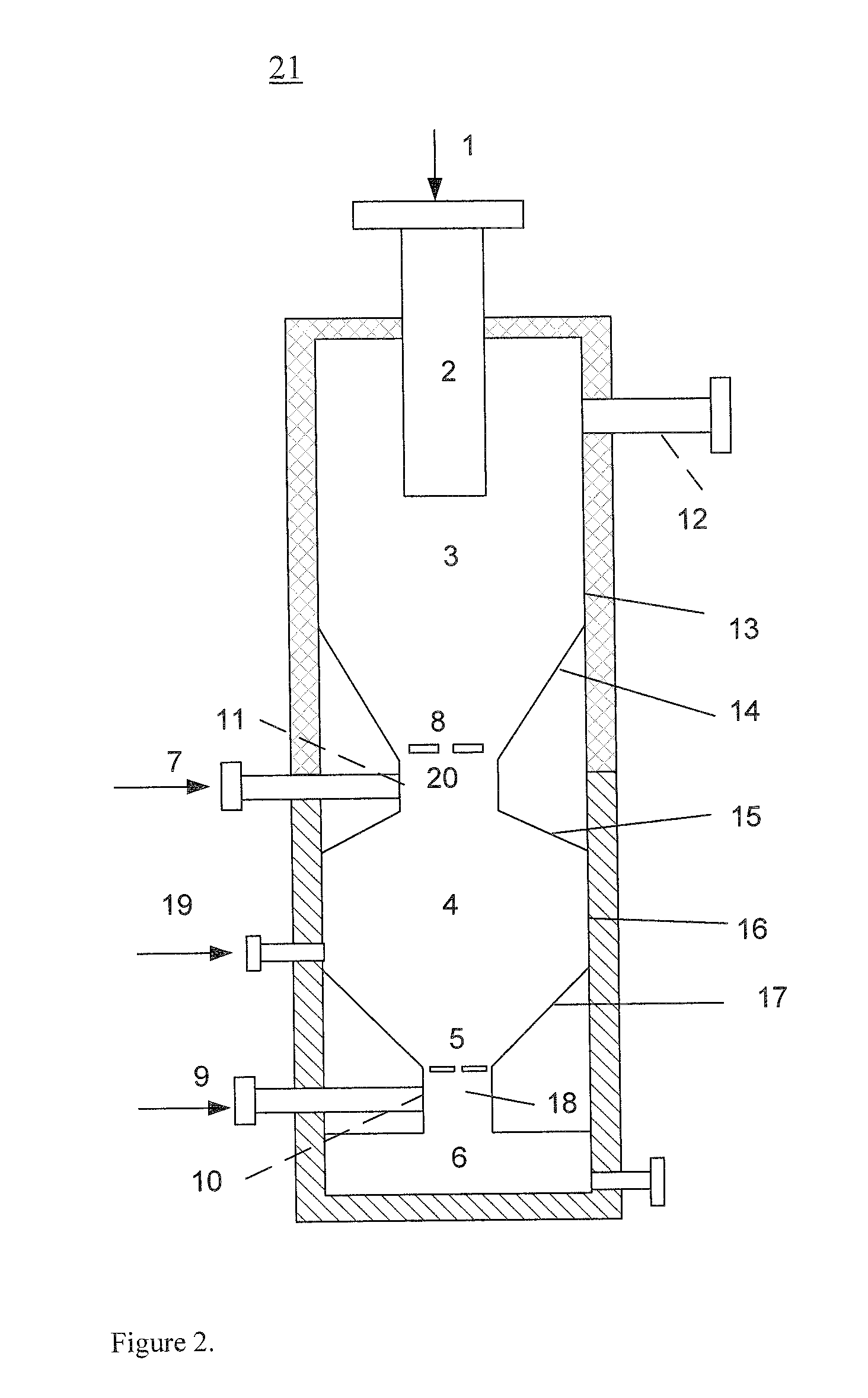

[0074]97 kg / h of wood pellets 1 with a diameter around 8 mm is feed into the first reactor from the inlet 2 by weight at room temperature (15° C.). The properties of the wood pellets are shown in Table 1.

TABLE 1Proximate and ultimate analysis of the feedstocks usedProximate analysisWood Pellets (WP)Total Moisture (SS187170)8%Ash content (SS-187171)0.5-0.6% (dry)LHV (SS-ISO562)17.76 MJ / kg (as received)Volatile matter (SS-ISO)84% (dry)Density630-650 kg / m3Ultimate analysis (dry compositions)Wood PelletsSulphur (SS-187177)S0.01-0.02%Carbon (Leco-600)C50%Hydrogen (Leco-600)H6.0-6.2%Nitrogen (Leco-600)NOxygen (Calculated)O43-44%Ash fusion temperatures (oxidizing conditions)Wood PelletsInitial deformation, IT1350-1400° C.Softening, ST1450-1500° C.Hemispherical, HT 1500° C.Fluid temperature, FT1500-1550° C.

example 2

[0075]A 60 kg / h of Refuse Derived Fuel (RDF), a pellet formed fuel made from paper fiber mixed with other substances such as fabric fiber, wood chips and plastics, was used as feedstock, with a diameter of about 8 mm, and was feed into the first reactor 3 from the top 1 by weight, i.e. by the action of gravity, at room temperature (15° C.). The properties of the RDF pellets are shown in Table 2.

TABLE 2Proximate and ultimate analysis of the RDF feedstock usedProximate analysisRefused Derived Fuel (RDF)Total Moisture (SS187170)2.9%Ash content (SS-187171)6.0% (dry)LHV (SS-ISO562)26.704 MJ / kg (as received)Volatile matter (SS-ISO)84.4% (dry) Density472 kg / m3Ultimate analysis (dry compositions)RDFSulphur (SS-187177)S19 0.09%Carbon (Leco-600)C63.3%Hydrogen (Leco-600)H 8.9%Nitrogen (Leco-600)N 0.3%Oxygen (Calculated)O20.95% Ash fusion temperatures (oxidizing conditions)RDFInitial deformation, IT1210° C.Softening, ST1220° C.Hemispherical, HT1230° C.Fluid temperature, FT1240° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com