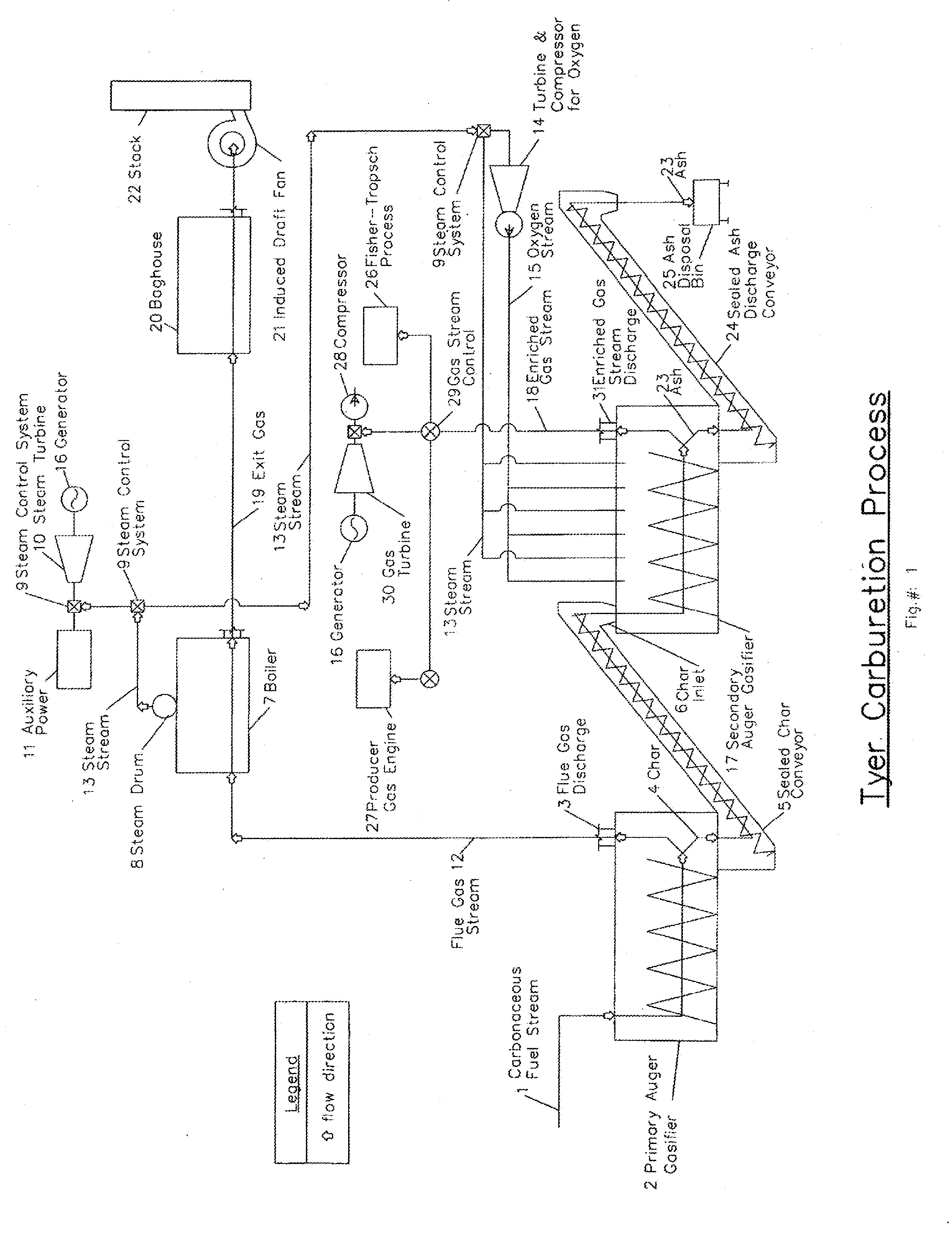

Tyer carburetion process

a carburetion process and gasifier technology, applied in the field of fluidized bed gasifiers, can solve the problems of insufficient processing of most starved-air gasifiers, inability to meet the requirements of use, and high cost, so as to achieve accurate control of fuel movement, reduce the pitch of the auger, and maximize the exposure to oxidation and/or gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment one

; OPERATIONAL DESCRIPTION

[0048]A carbonaceous fuel stream is introduced into the primary auger gasifier, advanced, agitated and tumbled by an auger, partially gasified and creates a flue gas stream and char product. The char product is collected from the primary auger gasifier, conveyor and delivered into the secondary auger gasifier. As said primary auger gasifier produces the flue gas stream that exits the flue gas discharge from the primary auger gasifier, said gases are directed to the boiler for steam production. After leaving said boiler, the flue gas stream, now an exit gas is cleaned and discharged. Concurrently, the steam stream also exiting the boiler steam drum, controlled by the steam control system directs steam stream to provide steam either into the steam turbine, which powers an electrical generator, and / or for auxiliary power. When required, for the water gas shift reaction, steam control system can direct both the steam stream into the secondary auger gasifier's do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com