Powder material, electrode structure using the powder material, and energy storage device having the electrode structure

a technology of electrode structure and powder material, which is applied in the direction of basic electric elements, electrochemical generators, cell components, etc., can solve the problems of high resistance of batteries, difficult to increase capacity, and serious problems, and achieve high power density, high energy density, and rapid charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0208]The present invention will be described in further detail referring to examples.

[0209][Preparation of Active Material for Negative Electrode of Energy Storage Device]

[0210]Examples of procedure of preparing powder material

Reference Example m1

[0211]Mixing silicon powder obtained by micronizing metal silicon powder of 96.0% or more purity with medium mill using zirconia beads in isopropyl alcohol to average particle diameter of 0.2 μm, tin powder, copper powder, boron powder, graphite powder of 195:90:15:3:30 in proportion by weight; inserting the mixture into an attritor; implementing 24-hour mechanical alloying treatment at rotation of 300 rpm in argon gas atmosphere; and Si—Sn—Cu—C alloy powder was obtained.

example m1

[0212]Mixing silicon powder obtained by micronizing metal silicon powder of 96.0% or more purity with medium mill using zirconia beads in isopropyl alcohol to average particle diameter of 0.2 μm, tin powder, copper powder, boron powder, graphite powder of 195:90:15:3:30 in proportion by weight; inserting the mixture into an attritor; implementing 24-hour mechanical alloying treatment at rotation of 300 rpm in argon gas atmosphere; and Si—Sn—Cu—B—C (also abbreviated as SiSnCuC) alloy powder with an average diameter of 0.2 μm was obtained. Next, 80 parts by weight of the obtained Si—Sn—Cu—C alloy powder and 20 parts by weight of lithium titanate Li4Ti5O12 powder with specific surface area being 33.5 m2 were mixed and were ground for 6 hours with a planetary ball mill using zirconia balls to obtain Si—Sn—Cu—B—C alloy-Li4Ti5O12 composite material powder with an average diameter of 1 μm or less.

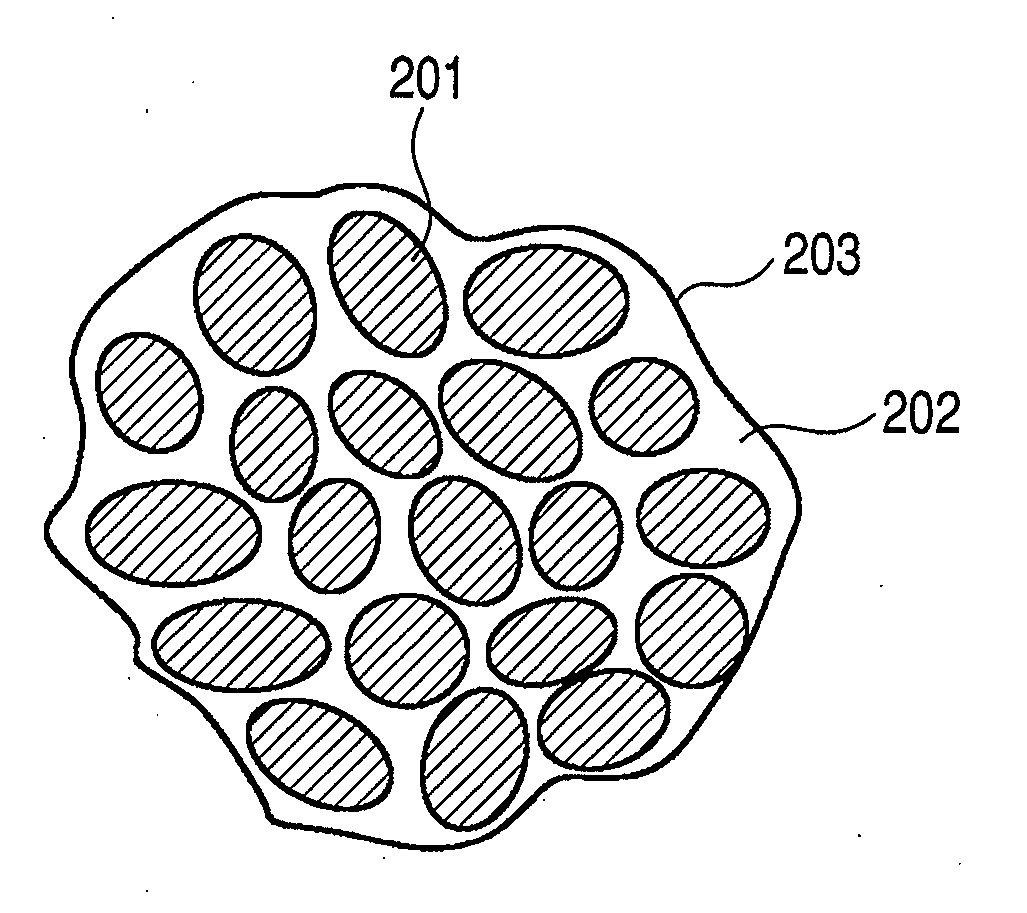

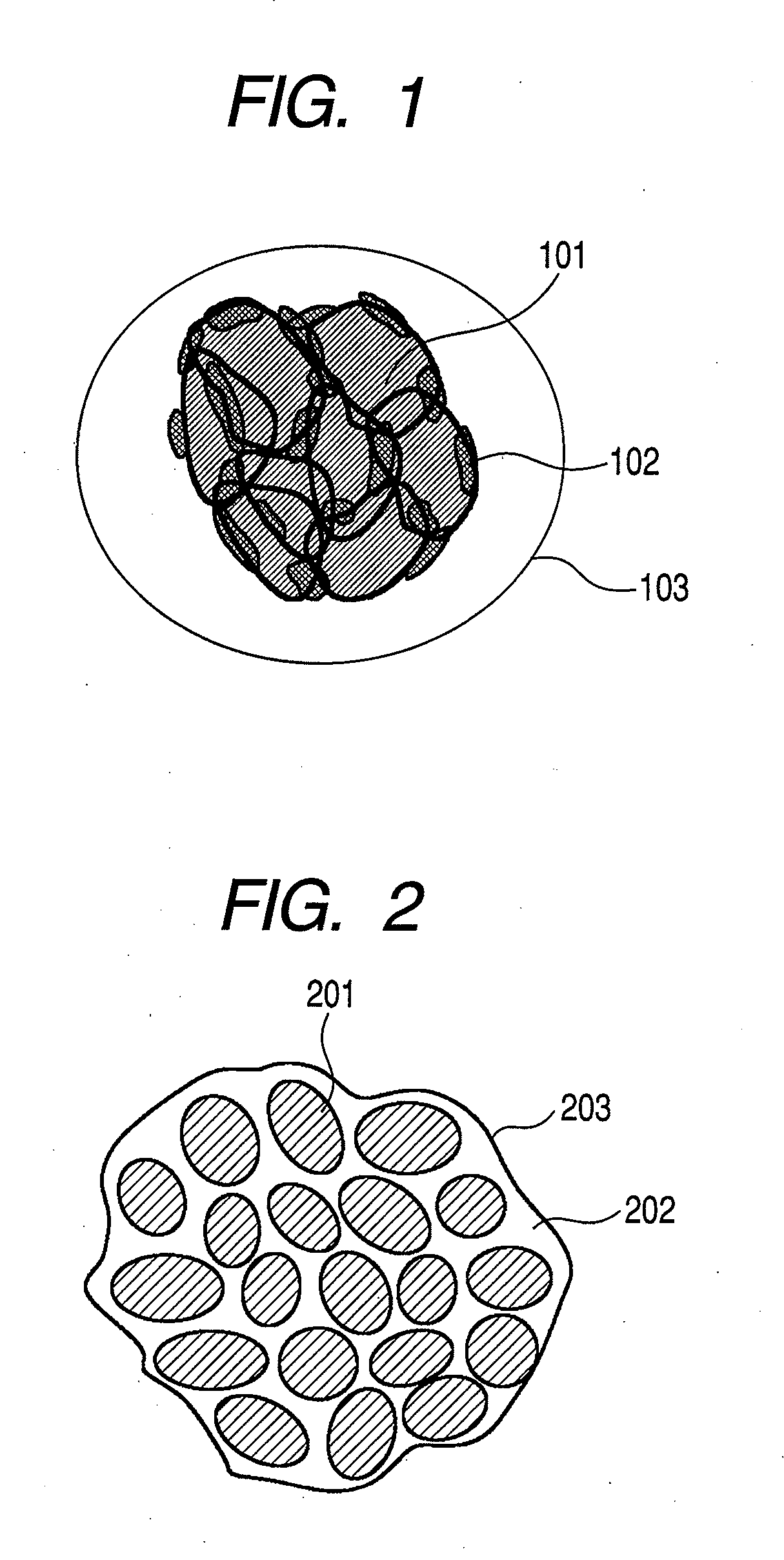

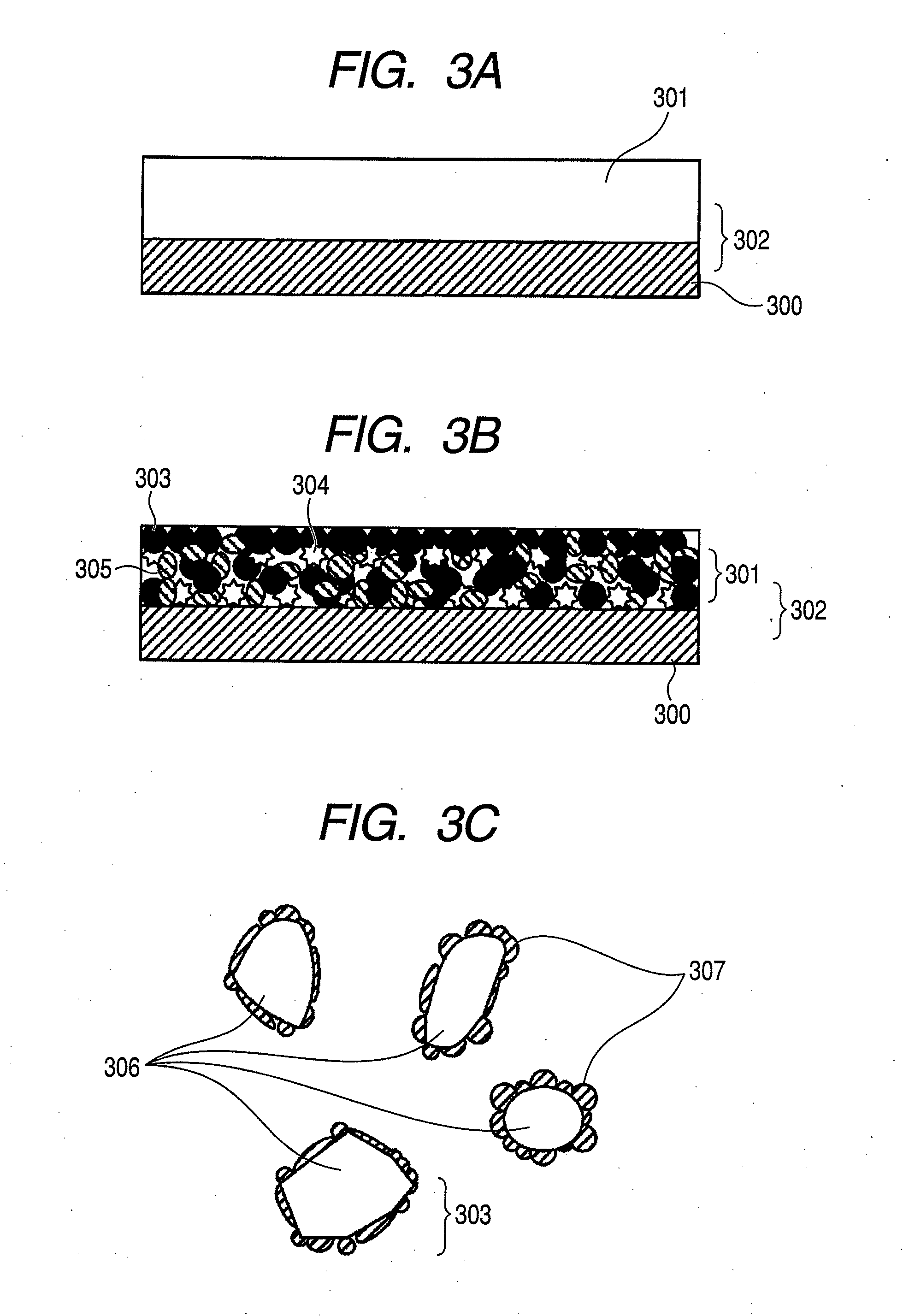

[0213]The above described obtained composite powder was irradiated with ultrasonic wave in eth...

example m2

[0218]Mixing Li4Ti5O12 powder in the amount of 20 parts by weight into silicon powder in the amount of 80 parts by weight with purity of 99% or more and with average particle diameter of 4 μm, grinding the mixture with a planetary ball mill using zirconia balls at 300 rpm for six hours, an electrode material of Si—Li4Ti5O12 composite powder with the average particle diameter of 2 ρm or less was obtained.

[0219]Likewise Example M1, the sample, for observation with a transmission electron microscope, of Si—Li4Ti5O12 for composite powder was produced. With that observation sample, mode observation and composition analysis were carried out. The analysis result thereof is illustrated in FIG. 12.

[0220]Here, the mapping image of Si, Ti and O elements are in the diagrams respectively indicated as SiKα1, TiKα1, OKα1. Based on the mapping images and secondary electronic images of those elements, Ti element distribution and O element distribution nearly overlap and a region of Si element distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com