Collection Systems for Use in Offset Pit Latrines Having Pour Flush Latrine Pans, Collectors, Offset Pit Latrines and Related Methods

a collection system and latrine pan technology, applied in sewer systems, water installations, construction, etc., can solve the problems of not meeting the criteria of basic or improved sanitation, individuals suffer significant adverse health effects, and individuals do not have regular and easy access to running fresh water or facilities,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

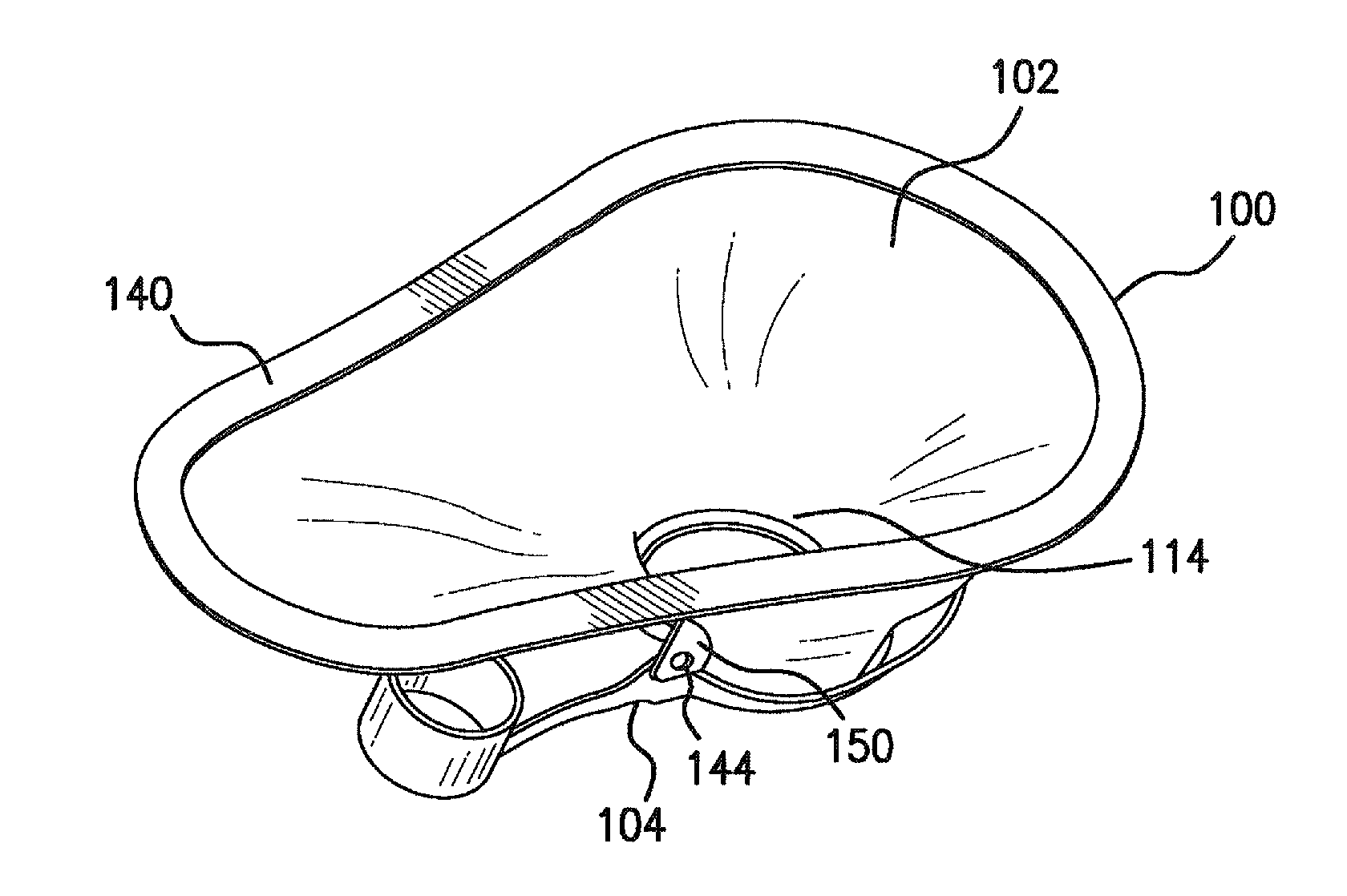

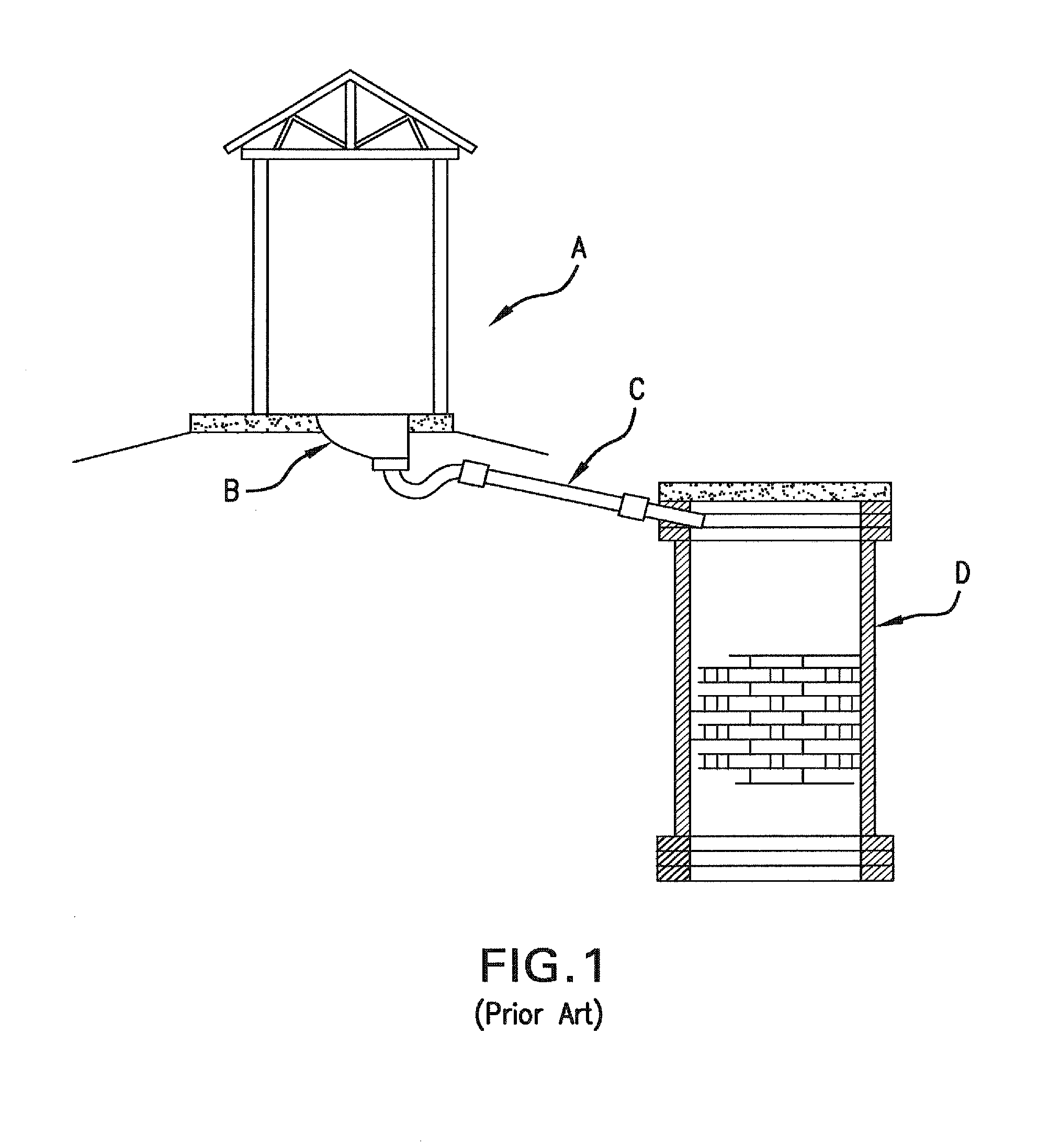

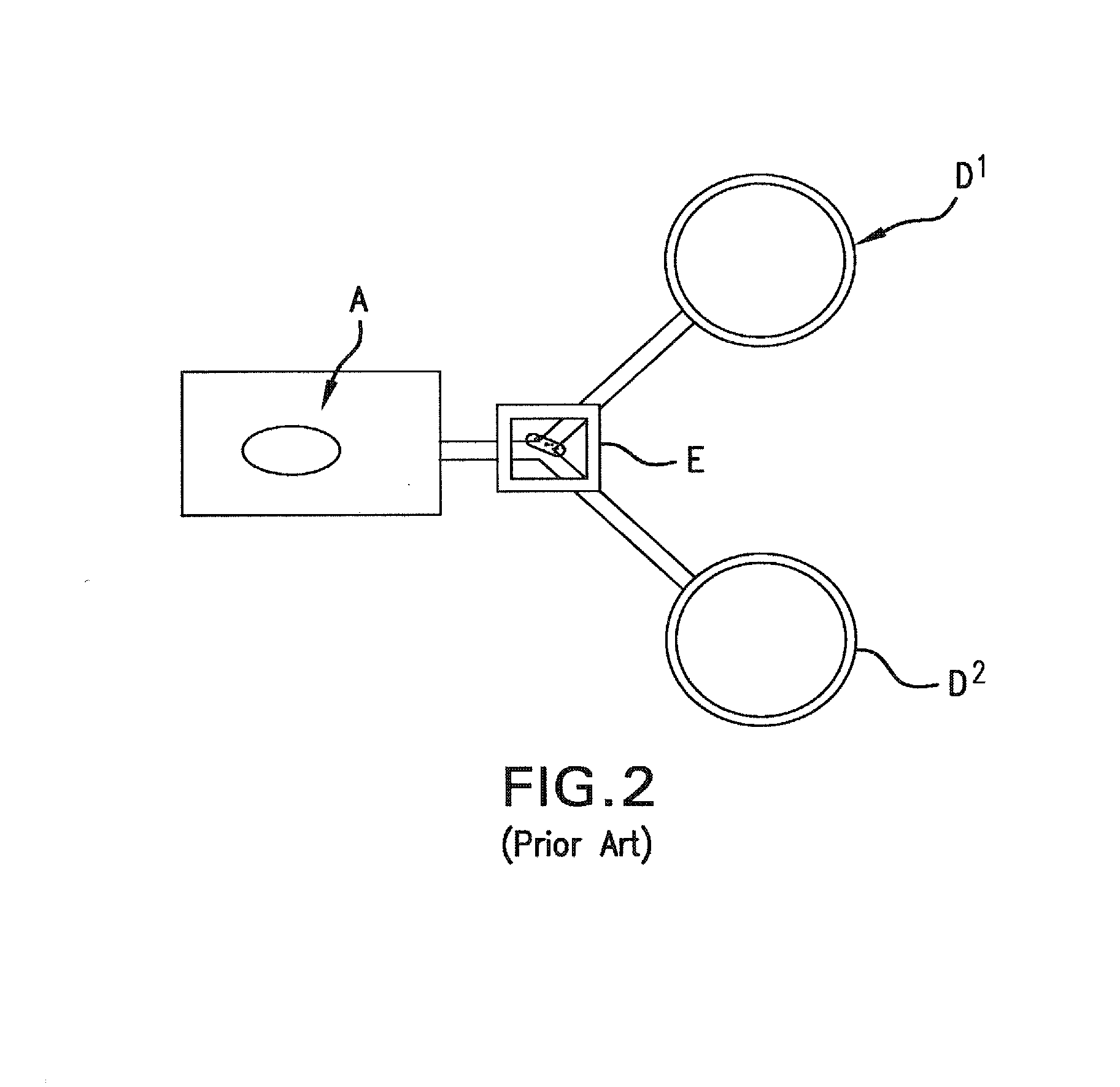

[0058]The invention described herein includes a system for use in an offset pour-flush latrine that comprises a latrine pan and a collector system. The system is advantageous as it can be inexpensively mass produced; it is lightweight but durable, so can be transported to remote areas at relatively low cost. The system is resistant to blockage under everyday use when installed as part of an offset pit latrine, prevents flying insects from passing in and out of the pit, and prevents or reduces the backflow of sewage gases from an offset leach pit into the squatting room or residence in which the pour-flush latrine pan is sited.

[0059]Also contemplated within the scope of the invention are offset pour-flush latrines, methods of reducing the incidence of adverse health effects, methods of preventing or ameliorating the flow of sewage gases, such as hydrogen sulfide or ammonia, from an offset leach pit, methods of installing the pour flush latrine pan into an offset pit latrine, and meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com