Heat management in ethylene oligomerization

a technology of ethylene oligomerization and heat management, which is applied in the direction of hydrocarbon preparation catalysts, bulk chemical production, organic chemistry, etc., can solve the problem of polymer as a by-product, and achieve the effect of reducing the formation of unwanted polymers and not being energy efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

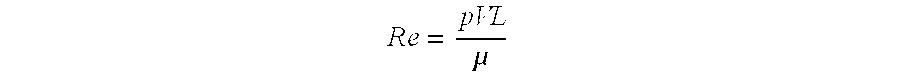

Method used

Image

Examples

examples

[0117]The following abbreviations are used in the examples:[0118]Å=Angstrom units[0119]NMR=nuclear magnetic resonance[0120]Et=ethyl[0121]Bu=butyl[0122]iPr=isopropyl[0123]c*=comparative[0124]rpm=revolutions per minute[0125]GC=gas chromatography[0126]Rx=reaction[0127]Wt=weight[0128]C4's=butenes[0129]C6's=hexenes[0130]C8's=octenes[0131]PE=polyethylene

Part I: Preferred Ligand Synthesis

General

[0132]This section illustrates the synthesis of a preferred but non-limiting ligand for use in the present invention.

[0133]All reactions involving air and or moisture sensitive compounds were conducted under nitrogen using standard Schlenk or cannula techniques, or in a glovebox. Reaction solvents were purified prior to use (e.g. by distillation) and stored over activated 4 Å sieves. Diethylamine, triethylamine and isopropylamine were purchased from Aldrich and dried over 4 Å molecular sieves prior to use. 1-Bromo-2-fluoro-benzene, phosphorus trichloride (PCl3), hydrogen chloride gas and n-butyllith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com