Process for the manufacture of butanol or acetone

a technology of acetone and butanol, which is applied in the field of process for the manufacture of butanol or acetone, can solve the problems of inability to commercialize on a large scale, many prove unsuitable, and the cost of biobutanol production is currently higher, so as to reduce the concentration of cu, reduce the conversion rate of sugar to abe, and reduce the effect of cu concentration below inhibitory levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

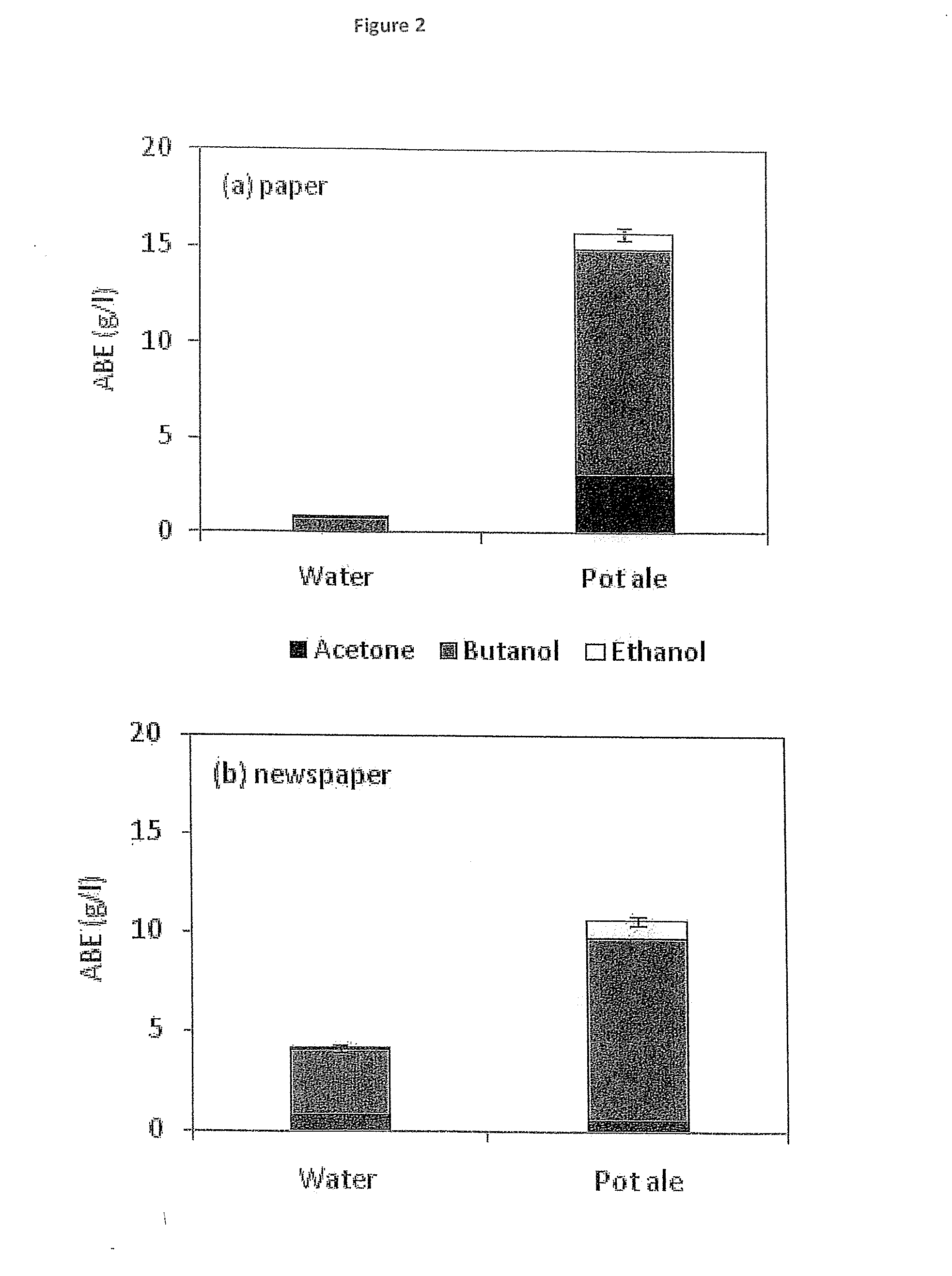

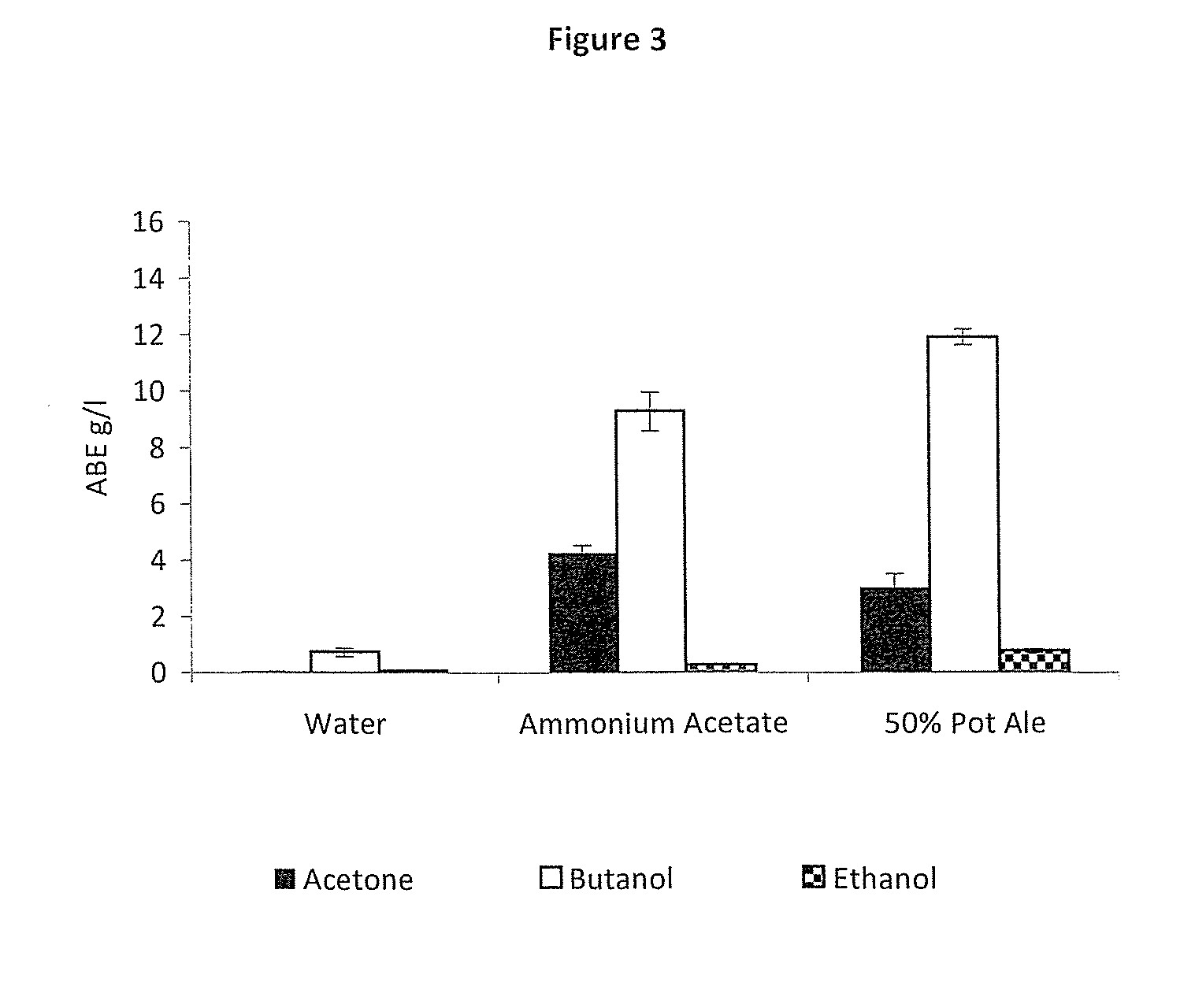

[0072]Reference Example 1 and Example 2 and 3 show the effect of pH and free copper ion concentration of the substrate upon the fermentation process. In both of Reference Example 1 and Example 3, glucose was used as the carbohydrate source. Reference Example 1 is designated as a reference test because no pot ale was present in the substrate.

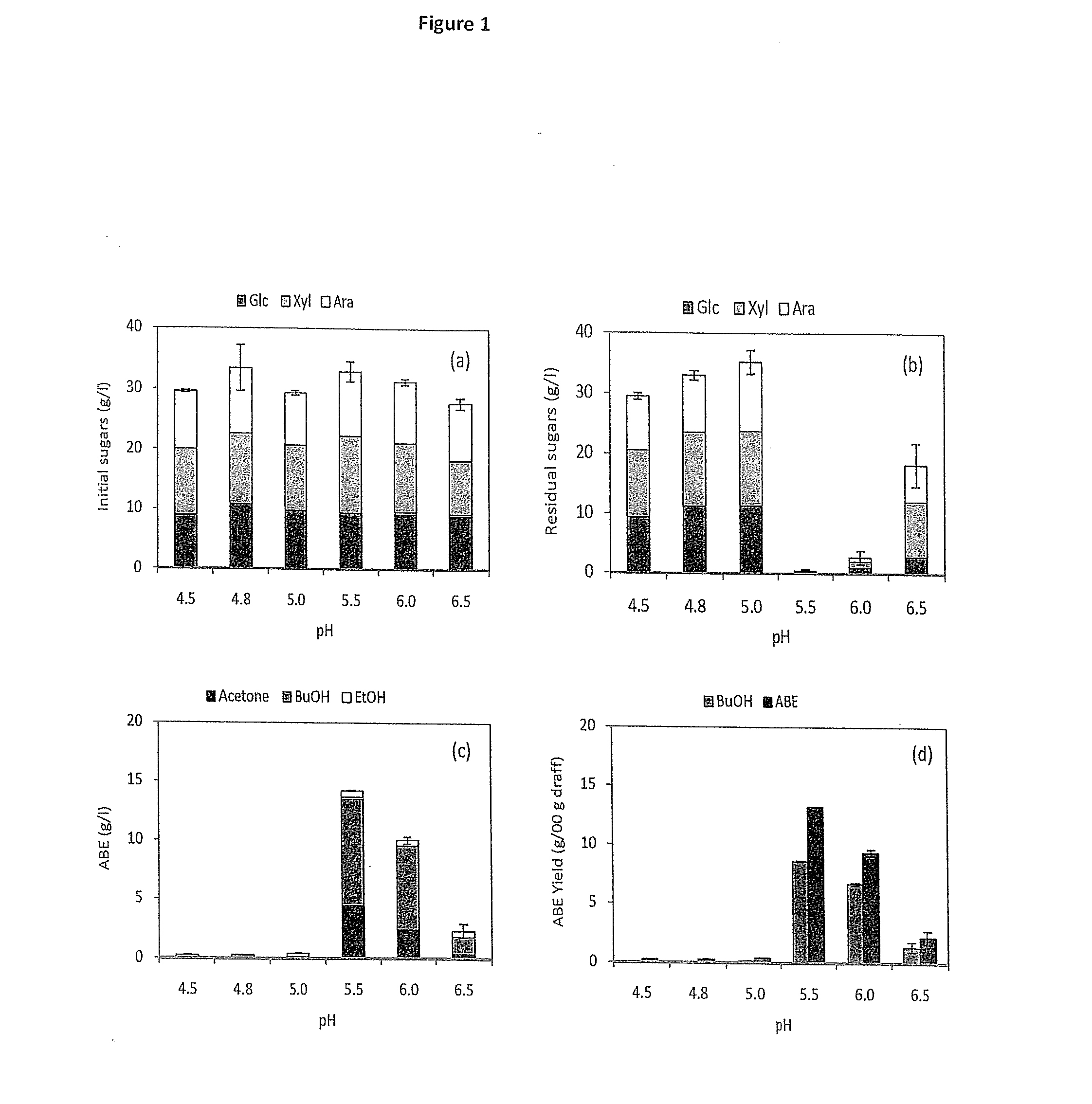

[0073]Reference Example 1 shows that ABE can be produced from the fermentation of glucose in a pH range of above 4.5 to 6.5. At a pH of 4.5 no glucose was consumed or ABE produced. At a pH of 6.5, only acids were produced, with no ABE. Example 2 shows a preferred initial range pH of about 5.5 for the fermentation of a substrate comprising pot ale and a substrate (draff).

[0074]Example 3 shows that undiluted pot ale has a concentration of free copper ions which is detrimental to fermentation, resulting in a reduction in ABE yield compared to a substrate without added free copper ions. Furthermore as the concentration of free copper ions was reduced...

reference example 1

Effect of pH Control on ABE Production by Clostridia

[0087]The effect of pH on fermentation of glucose in TYA media by C. acetobutylicum ATCC 824 was investigated. Fermentations were conducted at 1 L scale and the pH was controlled at a range of set points between pH 4.5-6.5 with automated addition of either alkali or acid. At pH 4.5, no glucose utilisation, acid or ABE production was detected. For all other fermentations, glucose was completely consumed within 48 hours and acids (butyric and acetic) and solvent (acetone, butanol and ethanol) were produced (Table 2). ABE production was highest at pH 4.8 and 5.0, corresponding to yields of 0.34 and 0.30 g ABE / g sugar, respectively. Acid production increased between pH 5.5 to 6.5, with a corresponding decrease in conversion of sugar to ABE. At pH 6.5, acids only were produced with final concentrations of 7.8 and 12.8 g / l acetic and butyric acid, respectively.

TABLE 1Conversion of 5% glucose to acid and ABE by C. acetobutylicumATCC 824 i...

example 2

Influence of Initial pH on ABE Production by Clostridia

[0088]The effect of initial pH on fermentation of a pre-treated substrate comprising draff and pot ale was investigated. Dried, milled draff was pre-treated by adding 10.5% (w / v) to 250 ml duran bottles with 0.08 M H2SO4 in 50% pot ale and sterilised at 121° C. for 15 min. After cooling, the pH was adjusted to between pH 5.0-6.0 by addition of 10 M NaOH and incubated with cellulase and hemicellulase enzymes at 33° C. for 24 hours. For fermentation, the initial pH of the solutions was adjusted to either 4.5, 4.8, 5.0, 5.5, 6.0 or 6.5 prior to inoculation with C. acetobutylicum ATCC 824. The initial sugar concentration was monitored before fermentation and the residual sugar, ABE concentration and ABE yield were calculated after fermentation (FIG. 1). The initial concentration of sugars was similar for all samples, with approximately 9.6, 11.2, and 9.9 g / l glucose, xylose and arabinose. No growth or gas production was apparent at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com