Method of fixing carbon dioxide

a carbon dioxide and carbon dioxide technology, applied in the field of carbon dioxide fixing methods and systems, can solve the problems of long reaction time, difficult to find landfills for disposal, and buried slags, and achieve the effect of improving reaction efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

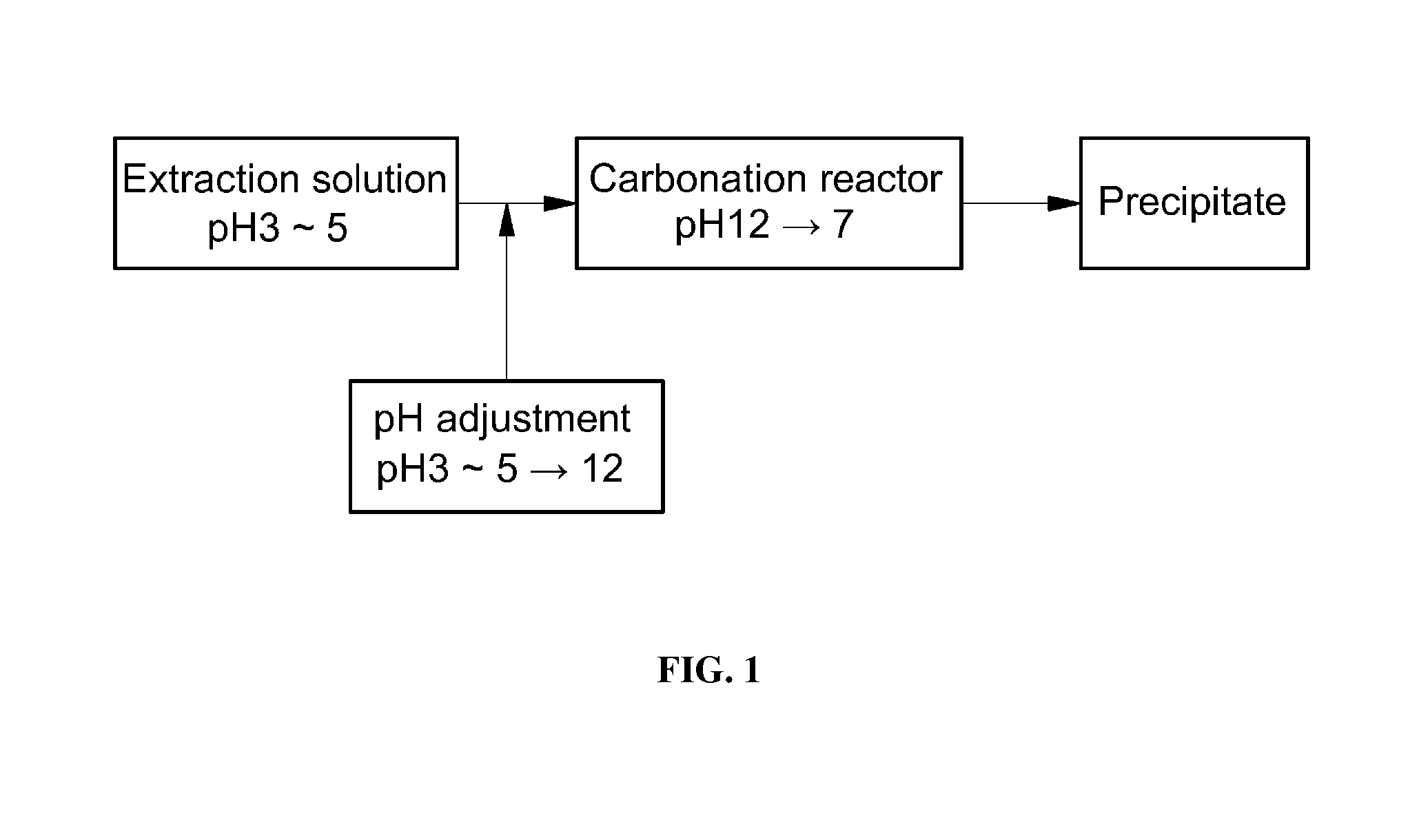

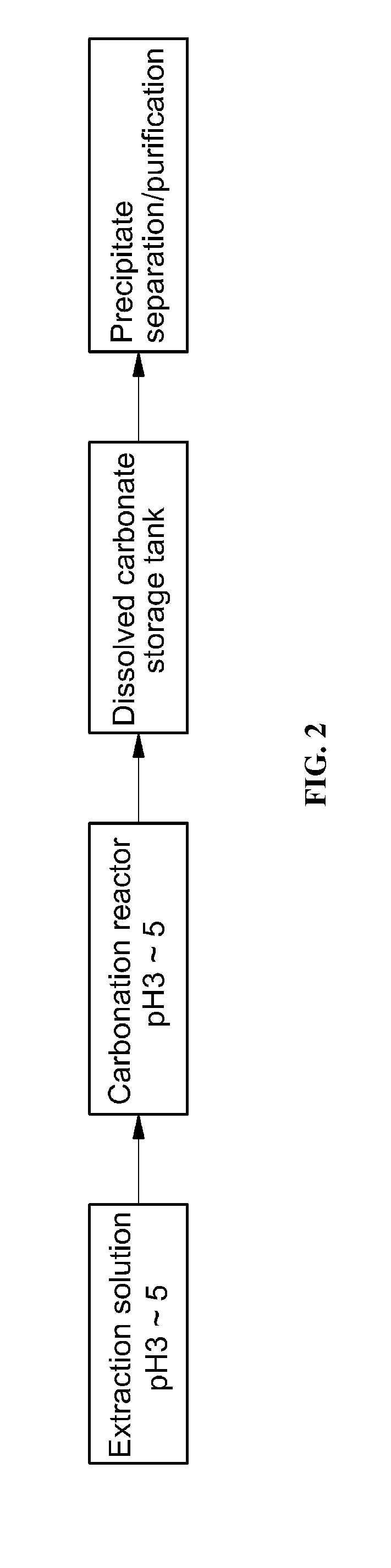

Method used

Image

Examples

example

[0029]Metal ion components were extracted from steel slag with a particle size of 1-5 mm using 10 vol % acetic acid at pH 3-5. The weight ratio of the extraction solvent to the slag was 10:1, and stirring rate was 150 rpm. Change in calcium ion concentration with extraction time is shown in Table 2.

TABLE 2Extractiontime (hr)123Calcium ion concentration (mg / L)26,00038,00038,000

[0030]As seen from Table 2, the extraction of the metal ions by the acid treatment was completed in about 2 hours.

[0031]Carbonation (carbon dioxide fixing) was carried out by injecting carbon dioxide to the resulting extraction solution. Carbonation was performed at 25° C. (77° F.) and 1 atm with the flow rate of carbon dioxide maintained at 2 L / min Change in calcium ion concentration and pH with carbonation time is shown in Table 3.

TABLE 3Carbonation time (min)11.522.533.544.5Calcium ion con-38,00022,00018,00016,00013,50013,20013,00013,000centration (mg / L)pH3.713.903.984.024.064.104.144.22

[0032]As seen from Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| alkaline | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com