Polymer Food Packaging

a food packaging and polymer technology, applied in the direction of non-metal conductors, containers preventing decay, conductors, etc., can solve the problems of ineffective prevention of food product ripening, no existing food packaging material inhibits the ethylene formulation, and quick degradation, so as to prolong the shelf life of fresh food products, enhance the taste of fruits/vegetables, and reduce the rate at which fresh food products ripen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

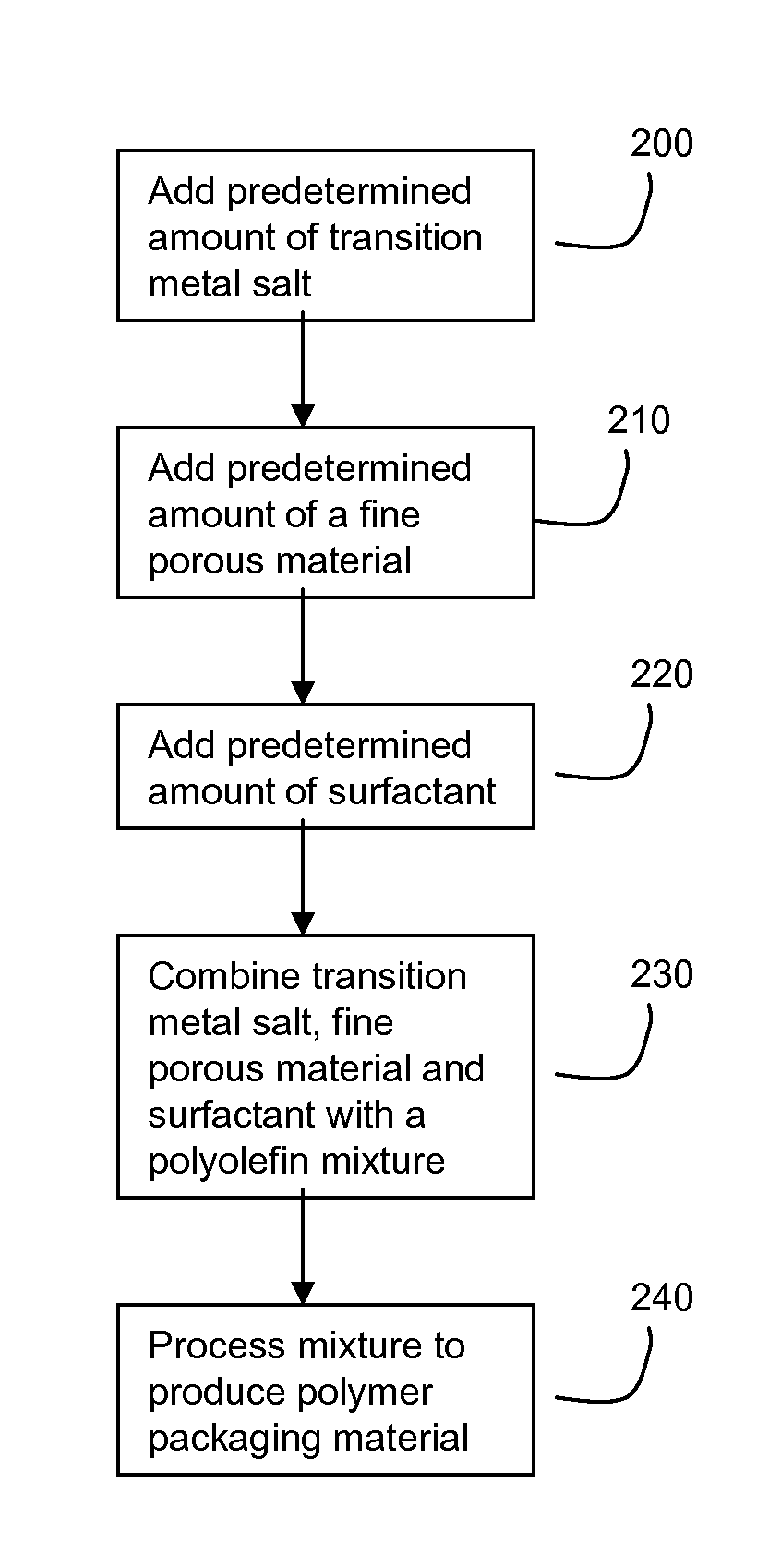

Method used

Image

Examples

example 1

[0032]

Element% by weightpolyolefins (polyethylene or polypropylene) 99.5-91a transition metal salt0.05-3a fine porous inorganic material0.05-3a surfactant0.05-3

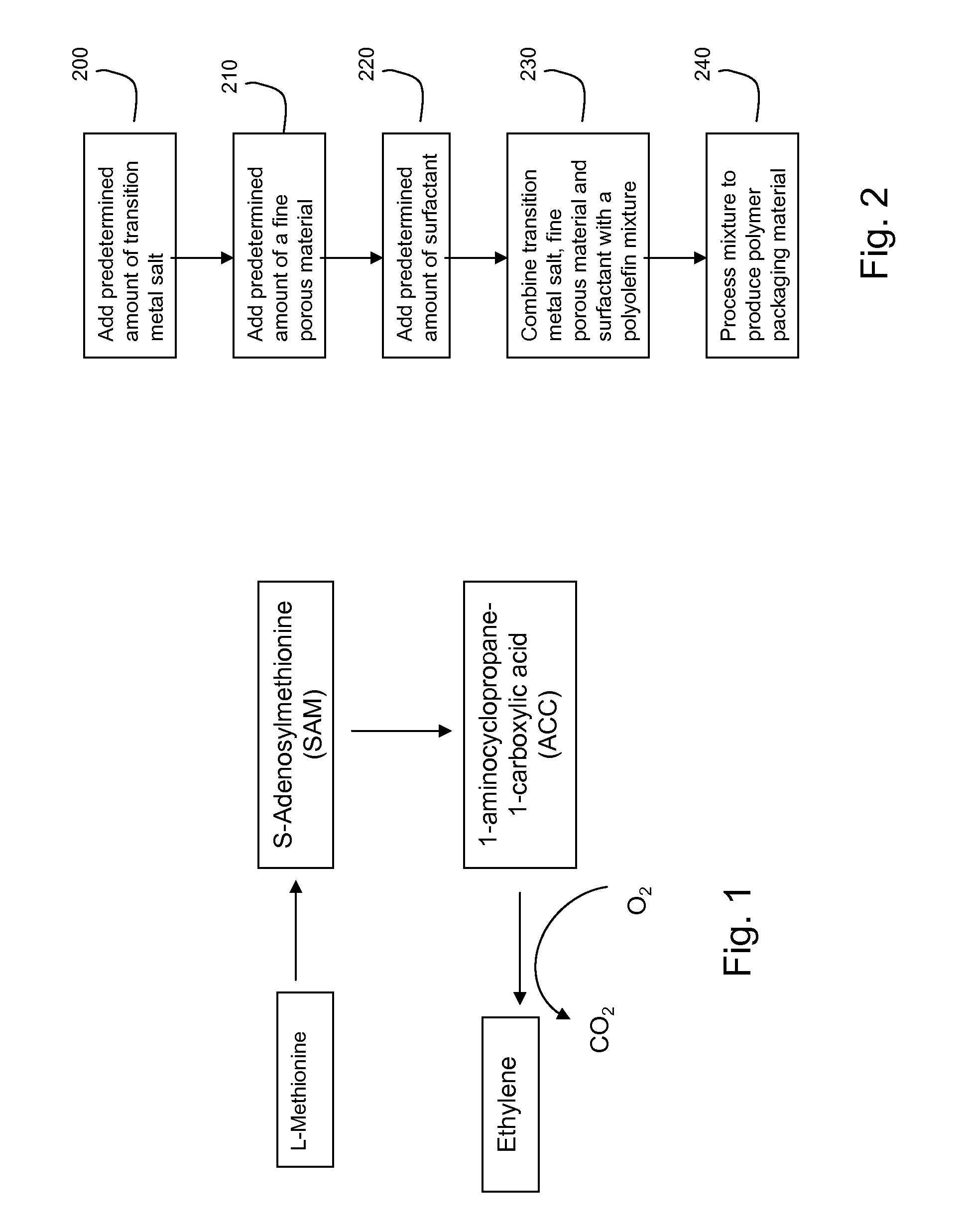

[0033]In addition to, or in the alternative, the above polyolefin element may also include polylolefinic copolymers such as EVA, EMA, etc. or other semi-transparent polymers such as EVOH, PLA, PHA, etc. The transition metal salt may include any transition metal, including but not limited to Manganese, Iron, Cobalt, Nickel, Silver or Copper, combined with a fatty acid including but not limited to stearic, oleic, palmitic, myristic, behenic or other fatty acid. The composition may use all derivatives and sources of transition metals because the ethylene inhibitor is the transition metal ion. The fine porous inorganic material may include any of silica, zeolite, cristobalite, Calcium carbonate, Kaolin, Talc and Limestone. The surfactant may be composed of glycerol, glycol, glycerol esters or blends of these or with other polyhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com