Method of electroplating low internal stress copper deposits on thin film substrates to inhibit warping

a thin film substrate and internal stress technology, applied in the direction of electrolysis process, electrolysis components, semiconductor devices, etc., can solve the problems of poor adhesion of the deposit, low ductility, stress and relief, etc., and achieve low internal stress and high ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0044]The following aqueous acid copper electroplating baths are prepared at room temperature.

TABLE 1ComponentBath 1Bath 2Copper sulfate160g / L160g / LSulfuric acid150g / L150g / LChloride (as hydrochloric acid)60ppm60ppmBis-sodium sulfopropyl disulfide4ppm03-mercapto-1-propane sulfonic6ppm0acid, sodium saltO-ethyldithiocarbonato)-S-0150ppm(3-sulfopropyl)-ester,potassium saltPolyoxy-alkylene glycol0.15g / L0.9g / LPolyethylene glycol0.18g / L1.1g / LBranched polyethylenimine0.75ppm0.75ppm(Mw = 25000)

[0045]The components of the copper electroplating baths are made up using conventional laboratory procedures where organics are added to water followed by adding the inorganic components. Stirring or agitation with heat application at temperatures of below 30° C. is done to be certain that all of the components are solubilized in the water. The baths are allowed to come to room temperature prior to copper electroplating. The pH of the acid copper electroplating baths ranges from less than 1 to 1 at roo...

example 2

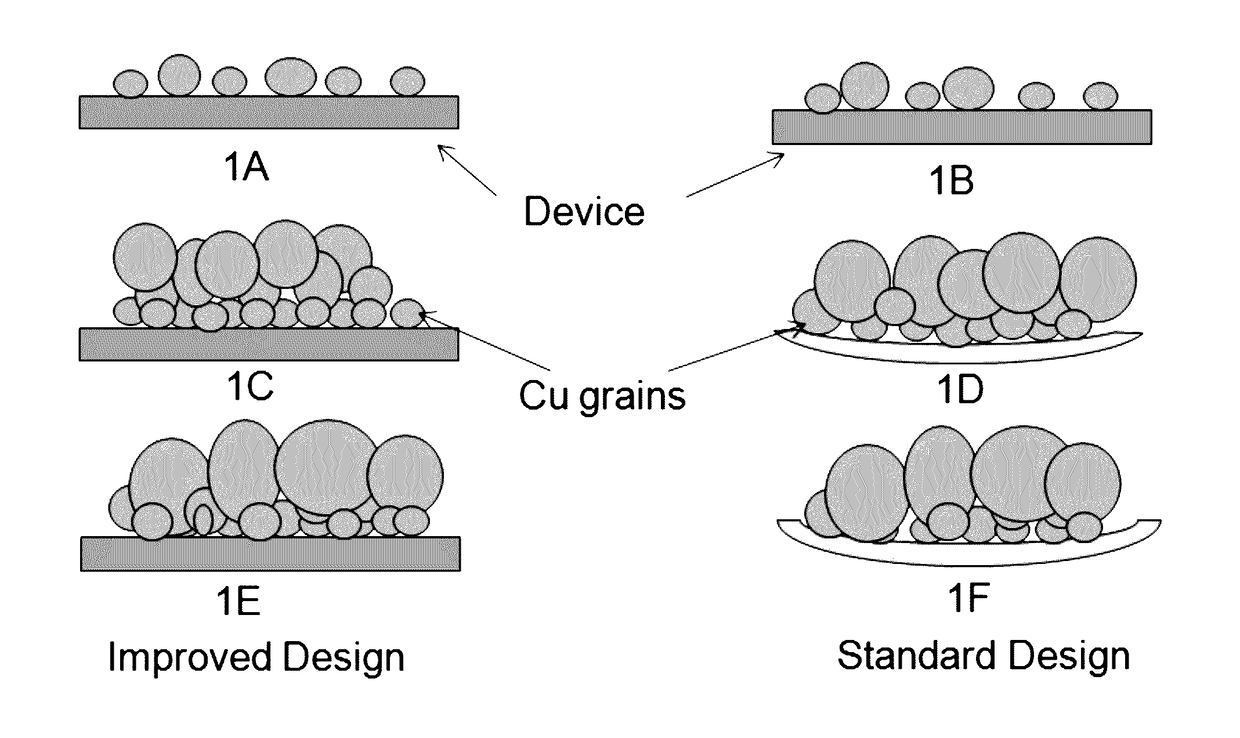

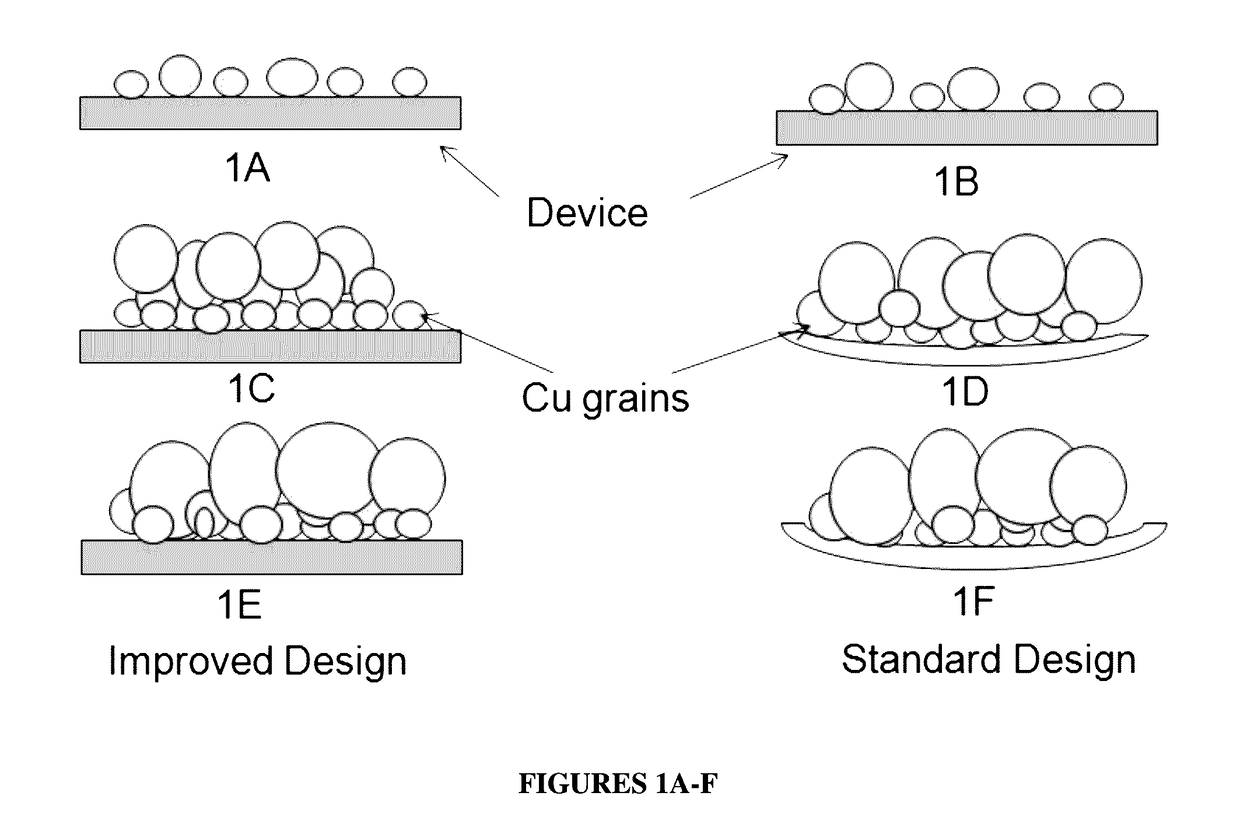

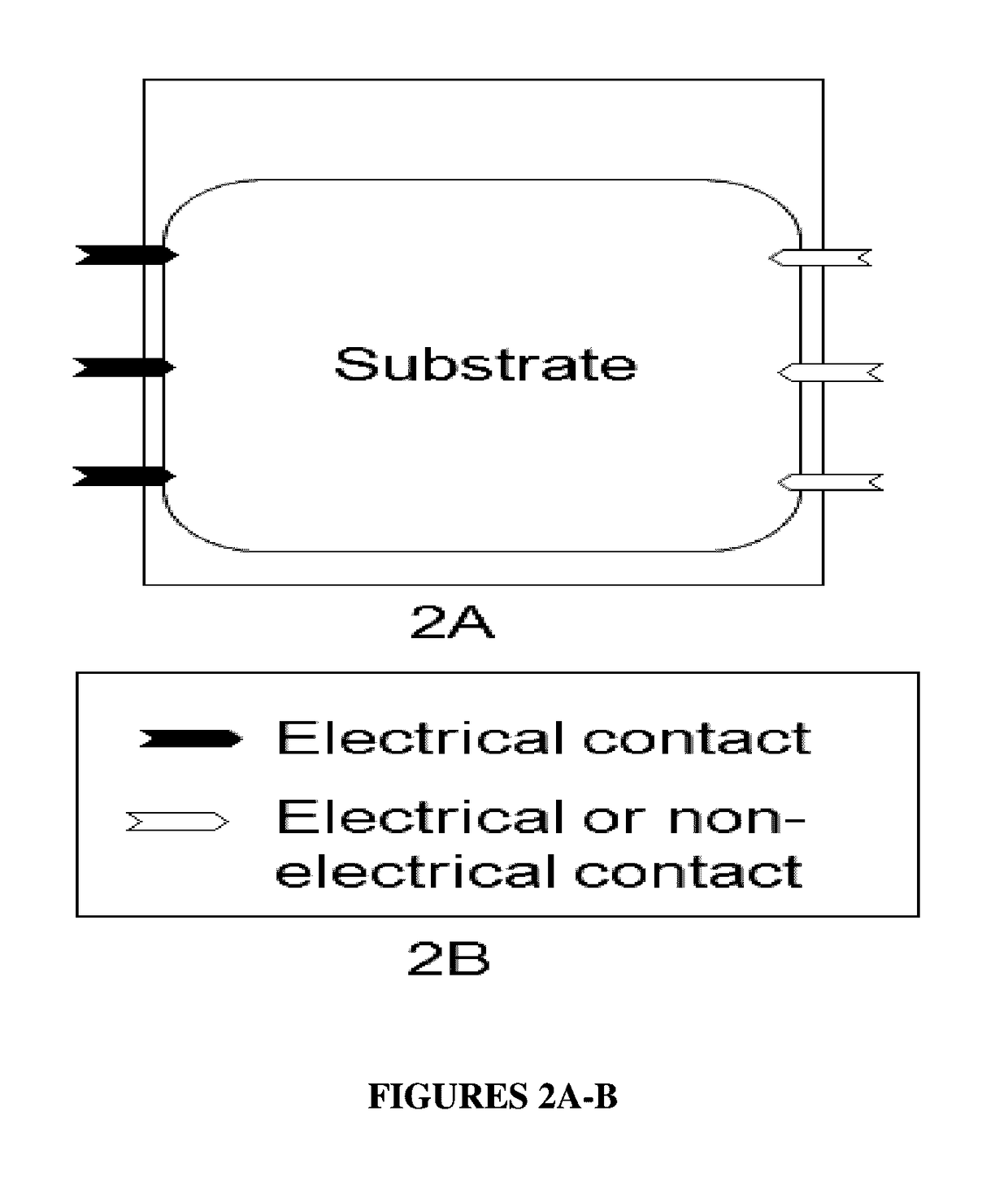

[0046]A plurality of thin films of copper having thicknesses of 100 μm are joined to non-conducting rectangular flat panel plating jigs as illustrated in FIG. 2A. Each thin film is secured to a flat panel plating jig by six electrical contacts, three on each side of the thin film or in the alternative by three electrical contacts and three non-electrical contacts as shown in FIGS. 2A and 2B. The non-conducting flat panel plating jigs with the thin films are secured to a conveyor system where the plating jig is joined to the conveyor such that it does not move outside a single plane and which transports the thin films through plating tanks which contain Bath 1 or Bath 2 as in Example 1. The thin films remain substantially in one plane during the electroplating process. When the thin copper films joined to the flat panel jigs pass into one of the two copper plating baths, the electrical contacts are placed under a potential from an electric rail which makes electrical contact with the...

example 3

[0047]The following aqueous acid copper electroplating baths are prepared at room temperature.

TABLE 2ComponentBath 3Copper sulfate160g / LSulfuric acid150g / LChloride (as hydrochloric acid)60ppm(O-ethyldithiocarbonato)-S-175ppm(3-sulfopropyl)-ester,potassium saltPolyoxy-alkylene glycol0.15g / L(PolyMax ™ PA-66 / LC solution)Polyethylene glycol0.18g / L(PEG 12000)Polyallylamine1.25ppm(Mw = 15000)

[0048]The components or the copper electroplating bath are made up using conventional laboratory procedures where organics are added to water followed by adding the inorganic components. Stirring or agitation with heat application at temperatures of below 30° C. is done to be certain that all of the components are solubilized in the water. The bath is allowed to come to room temperature prior to copper electroplating. The pH of the acid copper electroplating bath is less than 1 at room temperature and during copper electroplating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stress optical coefficient | aaaaa | aaaaa |

| Ductility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com