Asymmetric membranes for use in nanofiltration

a technology of asymmetric membranes and nanofiltration, applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of not being widely applied to the separation of organic solvent solutes, no reports to date describing the application of osn in strongly basic or acidic organic solvent environments, and integrally skinned polyimide membranes formed by phase inversion are not stable in all solvents, so as to achieve low or no flux and high flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

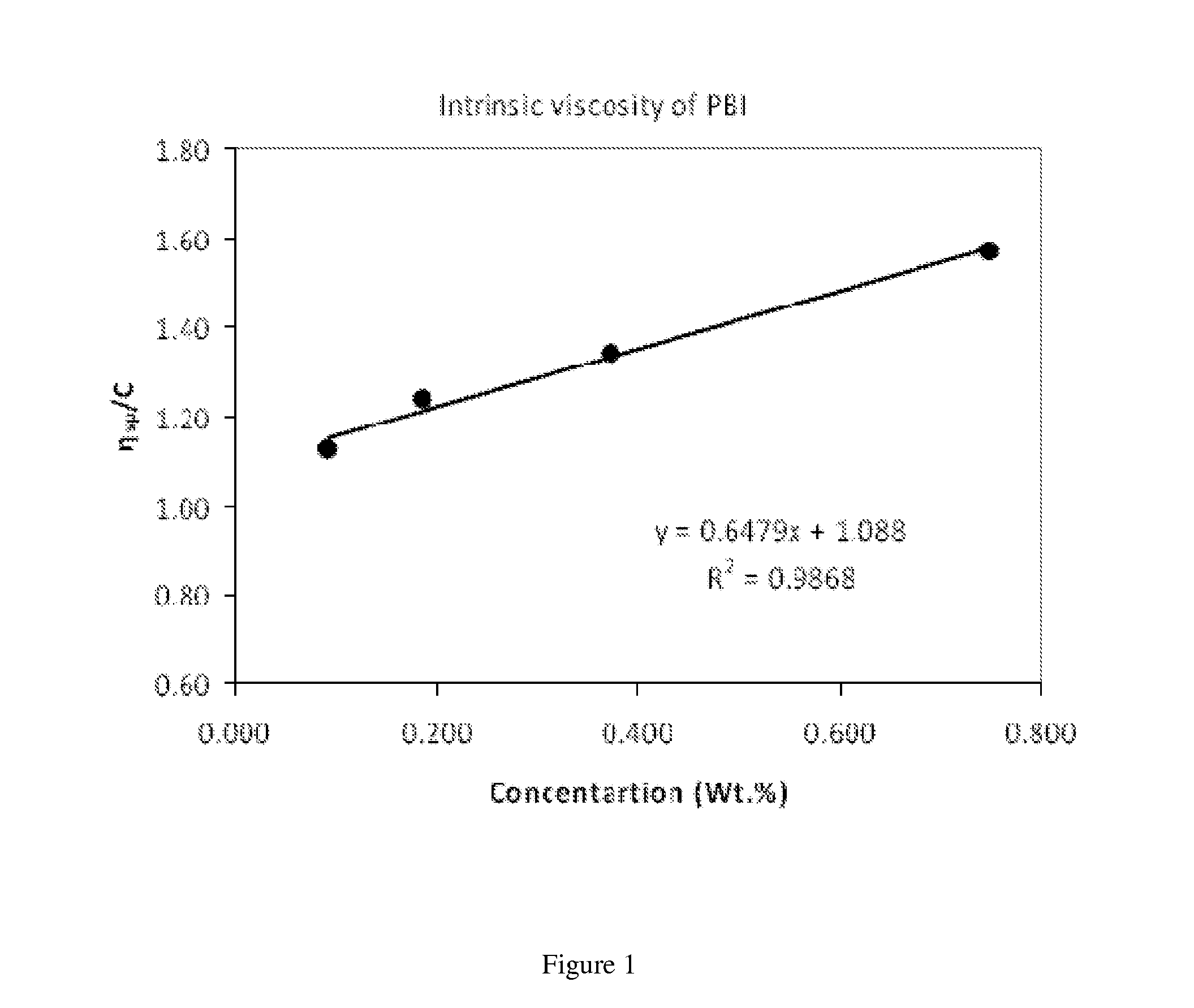

[0082]Polybenzimidazole polymer was synthesised as follows.

[0083]625 gm of Polyphosporic acid (PPA) was weighted in a 1 liter 3 neck round bottom flask at room temperature followed by the fixing of flask to the overhead stirring assembly equipped with oil bath. The oil was heated to 155° C., at around 125° C. the addition of tetra-amine was started under the constant flow of dry nitrogen. The addition was very slow in such a way that it lasted for more than 15 minutes. After the completion of tetraamine addition the temperature was further raised to 170° C. and kept constant for 45 minutes flowed by diacid addition. The reaction was further kept stiffing for next 4 hrs at 170° C. After 4 hrs the reaction temperature was further raised to 210° C. for next 2.5 hrs followed by 230° C. for 2 hrs. At the end of reaction the viscous polymer solution was poured in large excess of water in the form of fine continuous fiber.

[0084]The crude PBI fibers were crushed in to fine pieces and furthe...

example 2

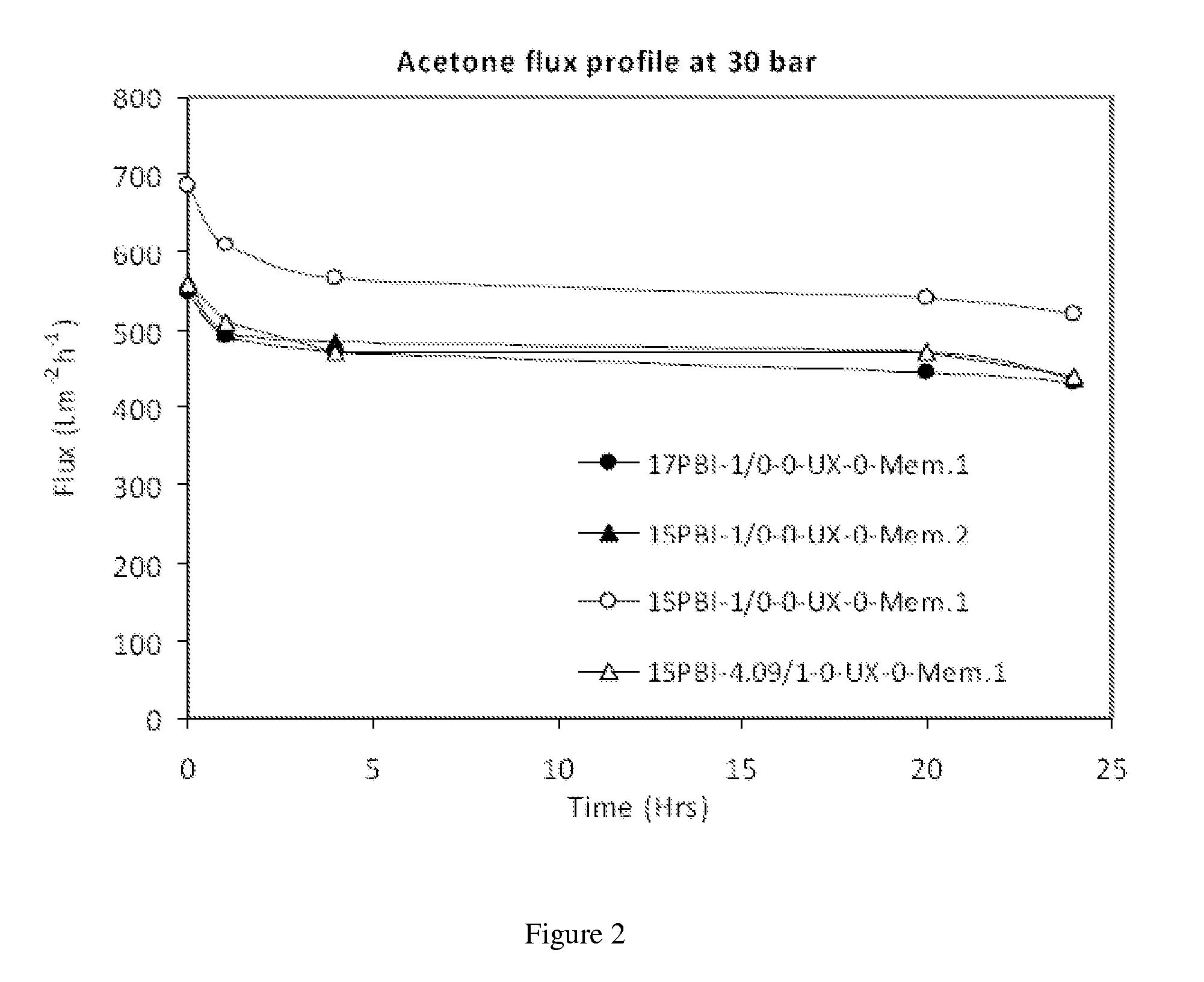

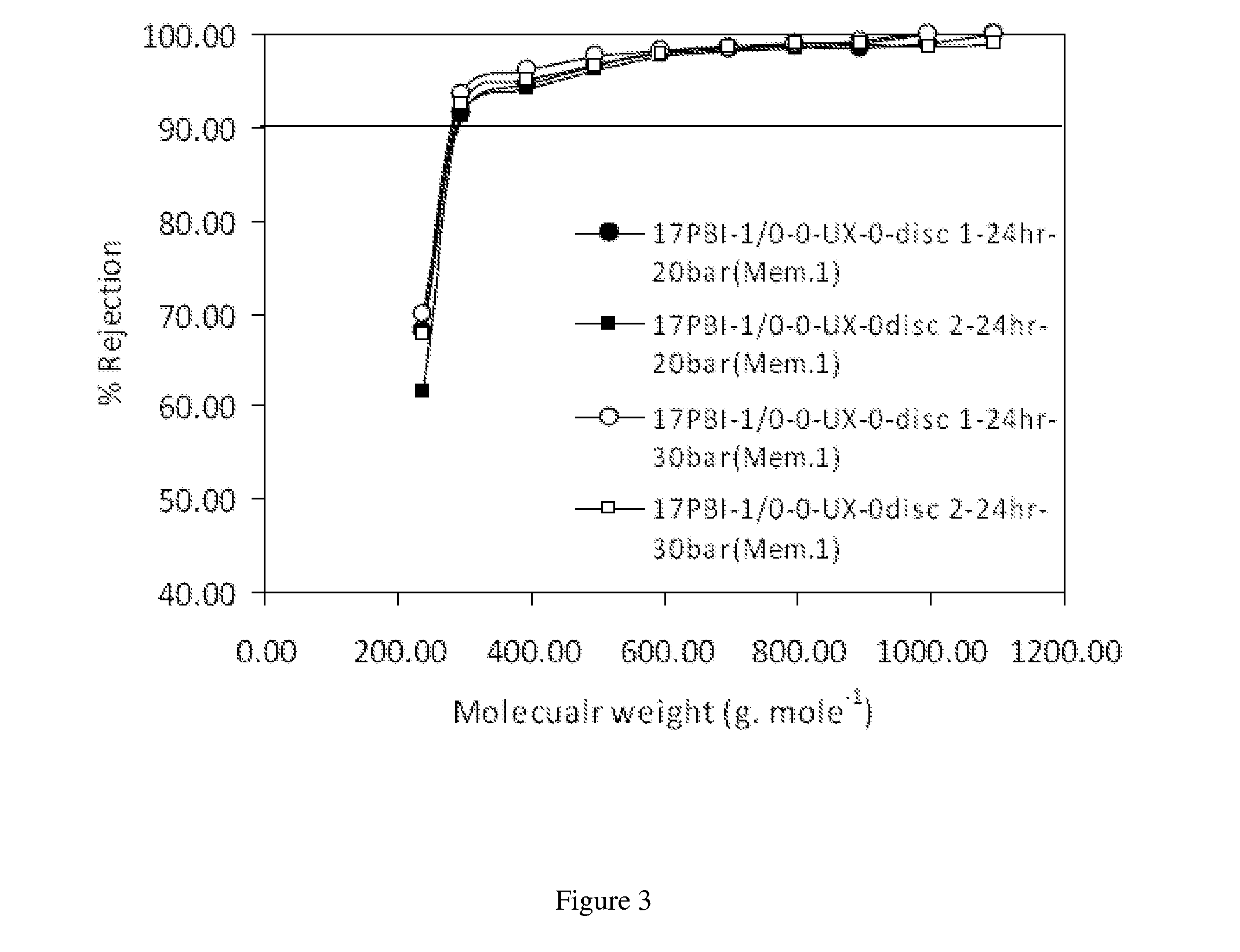

[0092]Membranes were formed as in Example 1 above and then crosslinked as follows.

[0093]The membranes were immersed into a bath of methyl isobutyl ketone and crosslinker (dibromobutane) for 12 hrs. at 60° C. temperature. The membrane was then removed from the crosslinking bath and washed with IPA to remove any residual crosslinker. Following this, the membrane was immersed into a bath of IPA / polyethylene glycol 400 (40 / 60, v / v %) to prevent drying out. The membranes were then air dried to remove excess solvent. The dried membrane was fixed to the glass plate with the help of PVC tape and heated in oven at 100° C. for 1 hr.

[0094]These crosslinked membranes were then tested for flux and rejection as described above. The data from these tests is shown in FIGS. 9 and 10.

example 3

[0095]Crosslinked polybenzimidazole membranes were prepared as per Example 3 and were immersed into undiluted solutions of monoethanolamine and trifluoroacetic acid and held at 30° C. The membranes were monitored for stability over 4 weeks. No change in the membranes appearance or properties was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com