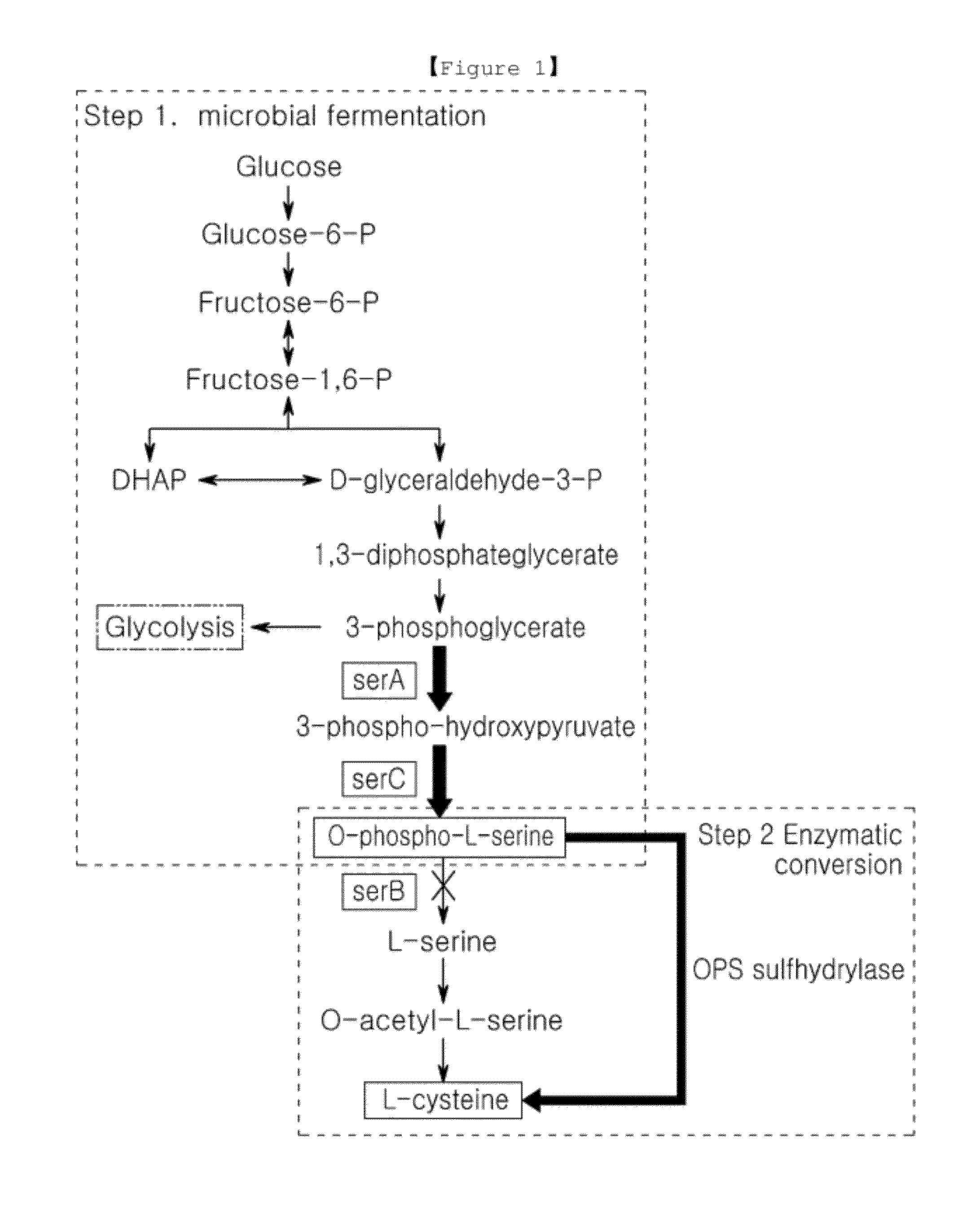

Microorganism producing o-phosphoserine and method of producing l-cysteine or derivatives thereof from o-phosphoserine using the same

a technology of o-phosphoserine and microorganisms, which is applied in the direction of microorganisms, enzymology, transferases, etc., can solve the problems of difficult industrial application of the conversion process, strong user aversion, and environmental pollution, and achieves high yield and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Phosphoserine Phosphatase (serB) Deficient Corynebacterium Strain

[0048]Corynebacterium glutamicum 13032 was modified by deleting the serB gene (SEQ ID NO: 7, EC 3.1.3.3) encoding phosphoserine phosphatase, which catalyses the synthesis of L-serine from O-phosphoserine, therefrom. To this end, a fragment for inactivation of serB was constructed. In this regard, primers were designed for the preparation of the recombinant strain 13032-ΔserB of the present invention. First, the serB sequence of Corynebacterium glutamicum 13032 was obtained with reference to the data of the NIH GenBank, and primers SEQ ID NOS: 9 to 14 were synthesized on the basis of the serB sequence. For the site-specific gene disruption, a pDC vector which cannot replicate in Corynebacterium glutamicum was employed. A pDC-ΔserB plasmid in which the open reading frame of serB was internally disrupted was constructed and adopted for the preparation of a site-specific serB gene deletion in Corynebacterium...

example 2

Assay for O-Phosphoserine Productivity in the Phosphoserine Phosphatase Deficient Corynebacterium Strain

[0050]The mutant strain CB01-0047, resulting from the deletion of serB from Corynebacterium glutamicum 13032, which was anticipated to accumulate O-phosphoserine, was spread over BHIS plates and incubated overnight in a 30° C. incubator.

[0051]Afterwards, the colonies appearing on the BHIS plates were inoculated in 25 mL of a titer medium shown in Table 1 using a platinum loop and then incubated at 30° C. for 48 hours with shaking at 200 rpm. The results are summarized in Table 2, below.

TABLE 1CompositionAmount (per liter)Glucose100gKH2PO41.1g(NH4)2SO445gMgSO4•7H2O1.2gHSM20gTrace elements20mlCalcium carbonate30gpH7.2Trace elementsBiotin0.09gThiamine0.45gCa-Panthenate0.45gNCA3gFeSO4•7H2O9gMnSO4•4H2O9gZnSO4•7H2O0.045gCuSO4•5H2O0.045g

TABLE 2SugarO-phosphoserineStrainOD 562 nmconsumed (g / L)(g / L)C. glutamicum251000.0213032CB01-00476.5230.07

[0052]The CB01-0047 strain was observed to grow...

example 3

Preparation of E. coli Strain Having the Reduced Activity of Phosphoserine Phosphatase (SerB)

[0053]E. coli was modified by deleting the serB gene (SEQ ID NO: 8) encoding phosphoserine phosphatase, which catalyses the synthesis of L-serine from O-phosphoserine, therefrom. The deletion mutant E. coli K12 was prepared using the one-step inactivation method (Datsenko K A and Wanner B L, Proc. Natl. Acad. Sci., 97: 6640-6645, 2000) to delete an antibiotic-resistant maker gene. To prepare the serB deletion strain, first, PCR was performed on a pKD3 plasmid (Datsenko K A and Wanner B L, Proc. Natl. Acad. Sci., 97: 6640-6645, 2000; GenBank No. AY048742) using a pair of primers of SEQ ID NOS: 15 and 16. The PCR product was (introduced into competent cells of pKD46 containing E. coli K12 (Datsenko K A and Wanner B L, Proc. Natl. Acad. Sci., 97: 6640-6645, 2000; GenBank No. AY048746) by electroporation. Thereafter, strains that showed resistance to chloramphenicol were subjected to PCR to conf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com