Crosslinkable acrylate adhesive polymer composition

- Summary

- Abstract

- Description

- Claims

- Application Information

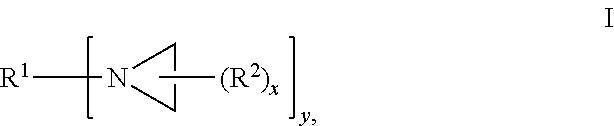

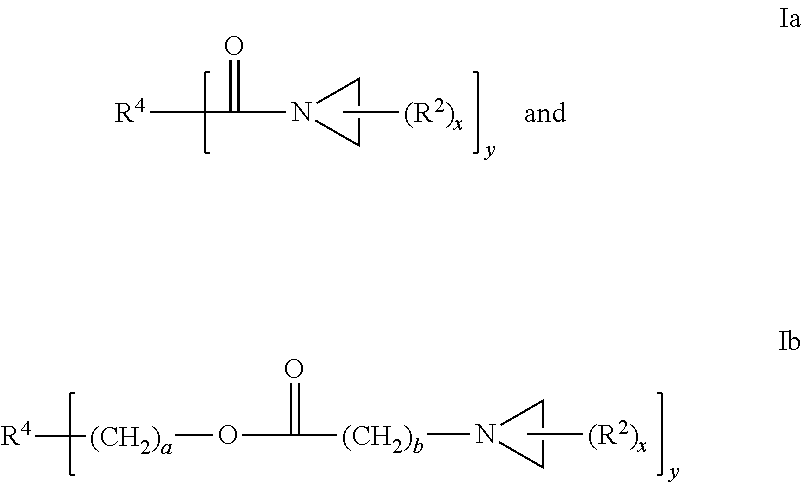

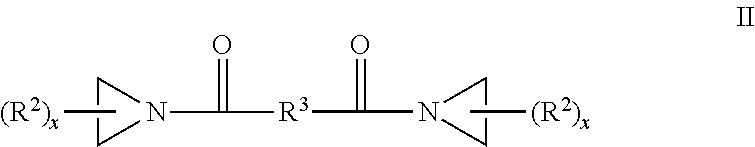

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Test Methods

Peel Adhesion Test [ASTM D 3330 / D 3330M-04]

[0079]Two 0.5 inch by at least 4 inch (˜1.3×10 cm) strips of adhesive coated onto Mitsubishi Hostphan™ primed polyester film were adhered to a glass plate by rolling a 2 kg roller onto the tape. At least 3.5 lineal inches (˜8.9 cm) of the adhesive coated film sample was in contact with the glass plate and a short portion of the sample (the“free end”) was kept from contacting the glass plate. The free end of the sample was pulled back to form a nearly 180° angle with the portion of the sample that was adhered to the glass plate. The free end of the sample was attached to the clamp of the adhesion tester scale. The peel adhesion test was initiated as soon as the sample was adhered to the glass plate, that is, the “dwell time” was kept as close to zero as possible. The force required to peel the tape was measured in ounces per 0.5 inches width with a platen speed of 90 inches per minute. The measurements for the two tape samples we...

examples 1-10

Effect of Acid Content on Pot Life of Bisamide

[0082]Syrup polymer compositions were prepared using IOA and AA using the procedures of U.S. Re 24906 (Ulrich) using 100 parts of IOA and the indicated amounts of AA of Table 1.

[0083]Bisamide / IOA solution (20 wt %) was added to these syrups at 0.22 parts level based on 100 parts of IOA. The mixtures were well mixed on a roller. Viscosity of these mixtures was monitored with a Brookfield Engineering Viscometer (Model: LVDVII+, Brookfield Eng. Labs. Inc. Stoughton, Mass. 02072) at room temperature. The spindle 4 was used and the spin speed was 30 RPM.

[0084]Results are summarized in the Table 1. It is believed that when AA is at 0.08 parts and Bisamide is at 0.22 parts, only half of aziridine group is reacted. When AA is at 0.15 parts and Bisamide is at 0.22 parts, all of aziridine groups and all acid groups are reacted. As can be seen, when acid AA content in the syrup is lower than 1.66 parts based on 90 parts of IOA, 0.22 parts of Bisami...

examples 11-18

Effect of Acid Content on Pot Life of Bisamide when Post-Add AA to the Syrup

[0085]In the following Examples, low AA content syrup polymers were prepared using the procedures of U.S. Re 24906 (Ulrich) with 100 parts of IOA and the indicated amounts of AA of Table 2. These solute polymers were combined with additional AA monomer so the total AA is 11.1 parts per 100 parts of IOA as shown in Table 2. Bisamide / IOA solution (20 wt %) was added to these syrups at 0.22 parts level based on 100 parts of IOA. Viscosity of these mixtures was monitored as previously described. Results are summarized in Table 2.

[0086]As can be seen, when the initial AA content in the syrup was lower than 2.78 parts (relative to 100 parts of IOA) the Bisamide has adequate pot life. When the AA is higher than 5.56 parts, the syrup gelled.

TABLE 2AA postViscosity (c.P)IOAAAaddedafter indicated time (hours)Ex.(parts)(parts)(parts)824144111000.0811.0328202840284012″0.1510.9637803840384013″0.5510.5632403240324014″1.11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com