Depositing Calcium Fluoride Template Layers for Solar Cells

a solar cell and template layer technology, applied in the direction of instruments, other domestic articles, transportation and packaging, etc., can solve the problems of limiting the potential for silicon pv cost reduction, high recombination rate than low angle grain boundaries, and high cost of silicon wafer fabrication and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

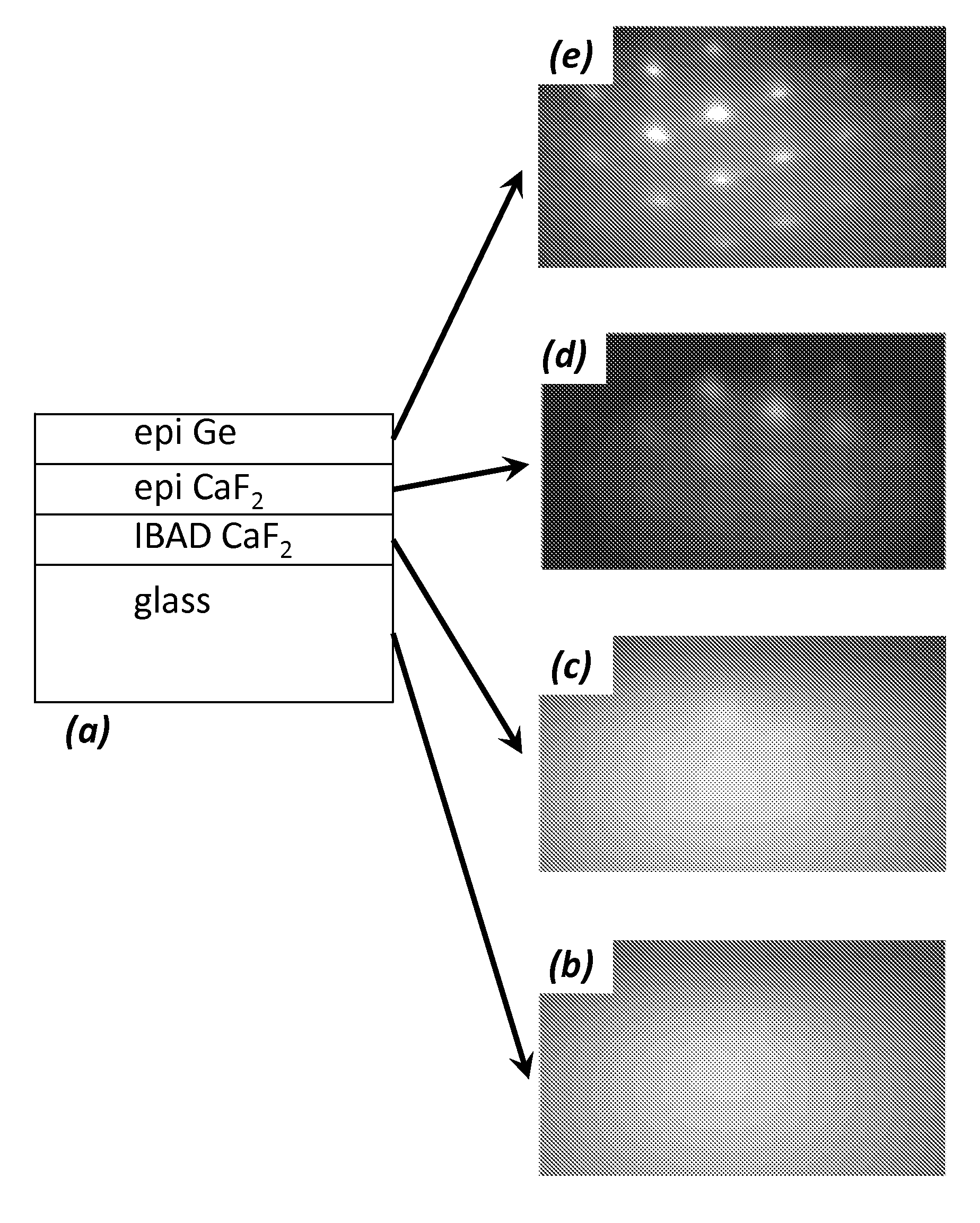

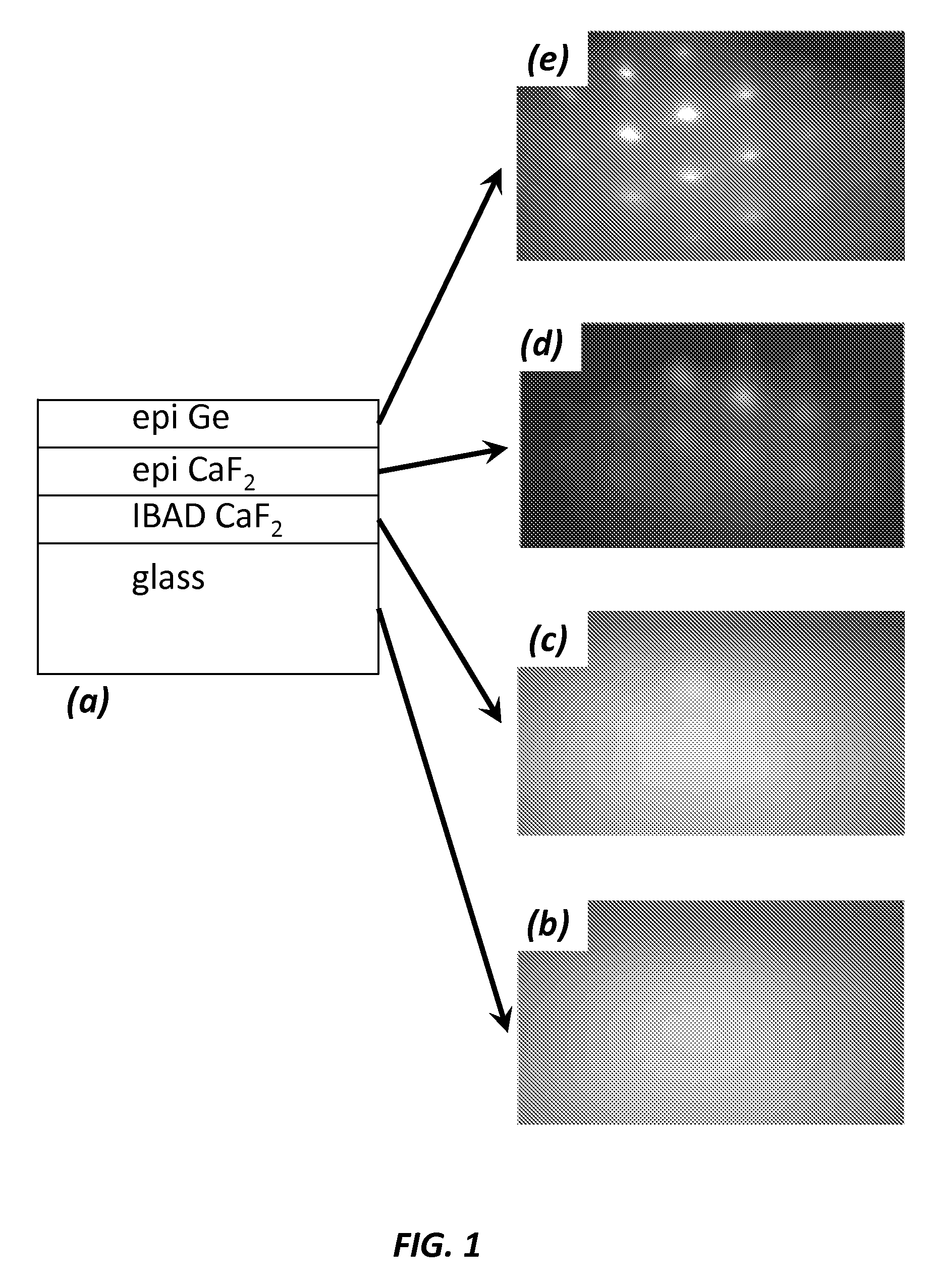

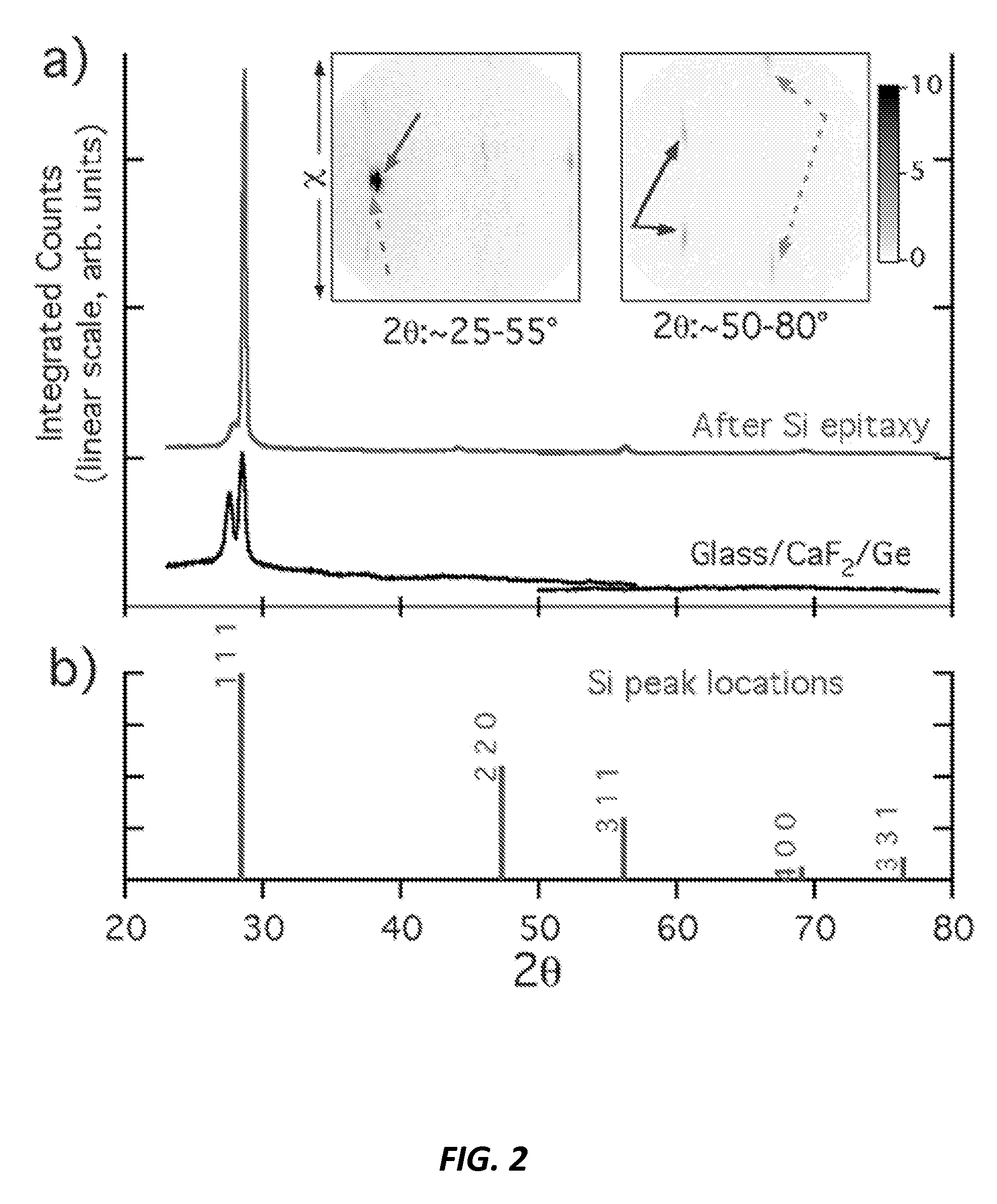

[0030]Ion beam assisted deposition is a proven technology for growing thin films with biaxial texture, similar to single crystals. In one embodiment, the invention provides a PV device and a method to control the grain boundary alignment in a polycrystalline thin film of silicon. This is achieved by depositing a biaxially aligned layer of calcium fluoride (CaF2) or yttrium oxide-stabilized zirconium oxide (YSZ) that can be used as a template layer for the subsequent deposition of epitaxial layers. The biaxial alignment of the template layer is achieved by using the ion beam assisted deposition process (IBAD). The IBAD template layer can then be used as a platform for subsequent deposition of heteroepitaxial silicon or other materials. This invention enables the deposition of polycrystalline silicon on technical substrates of large areas or long lengths. The invention may be used to deposit polycrystalline silicon on large areas for photovoltaic applications. The technology can be ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| grain widths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com